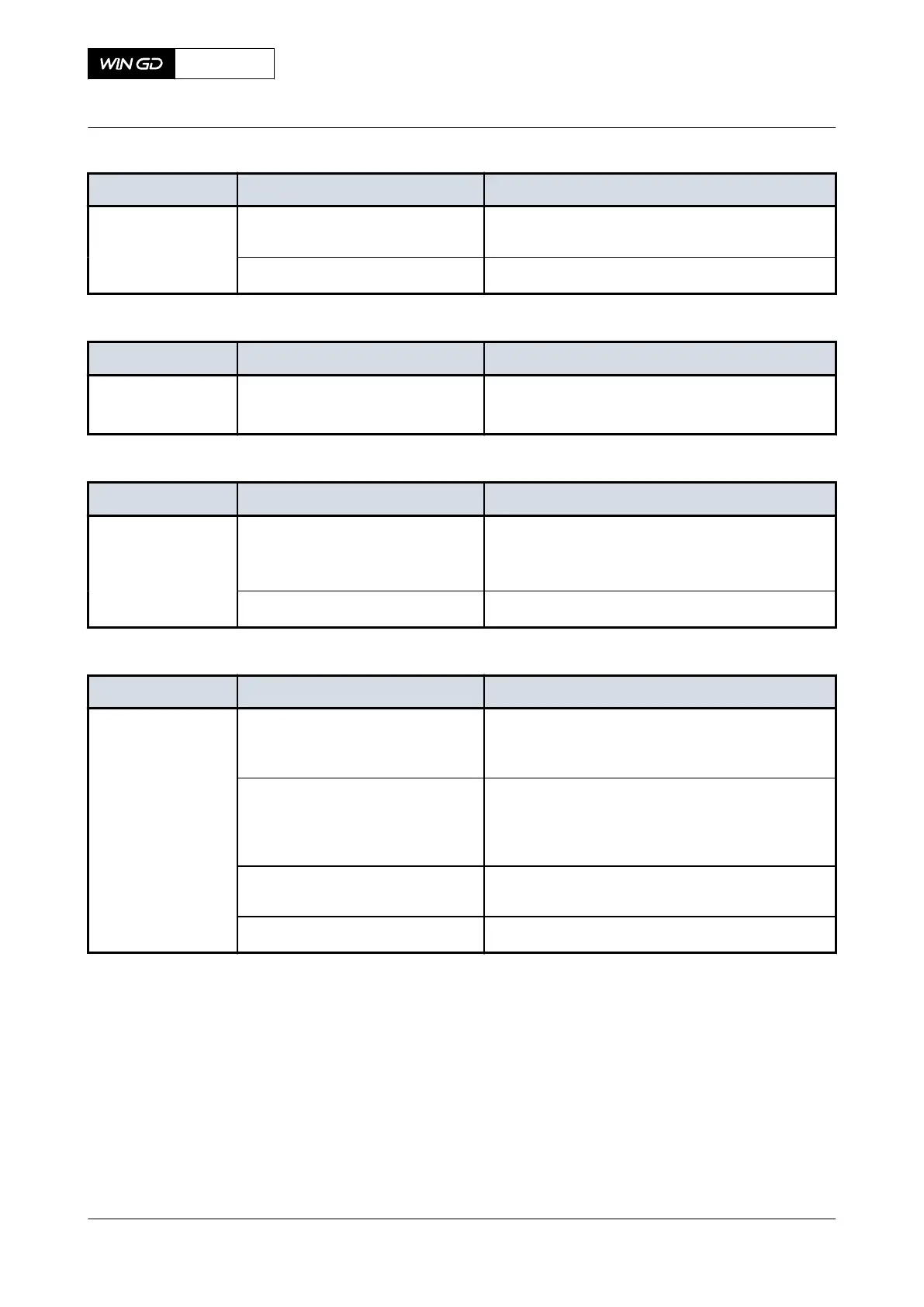

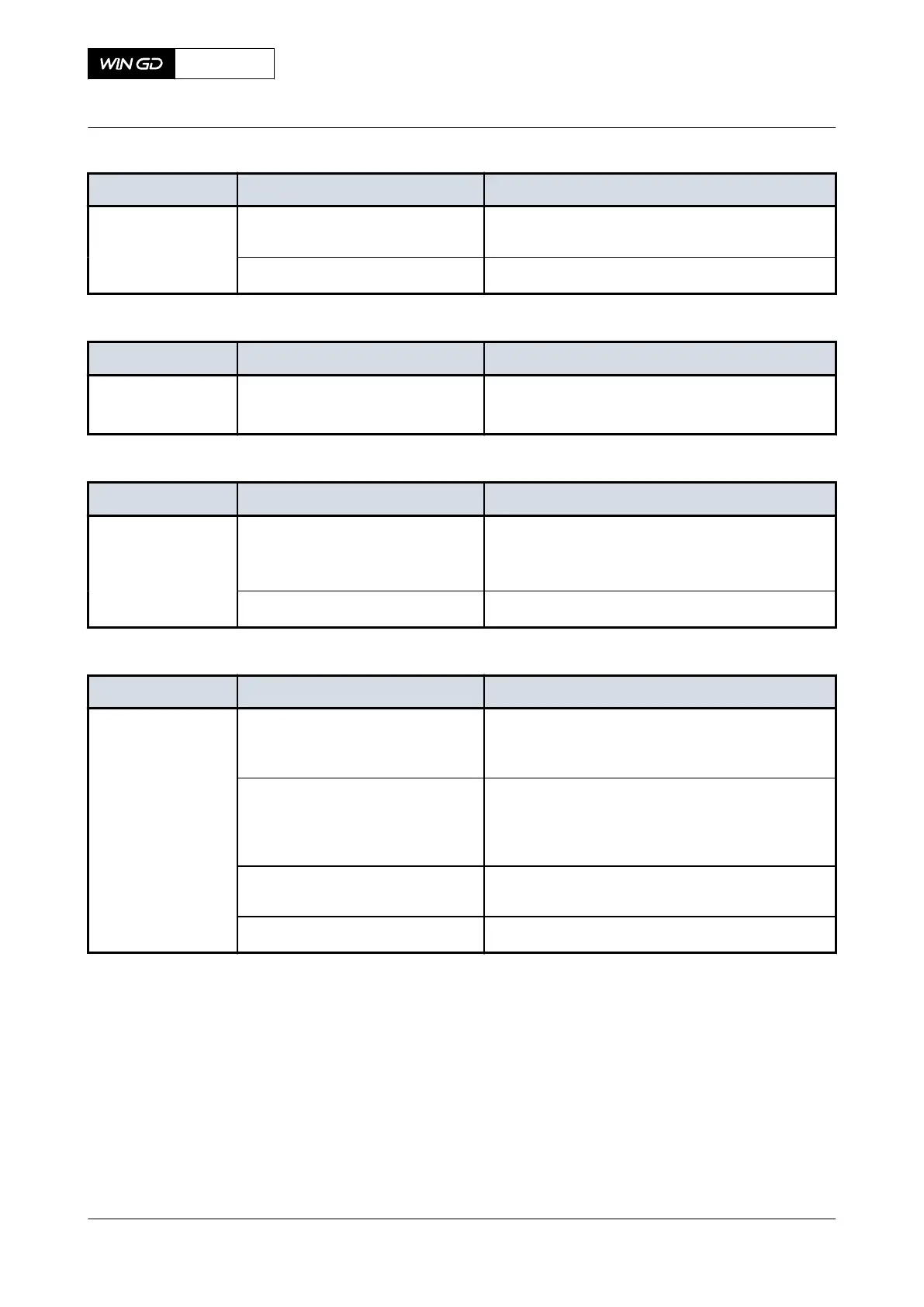

Tab 10-21 Damper oil supply pressure upstream of the torsional vibration damper is too low

Indication Possible cause Procedure

PT2711A There is an incorrect setting of the

throttle valve

•

Set the throttle valve to the correct value.

An oil supply pipe is defective

•

Replace the oil supply pipe.

Tab 10-22 Damper oil supply pressure upstream of the axial vibration damper is too low

Indication Possible cause Procedure

PT2721A

PT2722A

A sealing ring is defective

•

Replace the defective sealing ring.

Tab 10-23 Cylinder oil supply pressure is too low

Indication Possible cause Procedure

PT3124A A filter element is clogged

•

Change over to the other filter chamber.

•

Replace or clean the clogged filter ele-

ment.

The cylinder oil tank is empty

•

Fill the cylinder oil tank.

Tab 10-24 Cylinder oil flow is too low

Indication Possible cause Procedure

This is a result of the malfunction

in Table 10-23 - Cylinder oil sup-

ply pressure is too low

•

Do the repair shown there.

This is a result of the malfunction

in Table 10-11 - Servo oil pressure

in the distributor pipe (mini rail) is

not in the permitted range

•

Do the repair shown there.

There is air in the cylinder oil sys-

tem

•

Release the unwanted air from the cylinder

oil system.

Lubricating quills are blocked

•

Clean or replace defective parts.

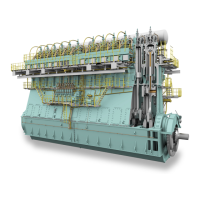

X92DF

AA00-0000-00AAA-410C-A

Operation Manual Malfunctions of systems and components

Winterthur Gas & Diesel Ltd.

- 520 - Issue 002 2020-08

Loading...

Loading...