Vacuum Packaging Machine VC999 K7

Maintenance

2008-11-26 Art.-No. 592.016 Page 87/121

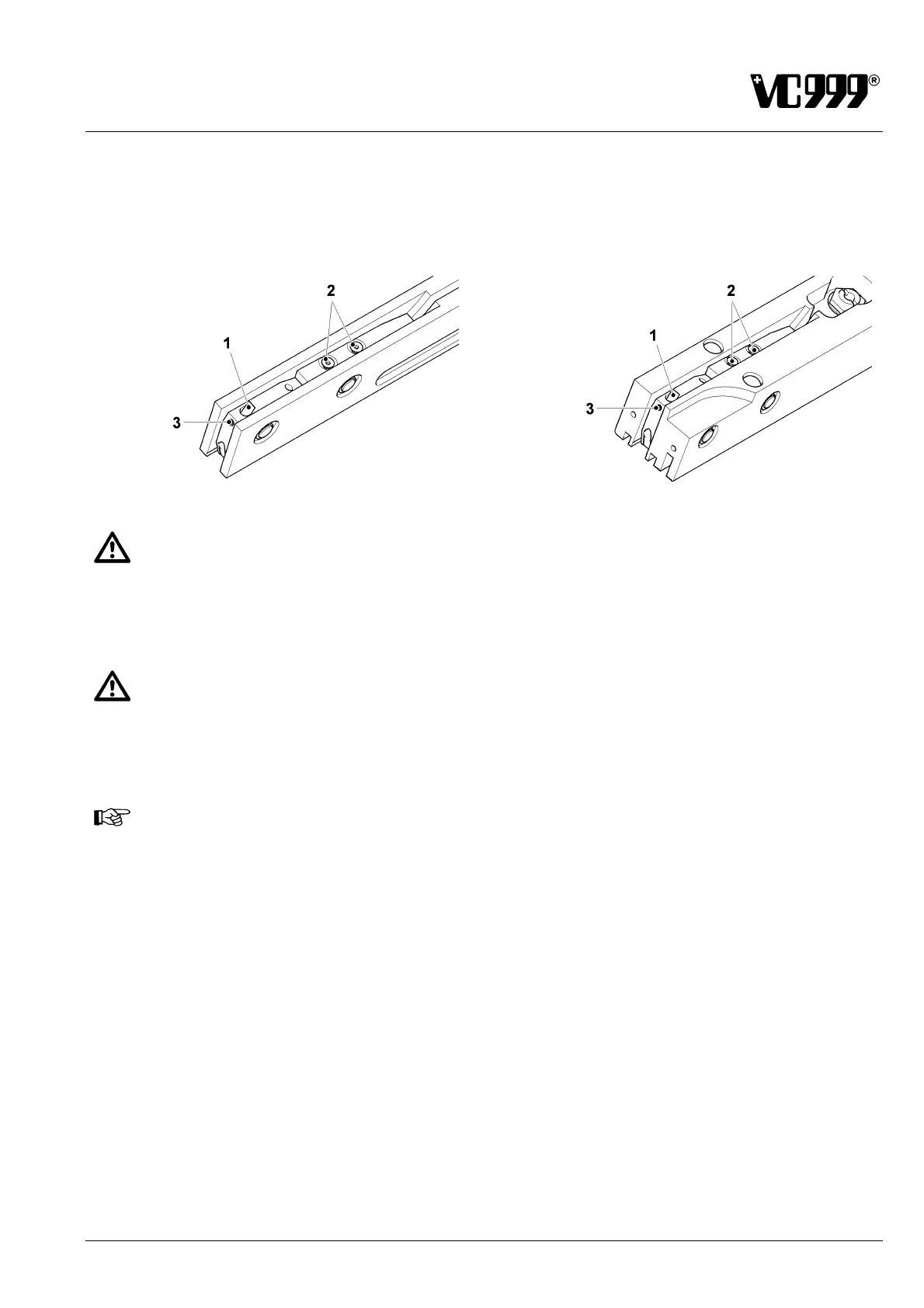

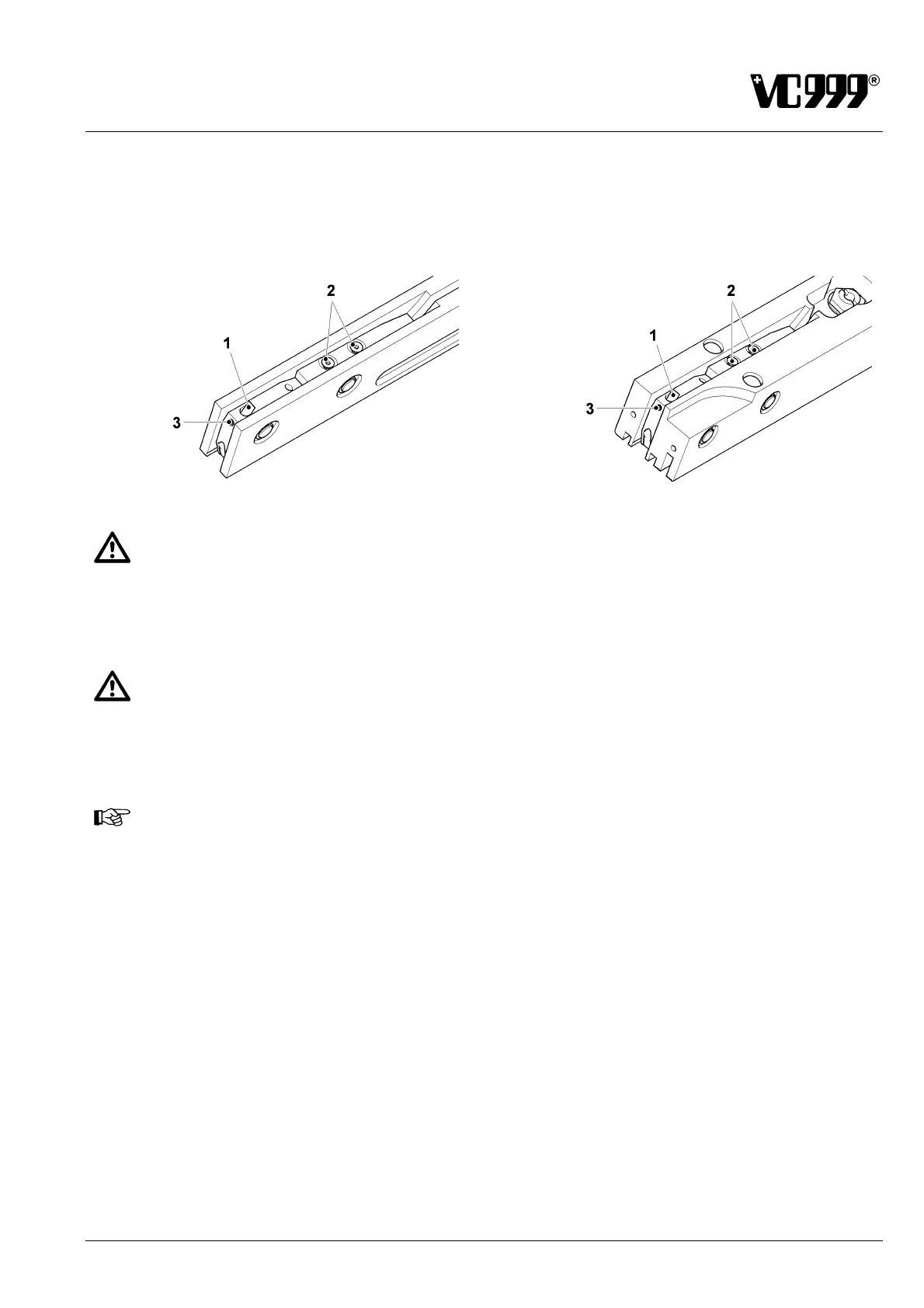

2. Remove sealing wire by unscrewing the grub screw (3) and withdraw (1).

3. Insert new sealing wire, pull tight and screw in position with grub screw (3).

Upper sealing bar Lower sealing bar

Fig. 11/4

CAUTION

Risk of short-circuit with projecting wire end. Bend the protruding wire end right back into the

sealing bar.

4. Tension the sealing wire by tightening the counter-sunk screws (2).

NOTICE

Ensure that the sealing wire does not have electrical contact to the aluminum bar.

5. Insert a new Teflon tape and install the sealing bar in the machine as described above "Replacing

Teflon tape lower sealing bar", or "Replacing Teflon tape upper sealing bar".

NOTICE

If sealing bars with new sealing wires have been installed in the machine, the following proc-

esses have to be carried out one after the other:

Calibration sealing bars – Burn-in sealing bars – Allow sealing bars to cool down – Calibration

sealing bars.

6. Calibrate and burn-in the sealing bars. Please read section 11.2.2.2 "Calibration and burn-in seal-

ing bars".

Loading...

Loading...