Electrical Troubleshooting Procedures LTC Repair

wc_tx000429gb.fm 130

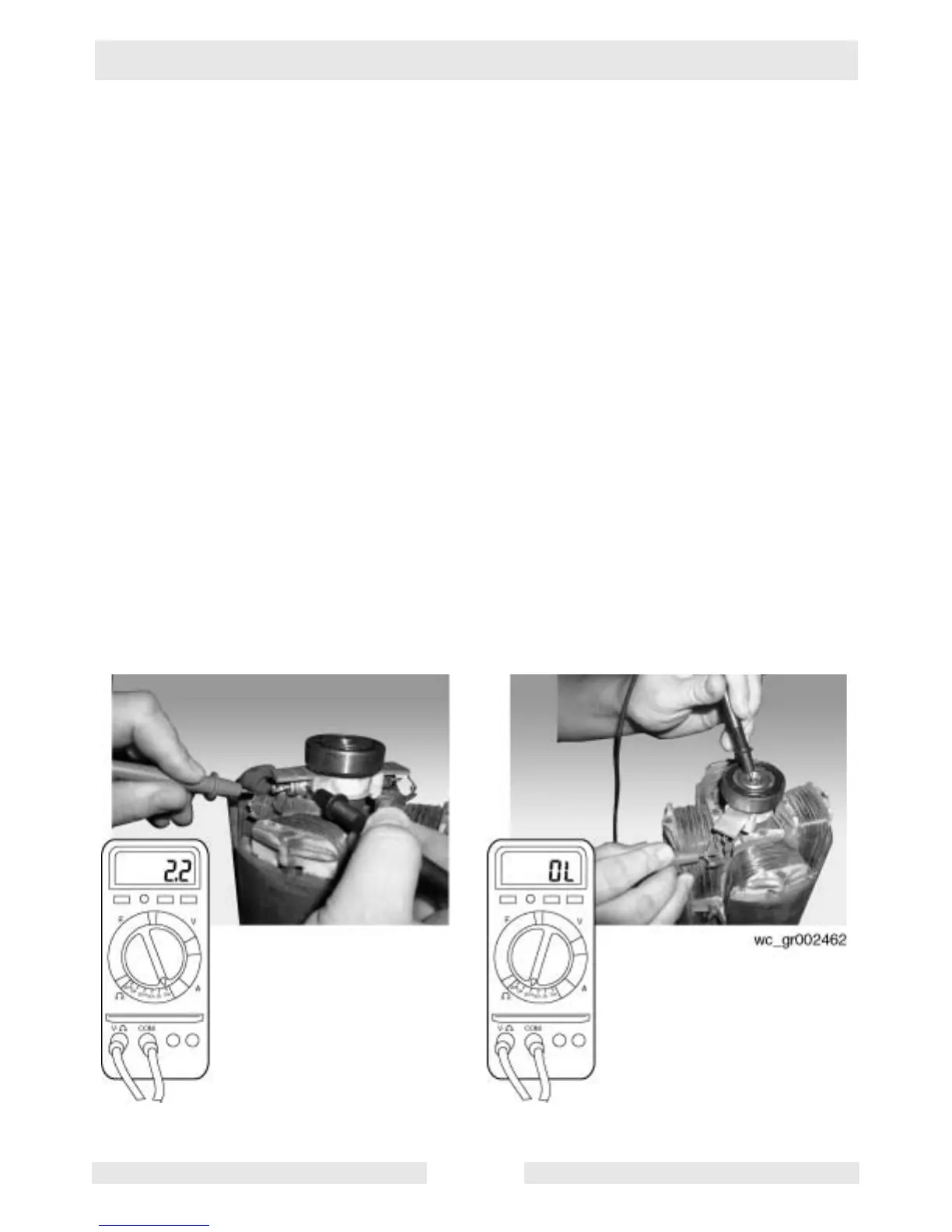

7.34 Checking Rotor Windings

See Graphic: wc_gr002462

After checking the two rotor diodes, check the rotor windings. The

engine/generator assembly must be removed and the stator must be

separated from the rotor to check the rotor windings.

7.34.1 Unsolder the two rotor winding wires from the terminal end of each

diode.

7.34.2 Using the Ohms setting on the multimeter, measure the resistance

across the wires and the base of the corresponding diode. Each wire

reading should be 2.2+0.5/-0.0 Ohms or greater. If your readings are

not 2.2+0.5/-0.0 Ohms or greater, replace the generator.

