January 2016

2-37

WorkCentre 4150/4250/4260WorkCentre WorkCentre 4150/4250/42604150/

05-900

Status Indicator RAPs

05-900 DADF Jam 0 RAP

05-900 The lead edge of the document failed to actuate the registration sensor within the cor-

rect time.

Procedure

WARNING

Switch off the electricity to the machine. Disconnect the power cord from the customer

supply while performing tasks that do not need electricity. Electricity can cause death or

injury. Moving parts can cause injury.

Go to the relevant procedure:

• 4150 Checkout

• 4250/4260 Checkout

• 4265 Checkout

4150 Checkout

Refer to Wiring Diagram 11. Perform the following:

1. Remove all jammed paper from the DADF input tray.

2. Open the DADF top cover assembly, PL 5.15 Item 11. Check the document path for dam-

age or obstructions.

3. Check the feed roll assembly, PL 5.15 Item 5. If necessary, install a new feed roll assem-

bly, PL 5.15 Item 5.

4. Check the retard pad, PL 5.20 Item 12. If necessary, install a new retard pad, PL 5.20

Item 12.

5. Check that the registration sensor actuator, PL 5.15 Item 12 moves freely and is not dam-

aged.

6. Enter dC330 code 05-130. Check the registration sensor (Q05-130), PL 5.15 Item 14.

7. Check the wiring between the registration sensor and CN5 on the DADF Sensor PWB. If

necessary, install a new registration sensor, PL 5.15 Item 14.

8. Check the wiring between CN1 on the DADF Sensor PWB and CN3 on the DADF PWB.

9. Enter dC330 code 05-200. Check that the DADF scan motor (MOT05-200), PL 5.25 Item

12 runs.

10. While the DADF scan motor runs, stack the code 05-300 to energize the pick up clutch

(CL05-300). Check that the feed roll, PL 5.15 Item 5 rotates.

11. Check the wiring between the pick up clutch and CN6 on the DADF PWB. If necessary,

install a new pick up clutch, PL 5.15 Item 4.

12. Check the wiring between the DADF scan motor and CN4 on the DADF PWB.

13. If necessary, install new components:

• DADF PWB, PL 5.20 Item 6.

• DADF sensor PWB, PL 5.20 Item 4.

• DADF scan motor, PL 5.25 Item 12.

• DADF scan motor assembly, PL 5.25 Item 10.

• Document transport assembly, PL 5.10 Item 2.

4250/4260 Checkout

Refer to Wiring Diagram 29. Perform the following:

1. Remove all jammed paper from the DADF input tray.

2. Open the DADF top cover assembly, PL 5.30 Item 2. Check the document path for dam-

age or obstructions.

