29

Wegaconcept

Technical manual

ENGLISH

Cleaning

Daily

Weekly

Monthly

BODY

Clean the panels of the body with a cloth dampened

in lukewarm water. Do not use abrasive detergents

which may scratch the surface of the body.

X

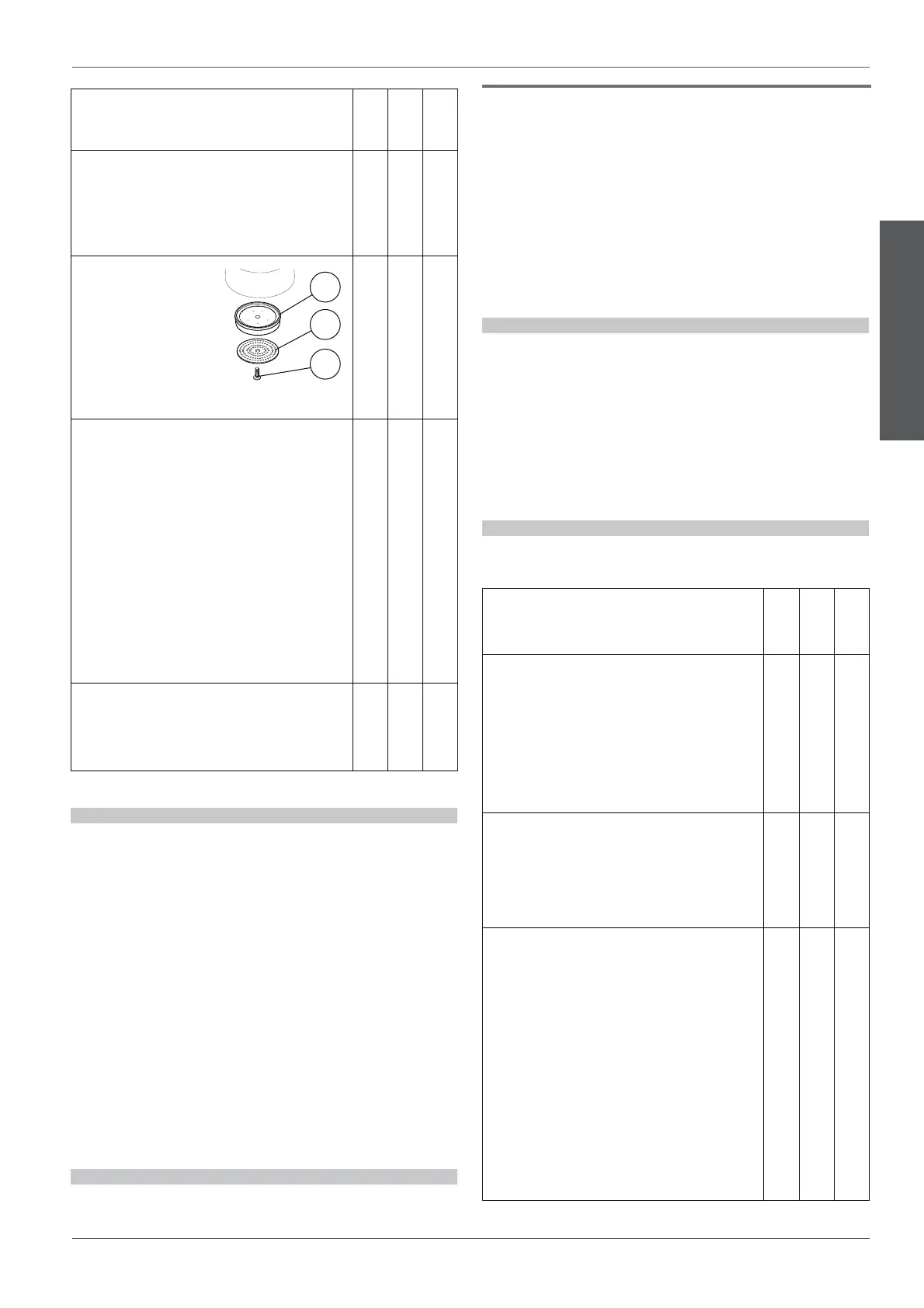

PERFORATED DISK and

CONTAINMENT RING

Loosen the screw (A) and

remove the perforated

disk (B) and containment

ring (C) from the delivery group.

Wash with hot water.

X

DISPENSING UNIT

Carry out the washing of the groups as indicated in

Chapter 21 and follow the instructions below:

t use the blind lter holder;

t pour the detergent on the solid lter and attach

the lter holder;

t carry out a series of deliveries until the water

comes out clean;

t remove the lter holder from the unit and carry

out at least one delivery so as to eliminate any

detergent residues.

X

GRINDER-DOSER

Clean the inside and outside of the receptacle and

doser of the grinder-doser with a cloth dampened

in lukewarm water.

X

C

B

A

23 Checks and maintenance

23.1 Control and maintenance operations

To ensure perfect safety and eciency of the machine

over time, it is necessary to carry out maintenance. In

particular, it is advisable to carry out an overall check

of the machine at least once a year.

!

t During the cleaning operations, pay attention

to the parts of the machine that are overheated.

t To guarantee the correct operation and hygiene

of the machine, it is necessary to use the

cleaning methods and products suitable for

the purpose.

t Do not immerge the machine into water.

t Never use alkaline detergents, solvents, alcohol

or aggressive substances.

t The descaling of the machine has to be

performed by dismounting the encrusted

components, so that no descaling debris is put

into circulation. The used products/detergents

have to be suitable for the purpose and must

not corrode the hydraulic circuits materials.

Checks

Weekly

Monthly

Yearly

MACHINE

t Using the machine display, check that the indicated

pump pressure is around 8-9 bar.

t Check that the boiler pressure indicated on the

display is consistent with a programming value.

X

FILTER HOLDER FILTERS

Check the wear of the lters, if there is damage to

the edges, and if coee grounds are getting into the

cup. If necessary, replace the lters.

X

GRINDER-DOSER

t Check the dose of the ground coee, which should

be about 6-7 gr. at a time, and adjust the amount

as necessary.

t Check the degree of grinding and modify as

required.

t Check the grinders for wear: they should be re-

placed if there is too much powder in the ground

coee.

t You should replace the at grinders after every

400/500 kg of coee. For conical grinders, replace

every 800/900 kg

X

!

Not After maintenance and/or repair intervention,

the components used must ensure that the hygiene

and safety requirements initially provided for

the appliance are still met. These are met by

using original spare parts only. After repair or

replacement of components related to parts in

direct contact with water and food, a washing

procedure has to be carried out, as in the case of

rst installation.

Loading...

Loading...