Vacuum Packaging Machine VC999 K7

Maintenance

Page 84/121 Art.-No. 592.016 2008-11-26

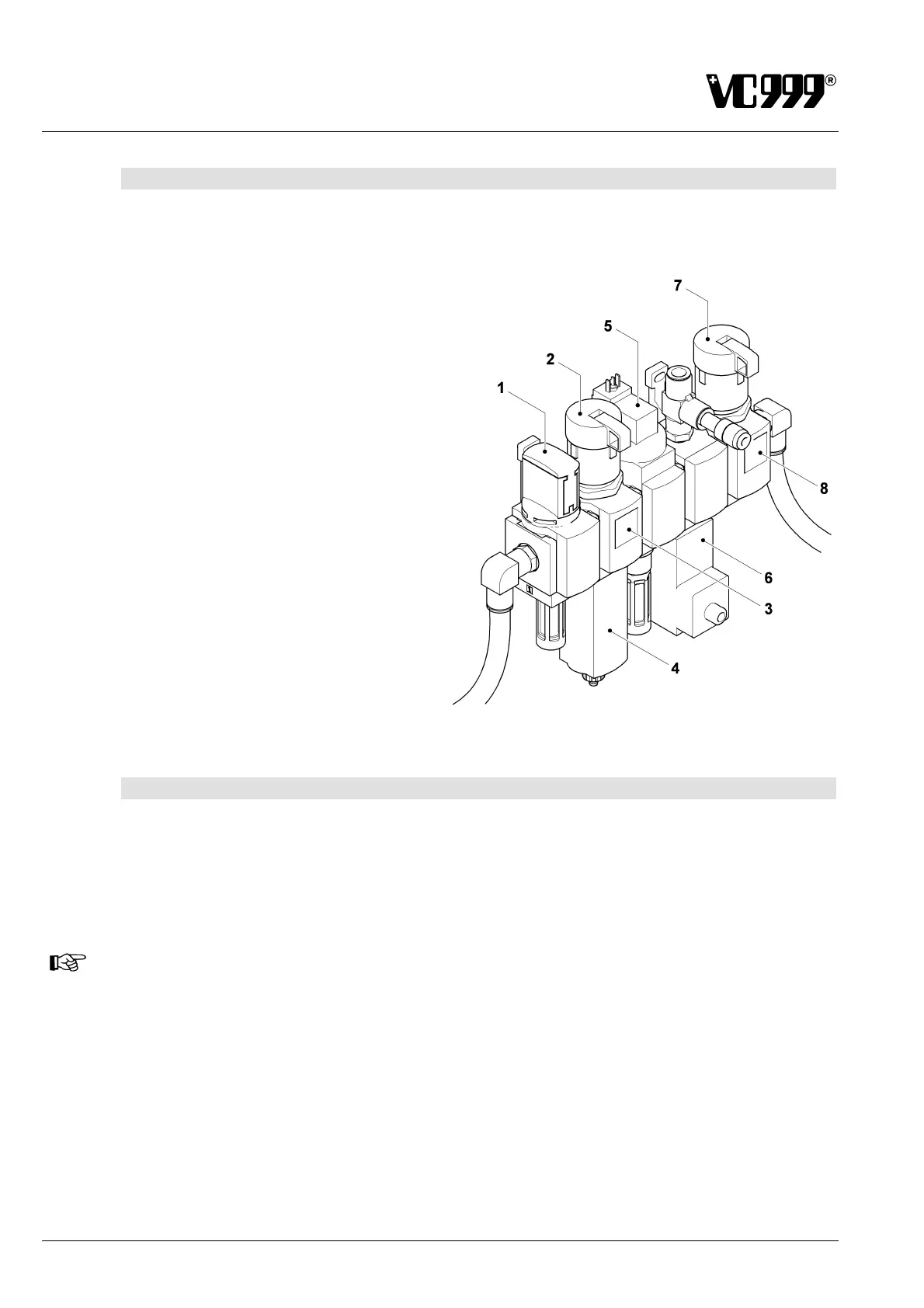

11.2.1 Compressed air maintenance unit

The compressed air maintenance unit is for cleaning and preparing compressed air. The system in-

cludes condensate extraction, pressure regulation and enrichment of compressed air with the requisite

oil mist. Die compressed air maintenance unit is located in the power supply cabinet.

Legend

1 Hand stop valve

2 Pressure controller

(machine operating pressure)

3 Pressure display

(machine operating pressure)

4 Condensate tank

with automatic drain function

5 Main valve (6Y6)

6 Compressed air monitoring (9B9)

7 Pressure controller (air cushion)

8 Pressure display (sealing bar)

Fig. 11/1

11.2.2 Maintenance sealing bars

Servicing the sealing bars includes replacing the Teflon tape or the sealing wire. The Teflon tape on the

sealing bars must be replaced if there are signs of scorching. It may be necessary to replace the sealing

wires at the same time. Please read section 11.2.2.1 "Replace Teflon tape and sealing wires".

New sealing bars, or bars with newly installed sealing wires, have to be calibrated and burnt-in after in-

stallation and prior to production. Please read section 11.2.2.2 "Calibration and burn-in sealing bars".

NOTICE

Keep a spare set of sealing bars so that these can be exchanged when necessary without major

interruptions to the production cycle and return to Inauen Maschinen AG for renewal.

Loading...

Loading...