7.34.3 Check the resistance of all four rotor windings in this manner.

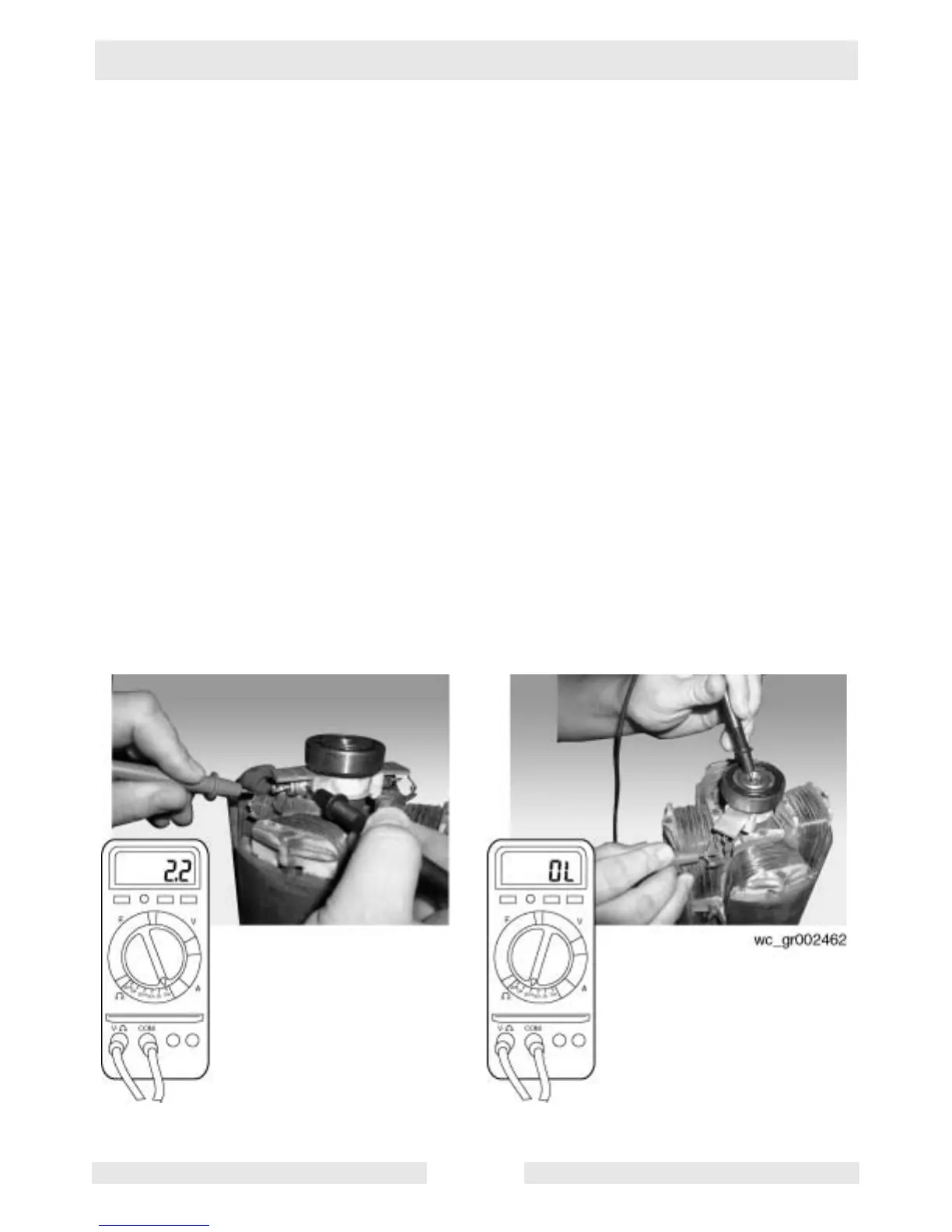

7.34.4 Also check the resistance across the wires and the rotor shaft. If your

readings are not OL, or greater than 2 megohms (2M Ohms), replace

the generator. Confirm with factory before replacing.

7.34.5 Check all four wires in this manner.

For a more thorough insulation test, use a megger meter capable of

500 Volts or have a motor repair shop test it. If readings are 2

megohms (2M Ohms) or greater, rotor is good. If readings are less

than 2 megohms, replace the generator end. Consult factory to

confirm.

Loading...

Loading...