Vacuum Packaging Machine VC999 K7

Error display and troubleshooting

2008-11-26 Art.-No. 592.016 Page 79/121

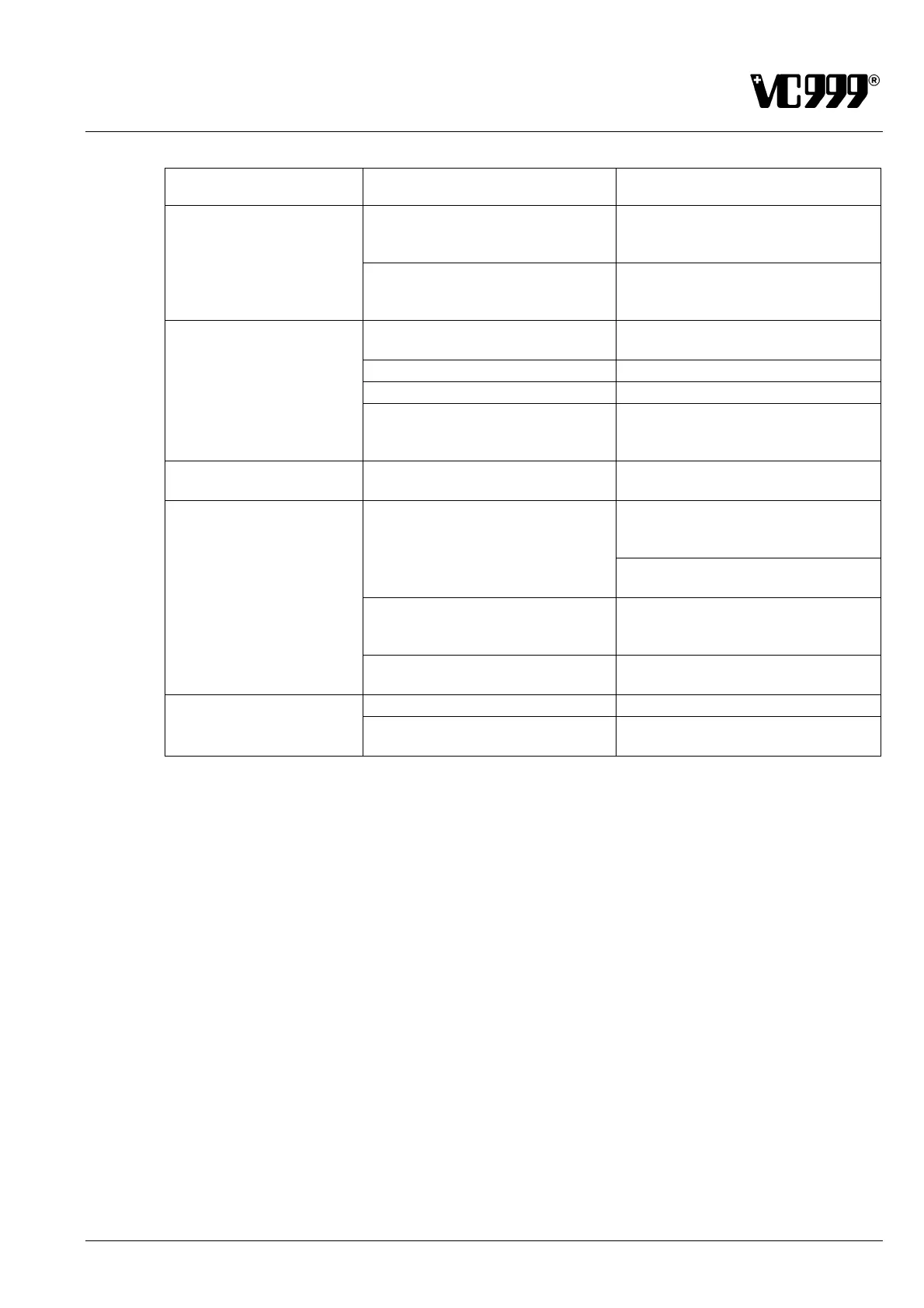

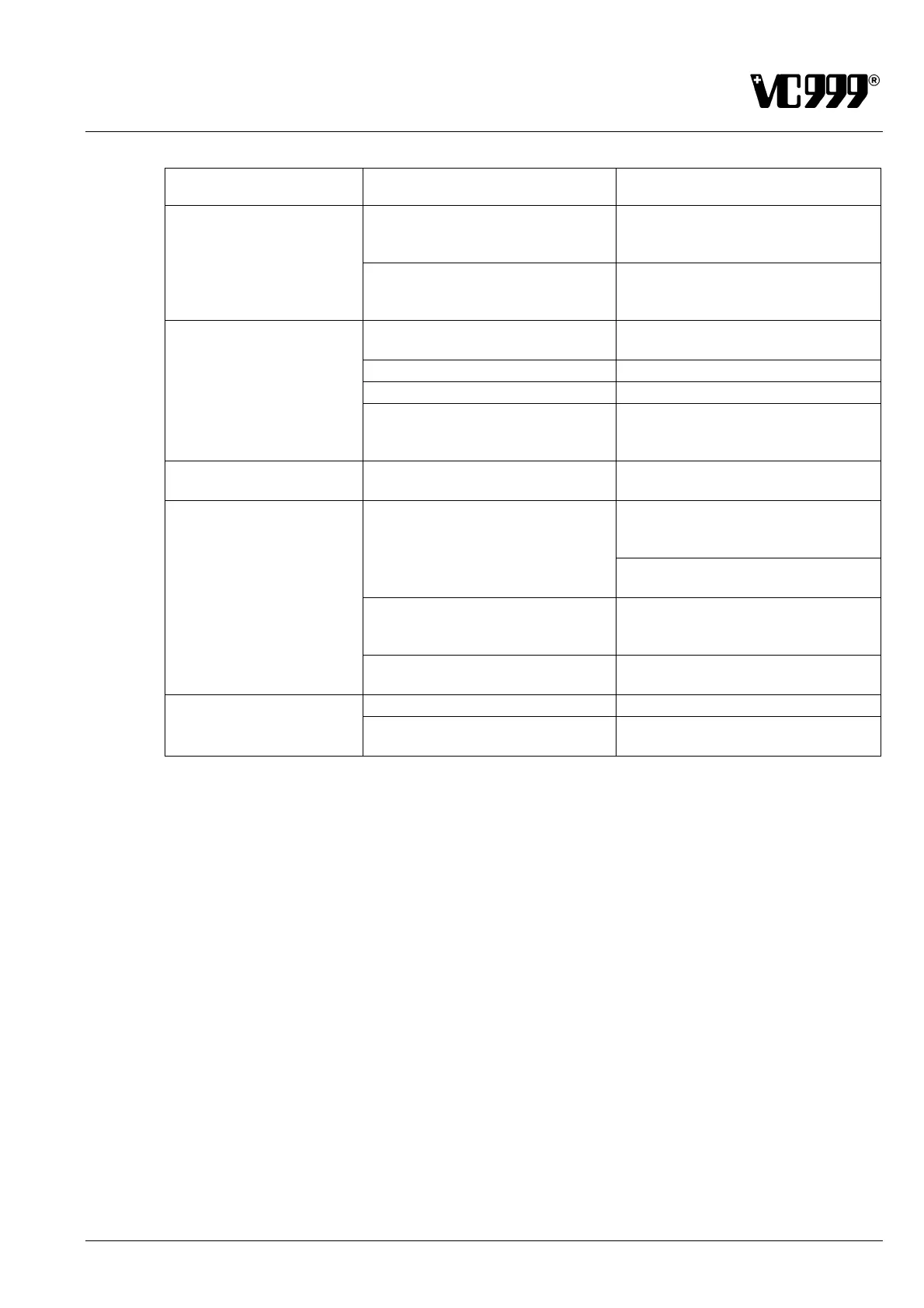

Fault Cause Remedy

Too little bag material between

packaging product and sealing

bars

Set bulky packaging goods 5 to 10

cm from guide rail to release load on

sealed seam in venting.

Sealed seams damaged or

completely separated

Sealed seam adheres to sealing

bar after sealing

Check Teflon tapes of the sealing

bars for wear, spray Teflon tapes

periodically with Teflon spray.

Circuit breaker of the sealing trans-

former is off or has tripped

Reactivate circuit breakers

Pressure valve does not open Check valve and drive

Sealing type set on OFF Set to ON

Sealing non-functional

Compression pressure too low

Compressed air regulator in power

supply box must be set at about 4.5

bar

Conveyor belt motor not

running

Transport type set on OFF Select a speed stage in the program

Check spacing between switching

sensor and belt; this should be 1-2

mm

Switching sensor for conveyor belt

positioning not operating correctly

Clean switching surface on sensor

switch

Conveyor belt slipping on drive

cylinder

Check belt tension, and if necessary

tighten with tensioning screws on tail

pulley

Conveyor belt running but

does not position the

products exactly in the

vacuum chamber

(Alarm-12)

Products not positioning between

markings on belt (Fig. 9/24)

Set products between markings on

belt

Incorrect step password Select correct step password

Program can neither be

loaded nor saved

Function "Time-based vacuuming"

is switched on.

Switch off function in Mask 157:

Defect modes.

Fuses

The fuses are located in the electrical cabinet (Fig. 3/1, pos. 10). Please read section 12.2 "Repairs to

electronics or control system" under "Replace fuses".

Loading...

Loading...