Vacuum Packaging Machine VC999 K7

Maintenance

Page 82/121 Art.-No. 592.016 2008-11-26

11.1.2 Inspection work

With regular inspection, problems can often be identified before they interrupt production.

WARNING

Risk of injury to persons and damage to property. When routine checks are made with the Vac-

uum Packaging Machine in operation, the required safety instructions in chapter 2 “Safety,

warranty” must be observed!

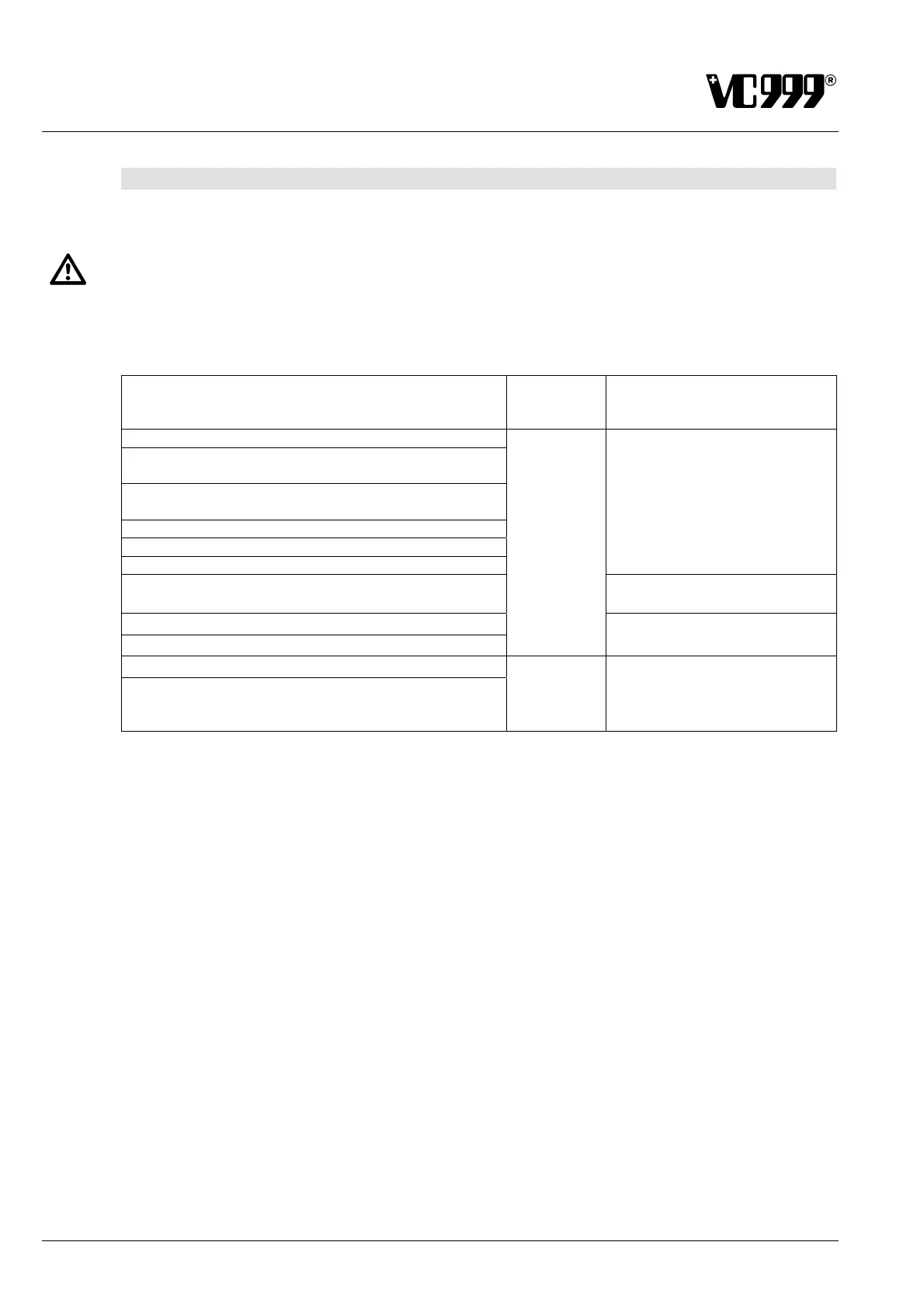

Task

Frequency

Documentation

General visual inspection

Check lid seal (this should seal all round and fit close-

ly in the groove)

Conveyor belt: Check belt run (centering) and belt

tension

Check Teflon tapes on top and bottom sealing bars

Check movement of vacuum chamber on closing

Check bolts for vacuum chamber centering

Check cutter blade (VC999 K7A) / perforation blade

(VC999 K7B) and pre-perforation blade

Chapter 11.5 „Maintenance

blades“

Bag waste suction: check level in bag waste container

General acoustic inspection (Noise emission)

daily

Check oil in vacuum pumps for color change

Check oil level in vacuum pump(s)

weekly

According to instructions, see

separate user manual of the

pump manufacturer under the

"Vacuum pump" index tab.

Loading...

Loading...