17

Wegaconcept

Technical manual

ENGLISH

6 Automatic Water Entry

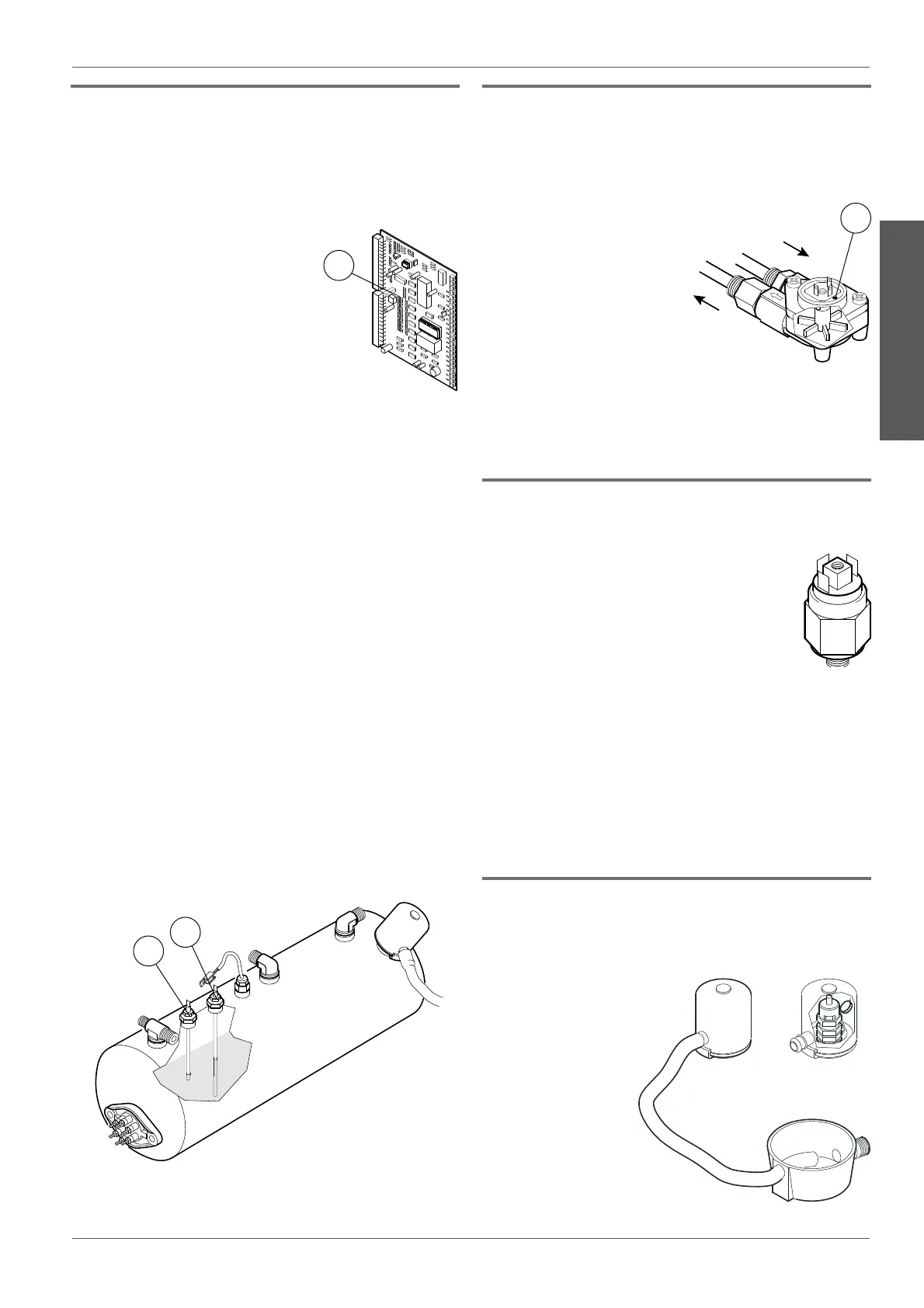

The Automatic Water Entry system is for checking the

boiler level. It is composed of:

t level probe (short) (1)and safety probe (long) (2) in-

serted in the boiler, composed of a stainless steel rod;

electronic control unit (3) ;

t hydraulic circuit controlled by

a motor pump and a solenoid

valve controlled by the elec-

tronic control unit.

When, during the normal

operation of the machine, the water

level drops down, the level probe

(1) sends a signal to the electronic

control unit (3), which activates the motor pump and the

lling solenoid valve, thus restoring the level of water in

the boiler.

If the level is very low or there is no water in the boiler

(during the machine's installation or due to a failure),

the safety probe (2) sends a signal to the control unit

which de-activates the heating element to keep it from

overheating and activates the motor pump and the

solenoid valve to restore the level of water in the boiler.

To avoid possible flooding due to machine

malfunctions or leaks in the hydraulic circuit, the

electronic control unit includes a timing device that cuts

o automatic lling after a maximum operating time

(roughly 30 seconds). During the installation of machines

with three or four groups the initial water lling time

may exceed the established time limit. In this event,

just switch the machine o and then back on to restore

normal operating conditions.

