General Procedures and Information

Phaser 3100 MFP 04/08 6-59

Printing

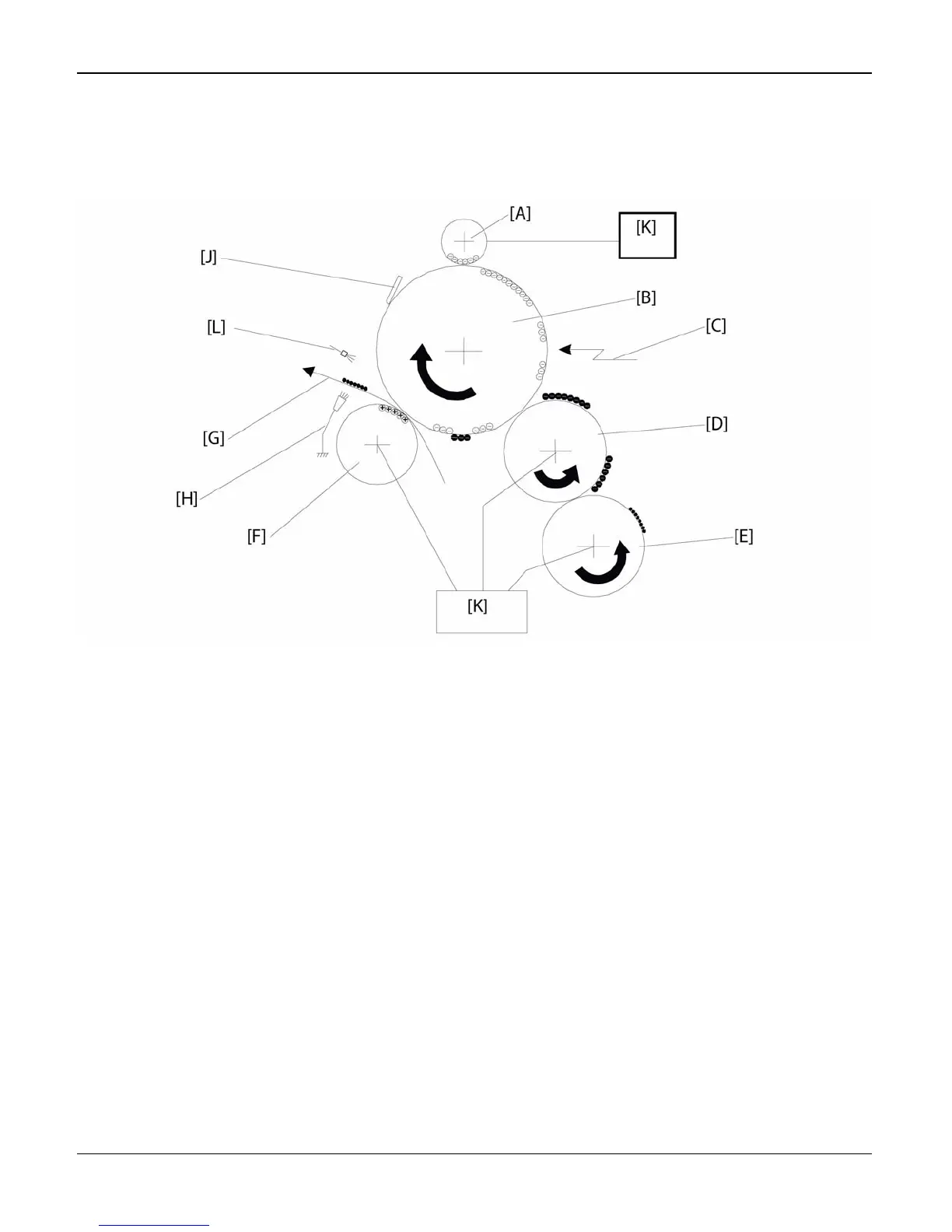

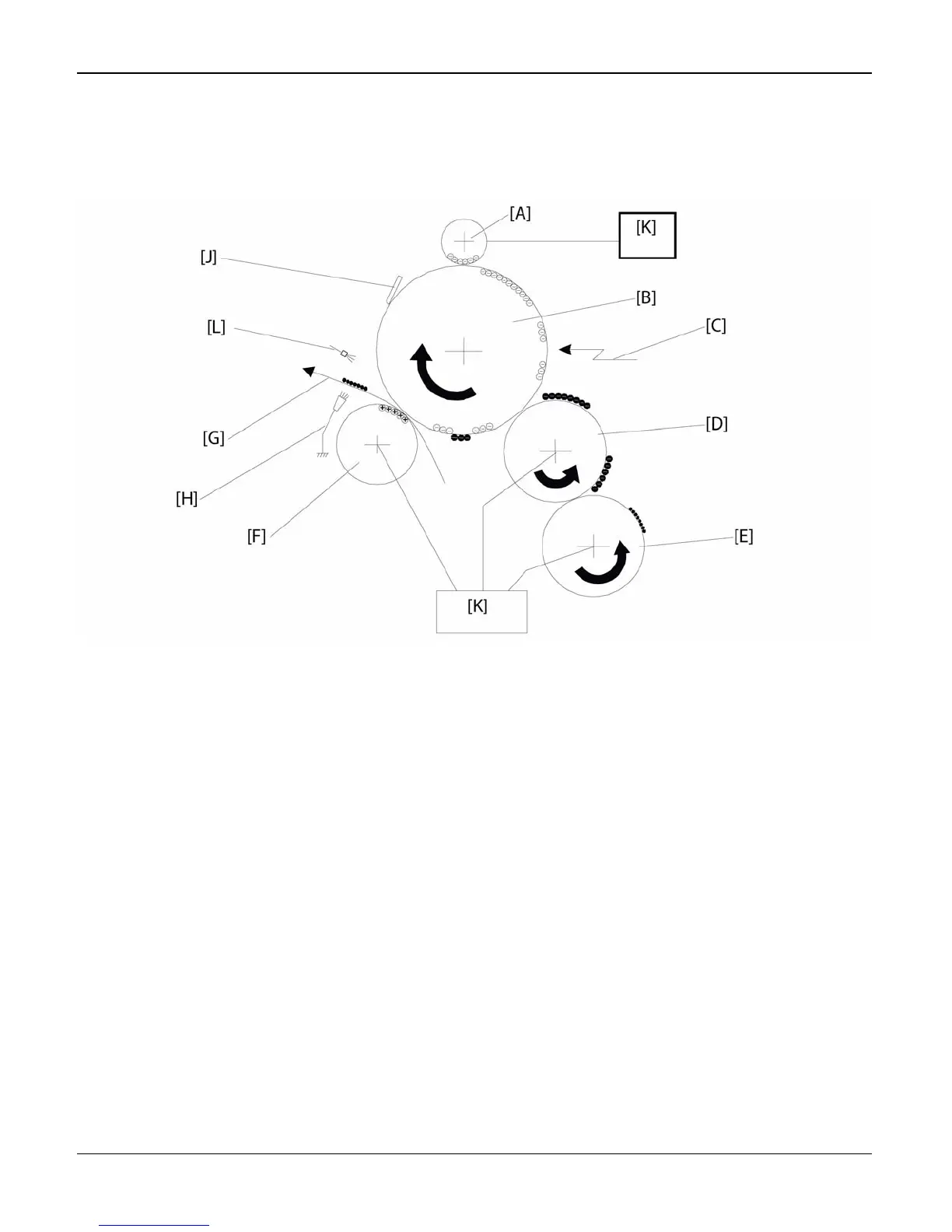

Printing Processes Around the Drum

Figure 2

This machine uses a “write to black” system, using negative toner.

Charge: The charge brush roller [A] gives the OPC drum [B] surface a negative charge.

Exposure: A laser [C] writes a latent image on the drum. The charge in the area exposed by the

laser beam drops.

Development: The development roller [D] carries toner to the drum and develops the latent image

on the drum. The following charges are applied. Development bias (during printing): Toner appli-

cation roller [E] Development roller [D] Switching bias (At the start and the end of any print proc-

ess): Toner application roller [E] Development roller [D]

Image Transfer: The transfer roller [F] pulls the toner from the drum onto the paper [G].

Paper Separation: The antistatic brush [H] removes the charge on the underside of the paper to

help the paper separate from the drum.

Drum Cleaning: The Discharge Lamp[L] discharge the OPC drum [B] surface, The cleaning blade

[J] removes any toner remaining on the drum after the image is transferred to paper.

The high voltages [K] are supplied from the Power Supply Unit board.

Loading...

Loading...