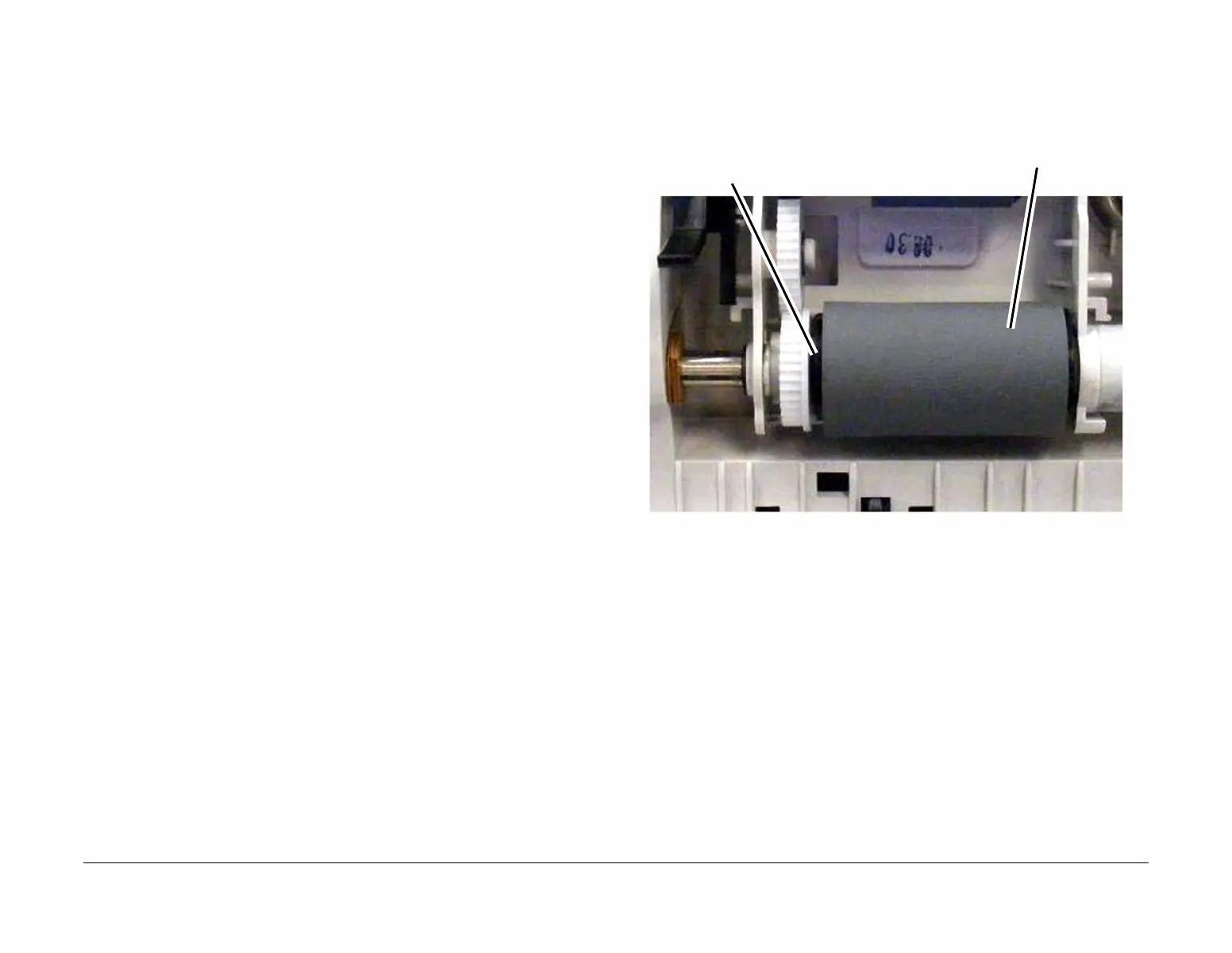

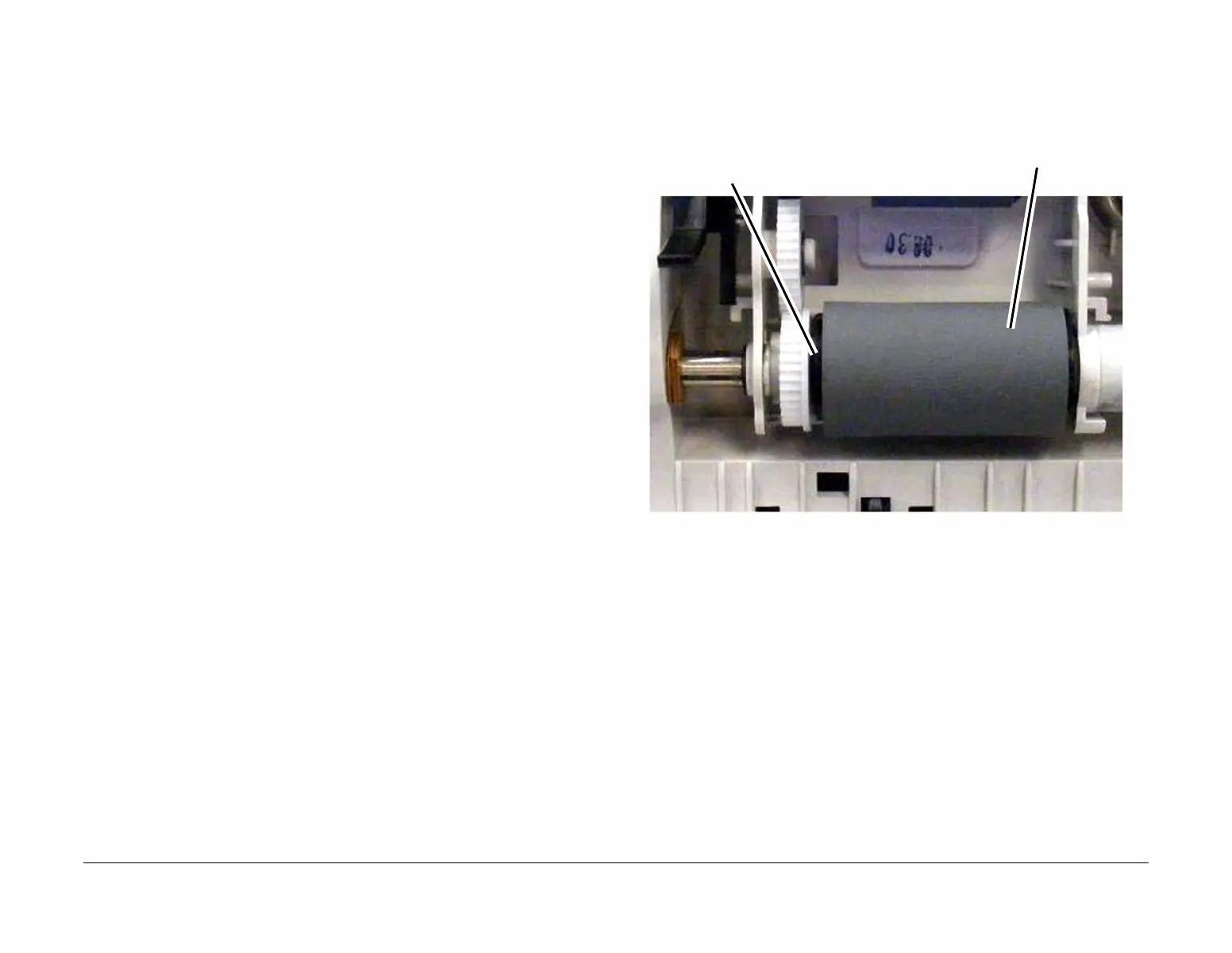

3. Check the feed roll assembly, PL 5.40 Item 7 (Figure 1). If necessary, install a new feed

roll assembly, PL 5.40 Item 7.

Figure 1 Checking the Feed Roll Sleeve Position

4. Check the retard pad, PL 5.45 Item 4. If necessary, install a new retard pad, PL 5.45 Item

4.

5. Check that the registration sensor actuator, PL 5.40 Item 18 moves freely and is not dam-

aged.

6. Enter dC330 code 05-130. Check the registration sensor (Q05-130), PL 5.40 Item 17.

7. Check the wiring between the registration sensor and CN7 on the DADF PWB. If neces-

sary, install a new registration sensor, PL 5.40 Item 17.

8. Enter dC330 code 05-200. Check that the DADF scan motor (MOT05-200), PL 5.30 Item

6 runs.

9. While the DADF scan motor runs, stack the code 05-300 to energize the pick up clutch

(CL05-300). Check that the feed roll, PL 5.40 Item 7 rotates.

10. Check the wiring between the DADF scan motor and CN6 on the DADF PWB.

1

Ensure that the Feed Roll Sleeve is positioned as

shown, with a gap between the sleeve and gear.

Feed Roll Sleeve

NOTE: If the Feed Roll Sleeve is positioned against

the Gear, it will cause the Nudger Roll to stay in the

down position after feeding a document. This will

cause a false misfeed.

Loading...

Loading...