上海维宏电子科技股份有限公司

Weihong Electronic Technology Co., Ltd.

Specialized, Concentrated, Focused - 95 -

―AREAMAX-1‖, then Z2 axis will be activated.

In alternative mode, machine will execute the following actions if T command is met.

1) Z1 axis stops;

2) Z1 axis raise to the position ―AREAMAX-1‖;

3) Z1 axis is disabled;

4) Z2 axis is enabled and selected.

Note:

In linkage mode, at least one Z axis is activated, while in alternative mode, only (at most) one Z axis can be

activated.

4.1.2 Tool Measurement

In Dual Z-axes system, tool measurement can be divided into first calibration/calibration after tool

change (―Second calibration‖ on the screen), set Z1Z2 tool length (also known as fixed calibration) and

mobile calibration.

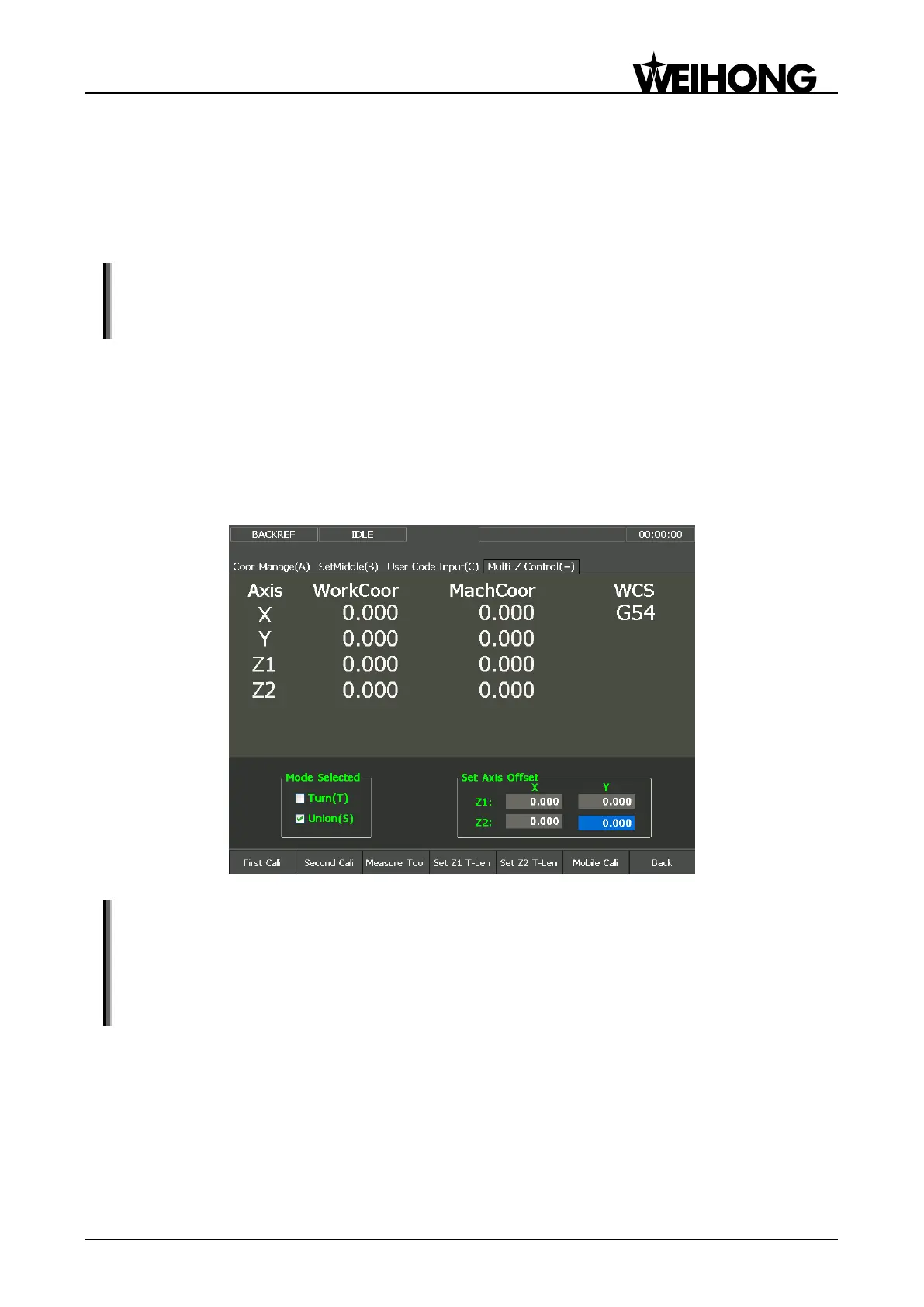

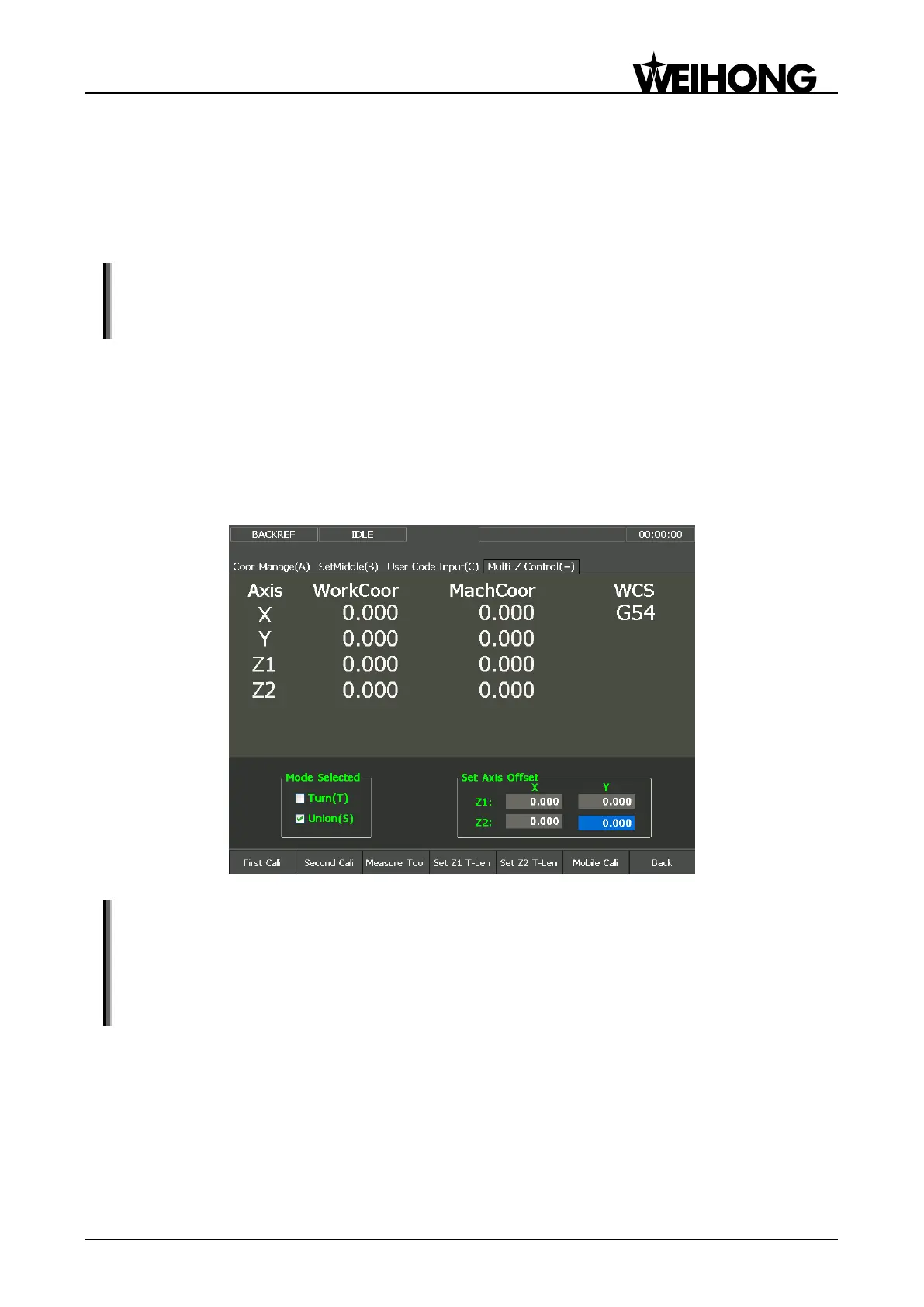

On the sub-screen [Multi-Z Control(=)] under [Coor] function area , press F4 [Tool cali] to enter tool

measurement screen. Specific operational steps are similar to the introduction in chapter 3.6. You can

turn to chapter 3.6 for details.

Fig. 4-2 Multiple Z axes control---Tool measurement

Note:

If both Z1 and Z2 axes are active, when tool measurement is being executed:

1) With dual tool presetter, two Z axes will raise to the position ―AREAMAX-1‖, and then execute tool calibration.

2) With only one tool presetter, two Z axes will raise to the position ―AREAMAX-1‖, then Z1 axis will execute tool

calibration first. Tool calibration in Z2 axis will be executed after calibration in Z1 axis is finished.

4.2 Special Parameters

For dual Z axes system and standard four axes system, most parameters share the same

parameter name while their parameter number may be different. The following parameters are those

specifically exist in dual Z axes. And for those in common, please refer to chapter 7 to view all

parameters in standard four axes system.

Loading...

Loading...