Electrical Troubleshooting Procedures LTC Repair

wc_tx000429gb.fm 126

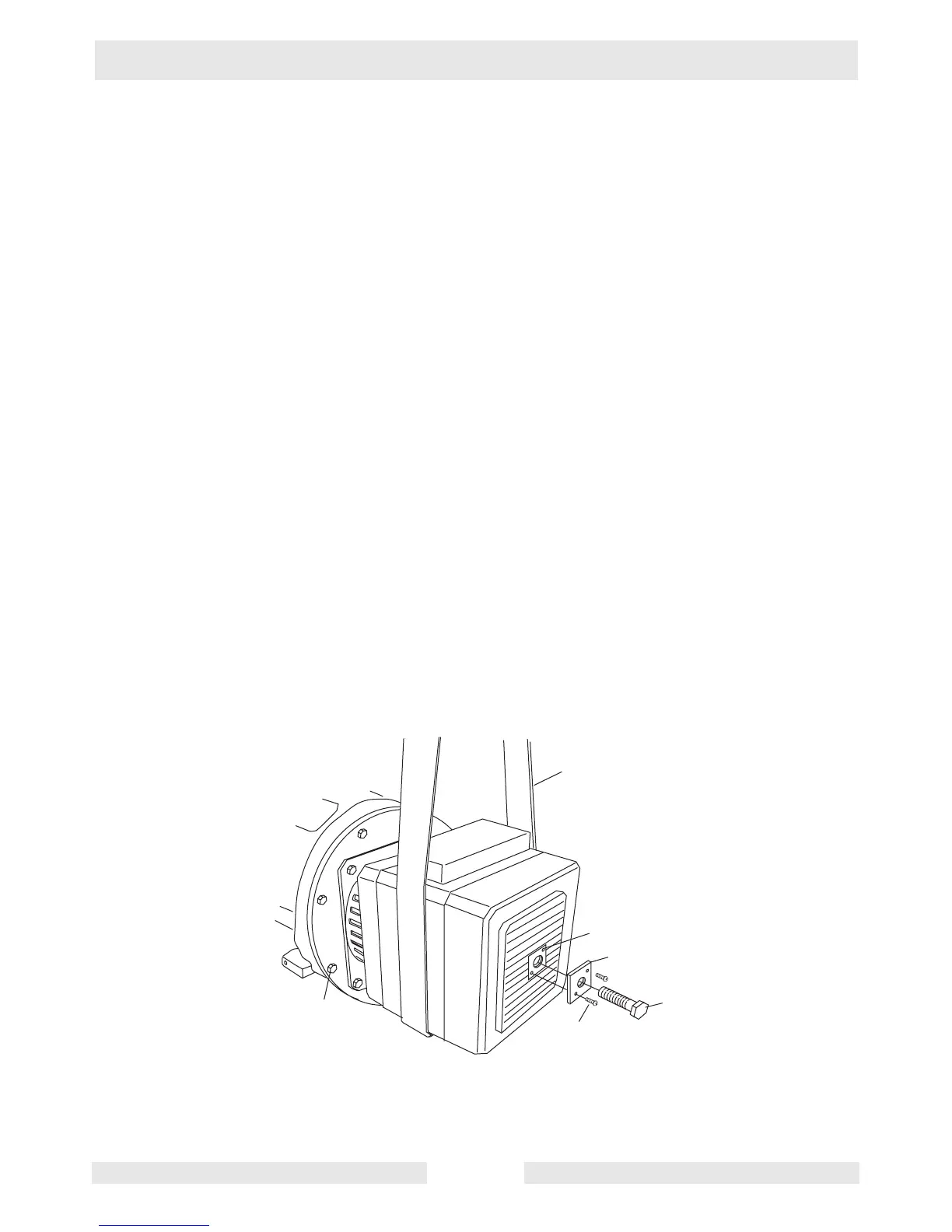

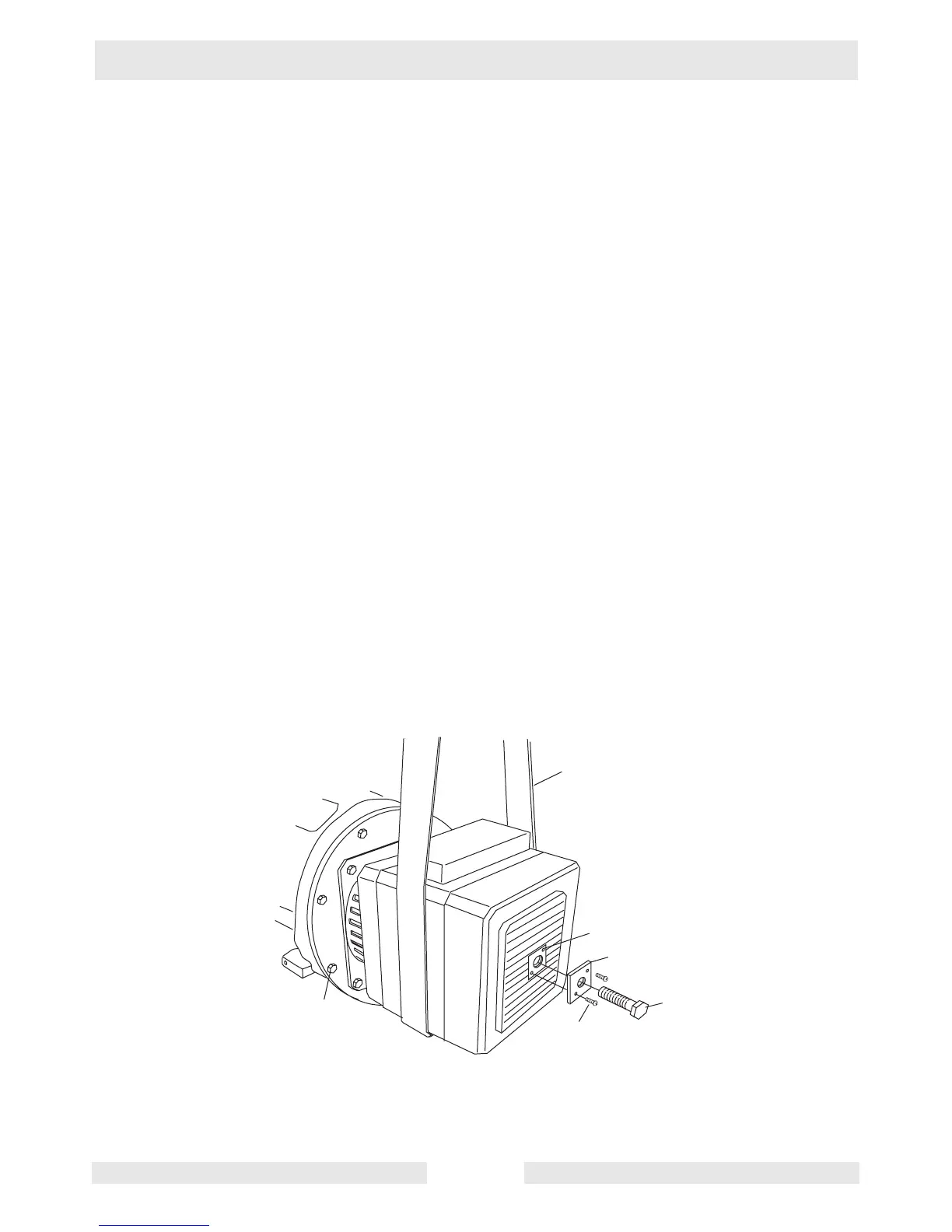

7.31 Separating Stator Assembly from Engine/Rotor Assembly

See Graphic: wc_gr001640

Note: The fit between the rotor bearing and the stator housing is tight.

The tight fit prevents the bearing from spinning in the housing.

7.31.1 There are two methods to separate the stator assembly from the

engine/rotor assembly. The first method involves creating a special

pusher tool. When using either method, support the stator assembly

with an appropriate strap and hoist.

Method 1

7.31.2 Using an appropriate strap (a) and hoist, support the generator end.

7.31.3 Using an approximately 3" x 3" (8cm x 8cm) piece of steel or aluminum

plate (b), drill a pilot hole in the center of the plate to accommodate an

M14 thread. Tap the hole in the plate with M14 threads.

7.31.4 Drill two holes in the plate whose placement matches those in the

stator housing (f).

7.31.5 Tap the holes (f) in the stator housing and using two screws (c) of the

same thread, secure the 3" x 3" plate to the stator housing.

7.31.6 Remove the M8 bolts (d) securing the engine adapter flange to the

engine.

7.31.7 Using an M14 bolt (e), thread it into the M14 threaded hole of the plate

and slowly pull the stator assembly from the engine/rotor assembly.

Loading...

Loading...