PROCEDURE

1 Isolate the defective cylinder from the cooling water system.

2 Make sure that there is no air spring air pressure.

3 Lock the exhaust valve in the open position as follows:

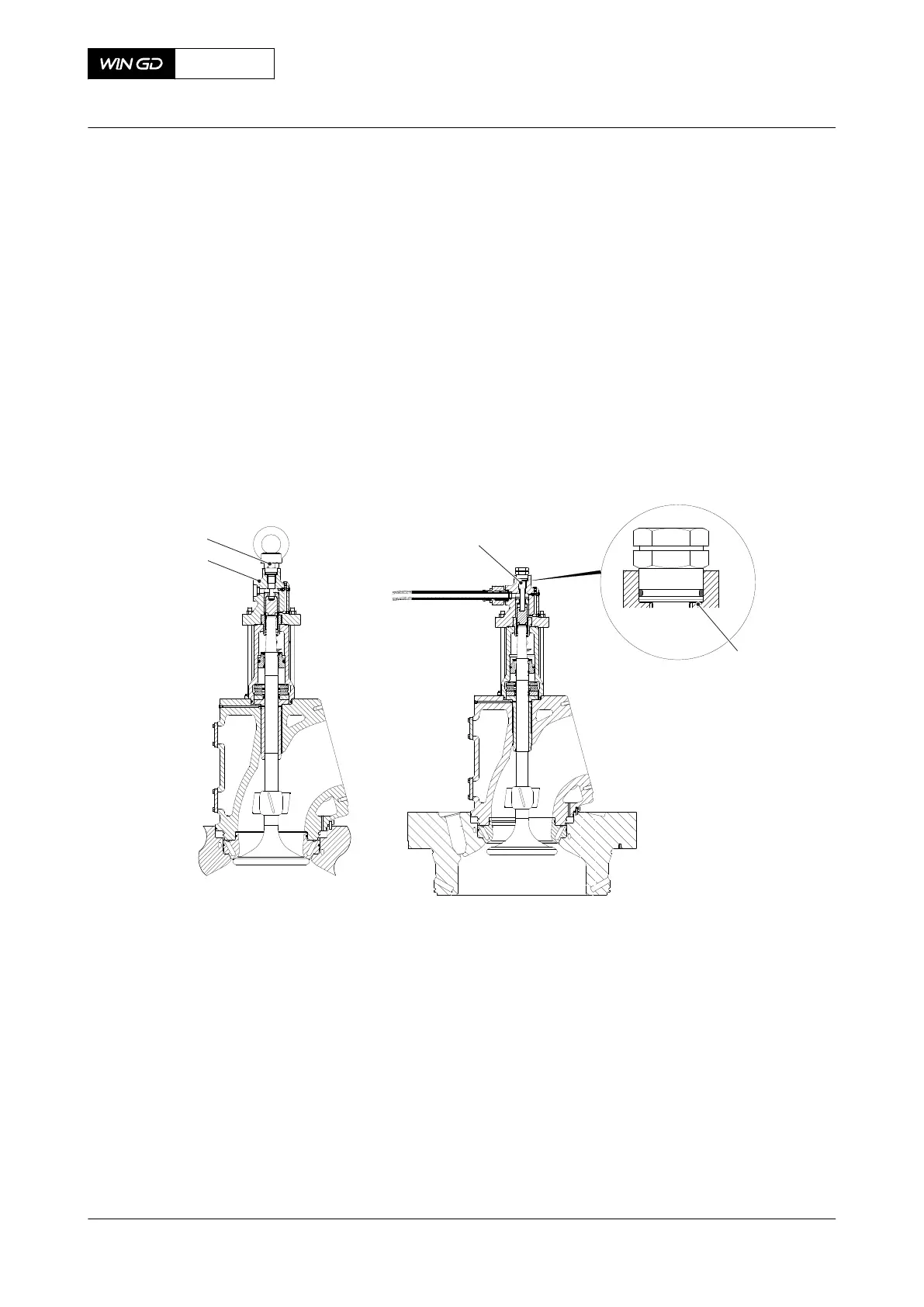

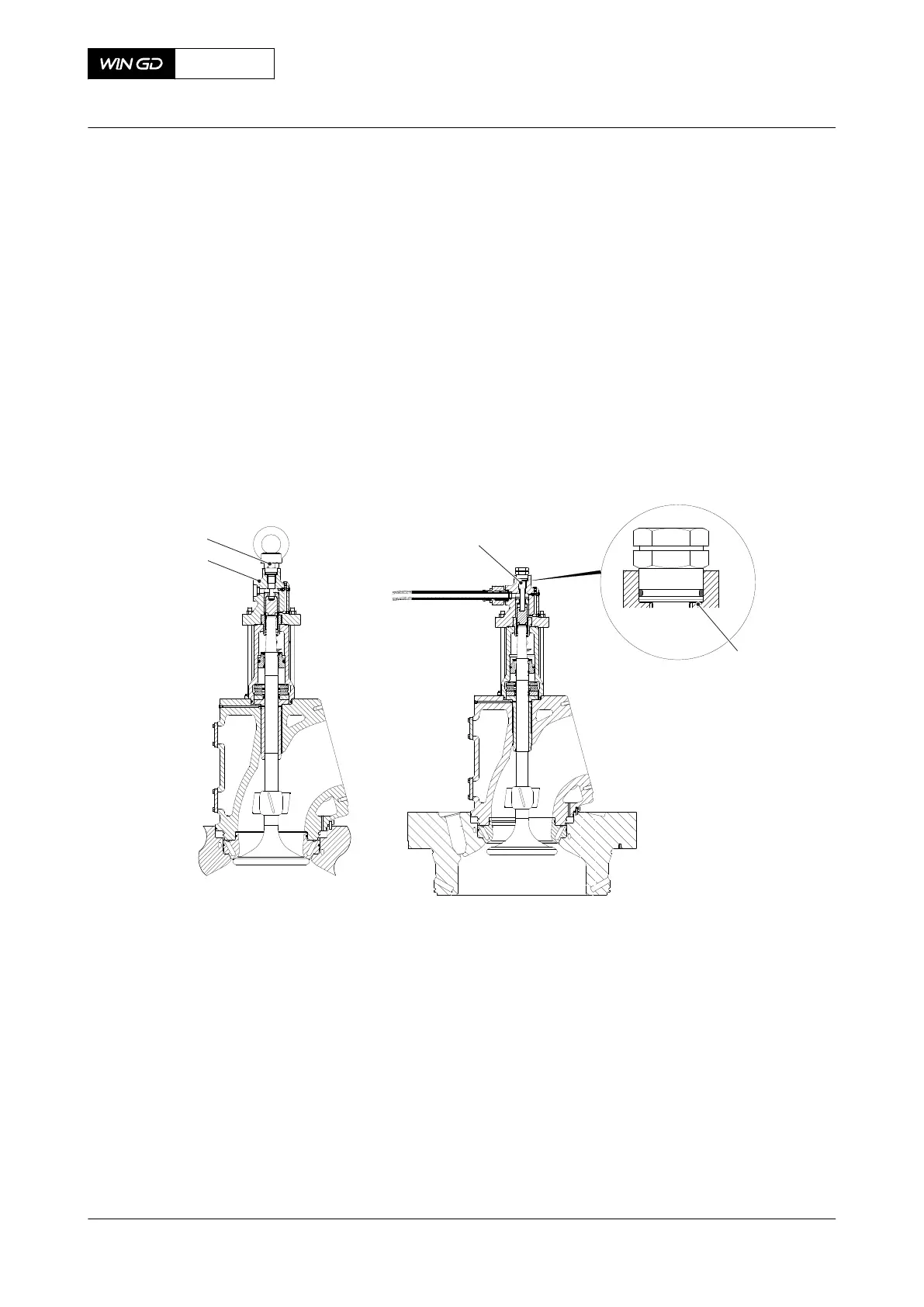

3.1 Remove the damper (002, Figure 10-5) from the top housing (001).

3.2 Make sure that you do not lose the shim(s) (004).

NOTE: The shim(s) must stay in position when the pressure element is

installed.

3.3 Apply a thin layer of oil to the thread of the pressure element (003).

3.4 Install the pressure element (003).

Fig 10-5 Exhaust valve with pressure element

Legend

001 Top housing 003 Pressure element

002 Damper 004 Shim

4 Cut out the defective cylinder from the injection, refer to section 10.7 Temporary cut out

a defective injection valve.

5 Disconnect the electrical connection to the related exhaust valve control unit (VCU).

6 Disconnect the control signal connection from the related starting air valve.

7 Repair the fault as soon as possible, refer to the Maintenance Manual.

X92DF

AA00-0000-00AAA-662B-A

Operation Manual Temporary isolate a cylinder with cooling water leakage

Winterthur Gas & Diesel Ltd.

- 551 - Issue 002 2020-08

Loading...

Loading...