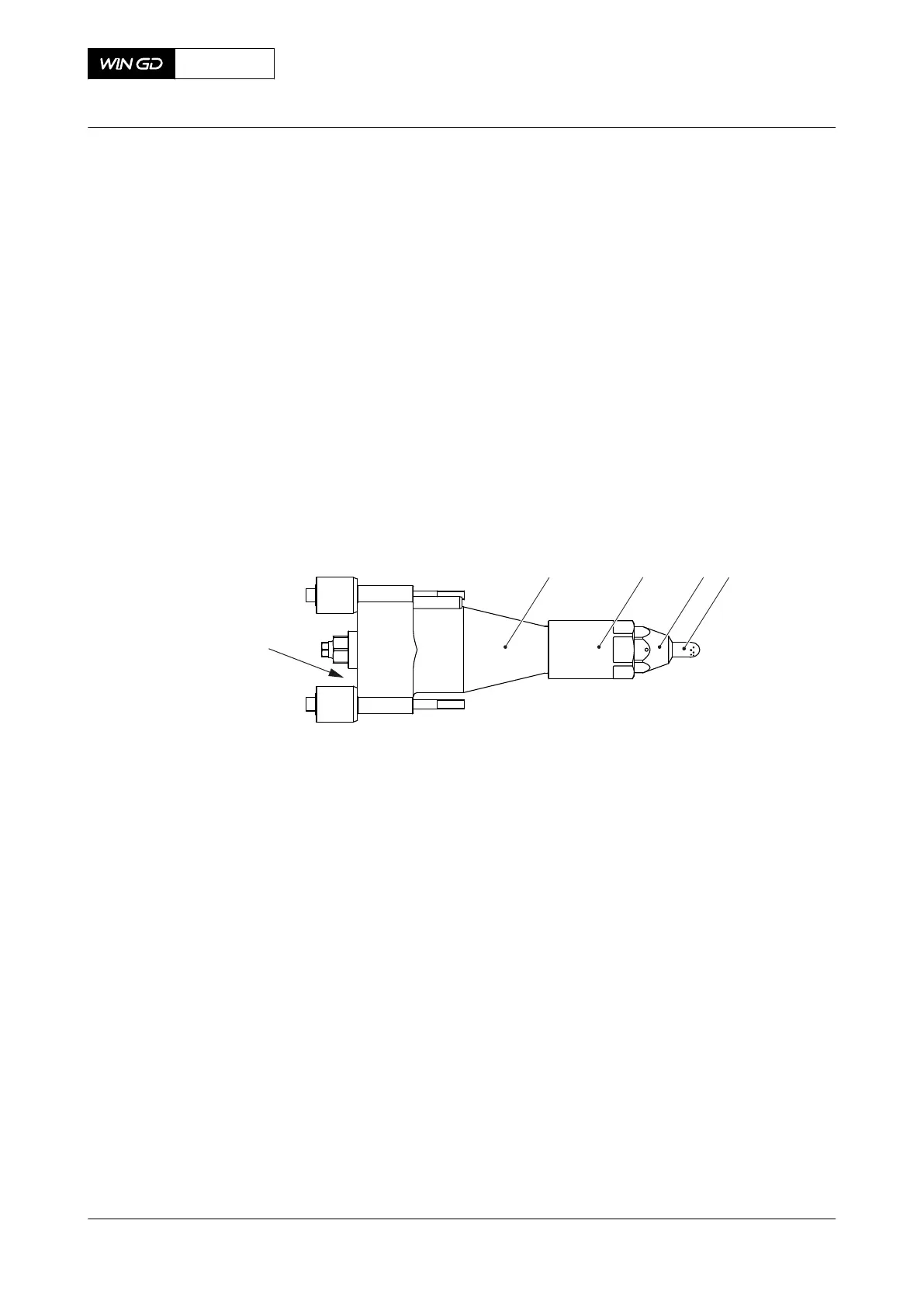

5.2.5 Conventional injection valve

The injection valves are installed in the cylinder cover of each cylinder. The injection valves

spray the fuel into the combustion chamber. The injection control unit (ICU) controls the timing

and the quantity of the injected fuel related to the power.

The high pressure of the supplied fuel from the ICU opens the needle in the nozzle body. This

lets the fuel flow through the holes in the nozzle tip (004, Figure 5-11) into the combustion

chamber as a spray. When the pressure from the ICU decreases, a spring closes the needle

again.

The nozzle usually has the Fuel Actuated Sacless Technology (FAST) for better combustion

properties.

A small quantity of fuel flows through the inner part of the valve to lubricate the needle. This fuel

then flows through the return pipe back to the plant fuel system.

Fig 5-11 Injection valve (example)

Legend

001 Nozzle holder 004 Nozzle tip

002 Coupling nut 005 Fuel inlet

003 Clamping nut

X92DF

AA00-2722-00AAA-043B-A

Operation Manual Conventional injection valve

Winterthur Gas & Diesel Ltd.

- 166 - Issue 002 2020-08

Loading...

Loading...