上海维宏电子科技股份有限公司

Weihong Electronic Technology Co., Ltd.

Specialized, Concentrated, Focused - 47 -

presetter position in fixed calibration

Positive Travel Limit (MCS)

Y coordinate of fixed cali

block

Z coordinate of fixed cali

block

The measurement method for parameter ―Cali Block Thickness‖ is as below:

Manually move the Z-axis to a certain point over the workbench surface→ shift down its tool

nose until reaching the surface of workbench→ the system will record current coordinate Z1 of

Z-axis.

Uplift Z-axis→ put the tool presetter on the workbench surface→ shift down Z-axis slowly until

reaching the tool presetter and getting the presetter signal→ the system will record the current

coordinate Z2 of Z axis

Subtract Z1 from Z2, and the result equals to the thickness of tool presetter in fixed calibration.

Manually enter this value into this parameter.

3.6.4 First Calibration/ Tool Calibration after Tool Change

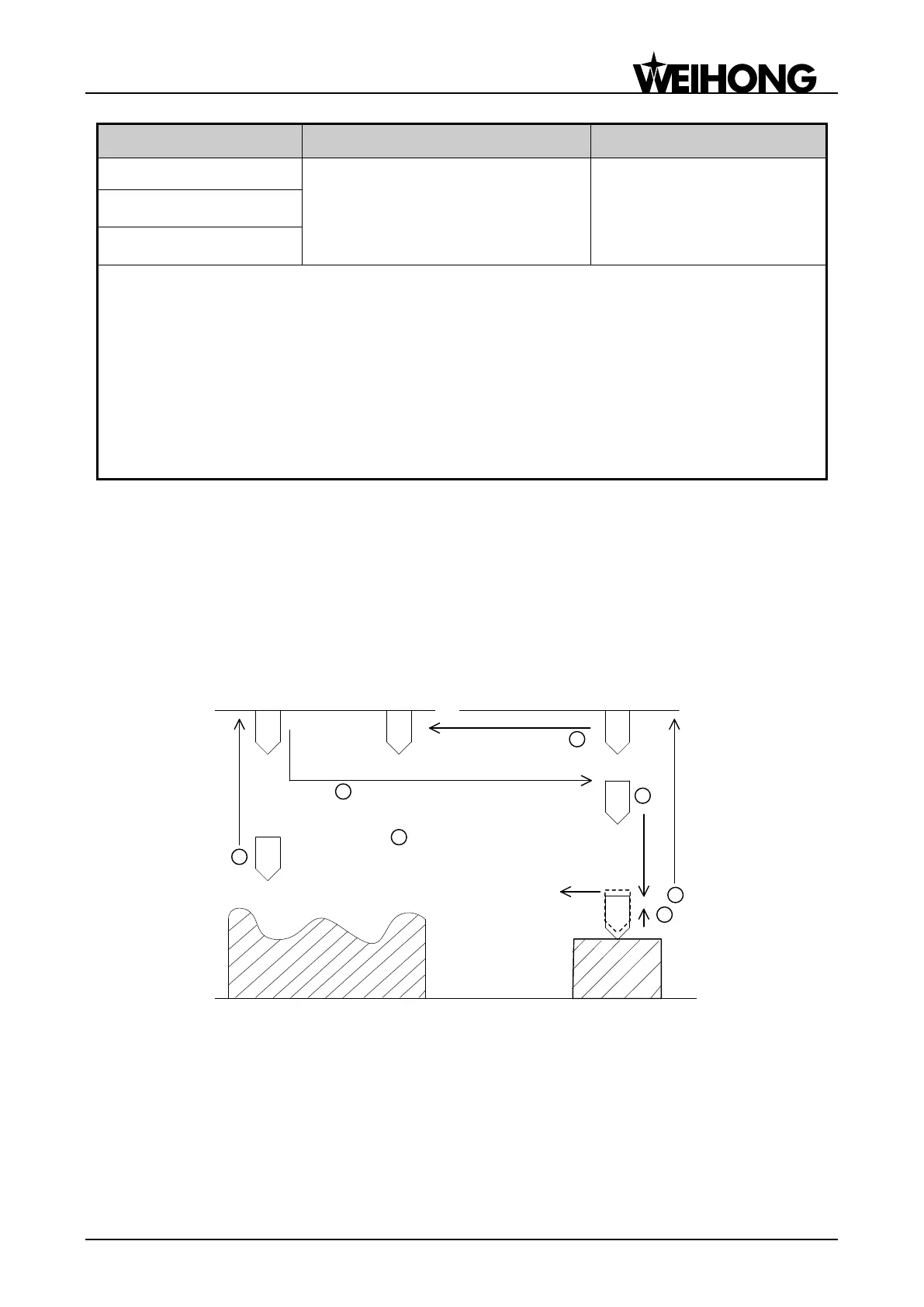

The operation steps are as below:

Firstly, manually move Z axis to workpiece surface, and then confirm the workpiece origin by mobile

calibration or manual clear (the method for manual clear: press F6 [Clear], and then press F4 [Z

Clear] in the new pop-up manipulation button bar).

Secondly, press F5 [Preset], and then press F1 [First Time] to execute the first calibration in the new

pop-up manipulation button bar, and the system will record the current machine coordinate value of

Z axis automatically, as shown in Fig. 3-20. The system ends this process automatically.

Record current Z axis

machine coordinate

Top

3

4

Up 1mm

To tool

presetter

5

Up to the top of Z axis

6

Back to upper side of

workpiece origin

2

To machine coordinate of tool presetter

Up to the top of Z axis

1

Workpiece Origin

Fig. 3-20 First calibration

The first calibration finishes and workpiece machining begins.

After tool change or tool break, press F5 [Preset], and then press F2 [After Tool Change] in the new

pop-up manipulation button bar to restore the Z workpiece coordinate value of current point, as

shown in Fig. 3-21. The system ends this process automatically.

Loading...

Loading...