1

2

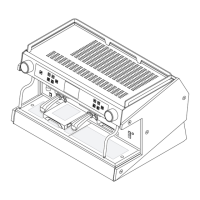

7 Volumetric dosing

The volumetric dosing device serves the purpose of

measuring the quantity of water sent to the group of

espresso delivery.

The dosing device

generates an electrical

impulse which is sent to the

electronic control unit.

This impulse is read by the

control unit and memorized

during the programming of

the dose.

The ashing of the LED (1)

indicates that the electrical impulse has been sent from

the dosing device to the control unit.

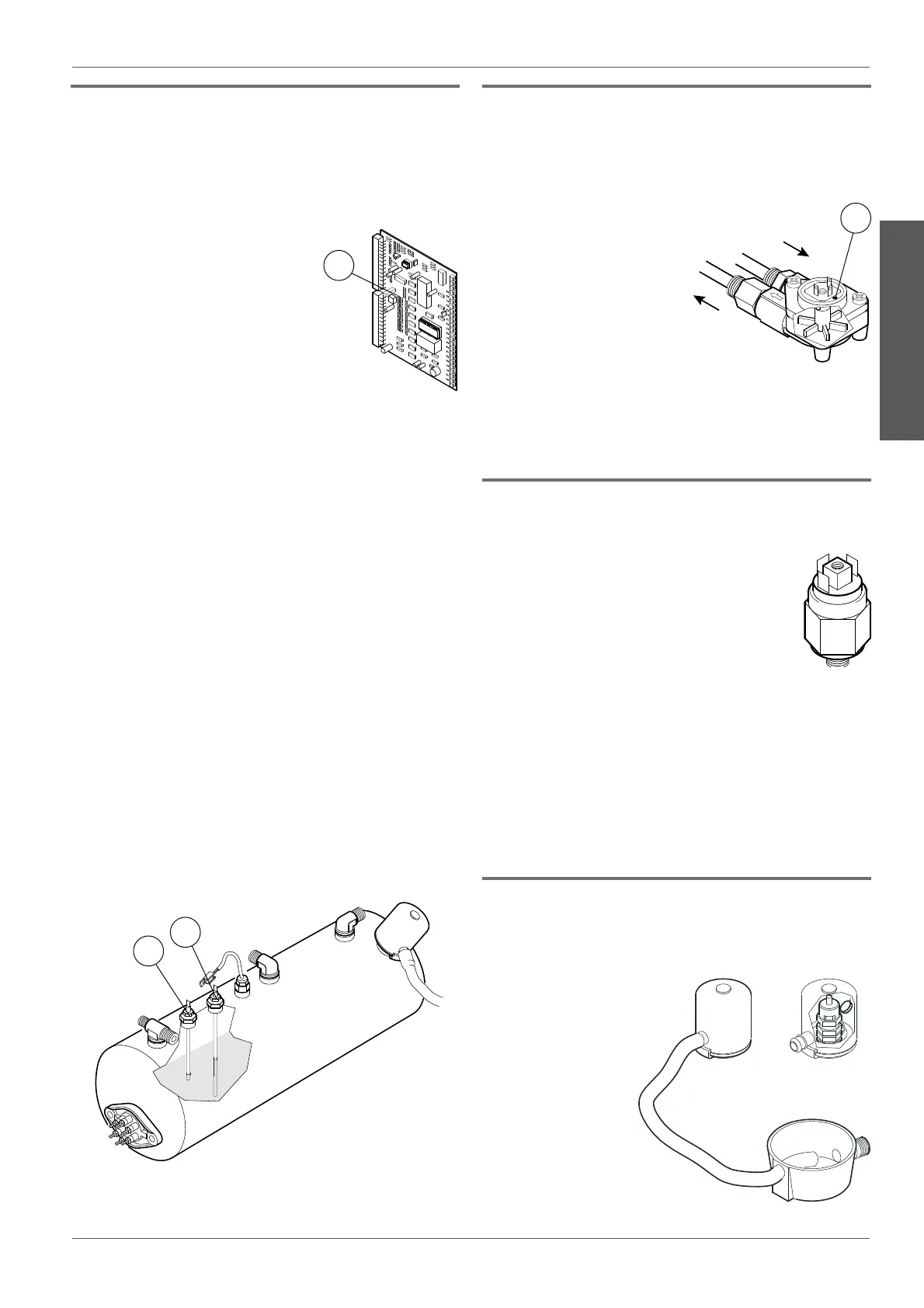

8 Pressure switch

The machine includes two types of pressure switches:

COFFEE BOILER PRESSURE SWITCH

Each coffee boiler is equipped with a

pressure switch to control the pressure.

Calibration is set to 5 bar and can be

distinguished by the green seal.

SERVICES BOILER PRESSURE SWITCH

also the boiler is equipped with a pressure

switch to control the pressure.

Calibration is set to 1.5 bar and can be distinguished

by the red seal.

9 Anti-ooding device

The cover installed on the pressure relief valve

makes it possible to collect any water which may

leak from the boiler

due to malfunction

and channel it to the

drain pad, by means

of a special hose.

3

1

Loading...

Loading...