Parameter Details

12

12.2 A: Initialization Parameters

YASKAWA SIEPC71061753C GA500 Technical Manual 497

Table 12.22 Adjustment of Drive Control (Open Loop Vector Control Method)

Adjustment description Parameter Number Possible Solutions Default Recommended Setting

• Torque, increase speed

response

• Prevent hunting and

oscillation at middle-range

speeds (10 Hz to 40 Hz)

n2-01 [Automatic Freq Regulator

Gain]

• If torque and speed response

are slow, decrease the setting

value.

• If there is hunting or

oscillation, increase the setting

value.

1.00 0.50 - 2.00

• Torque, increase speed

response

• Prevent hunting and

oscillation

C4-02 [Torque Compensation

Delay Time]

*1

• If torque and speed response

are slow, decrease the setting

value.

• If there is hunting or

oscillation, increase the setting

value.

20 ms 20 ms to 100 ms

• Increase speed response

• Increase speed stability

C3-02 [Slip Compensation Delay

Time]

• When speed response is slow,

decrease the setting value.

• If speed is not stable, increase

the setting value.

200 ms 100 ms to 500 ms

• Improve speed accuracy C3-01 [Slip Compensation Gain]

• If speed is too slow, increase

the setting value.

• If speed is too fast, decrease

the setting value.

1.0 0.5 - 1.5

• Increasing motor excitation

sound

• Prevent hunting and

oscillation at low-range speeds

(10 Hz to or lower)

C6-02 [Carrier Frequency

Selection]

• If there is a loud motor

excitation sound, increase the

setting value.

• If there is hunting or

oscillation at low speeds,

decrease the setting value.

*2

1 - F

• Increase torque and speed

response at low speeds

• Prevent shock during start up

E1-08 [Mid Point AVoltage]

• If the torque and speed

response are slow, increase the

setting value.

• If there is a large shock during

start up, decrease the setting

value.

11.0 V

*3

12.0 V to 13.0 V

*3

E1-10 [Minimum Output Voltage] 2.0 V

*3

2.0 V to 3.0 V

*3

*1 If the value for C4-02 [Torque Compensation Delay Time] is high, the current can increase during start up. Adjust and check the

current during start up.

*2 The default setting changes when the settings for C6-01 [Normal / Heavy Duty Selection] and o2-04 [Drive Model (KVA) Selection]

change.

*3 This is the setting for 200 V class drives. Multiply the voltage by 2 for 400 V class drives.

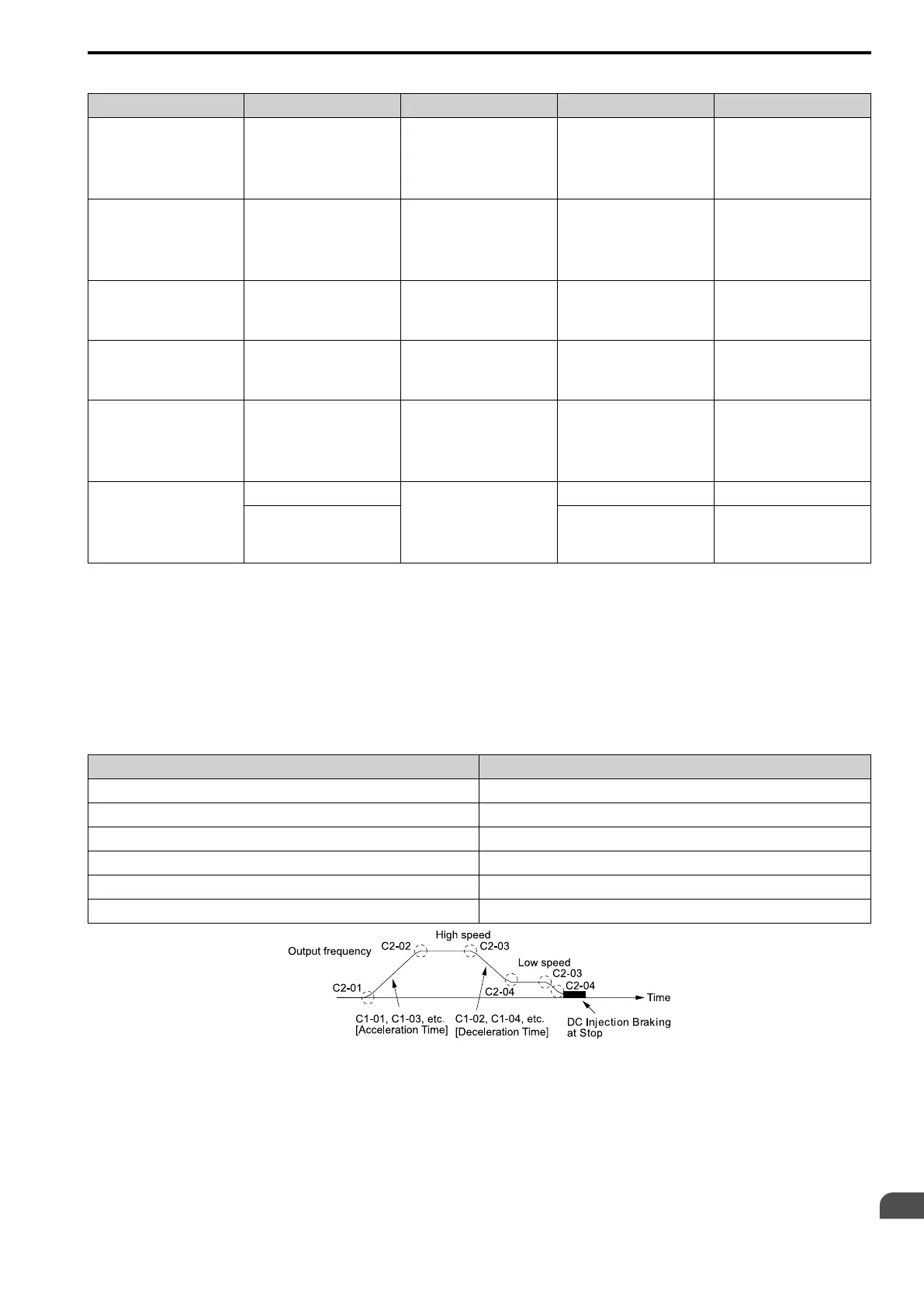

Elevator Start/Stop and Accel/Decel Time Shock Reduction

Shock when you start and stop the elevator and when you accelerate and decelerate is an issue for passenger

elevator applications. If shock has an effect on the quality of the ride, adjust these parameters:

S-Curve Characteristics, Accel & Decel Time

Adjustment Parameter Name

C1-01, C1-03, C1-05, C1-07 Acceleration Time 1 to 4

C1-02, C1-04, C1-06, C1-08 Deceleration Time 1 to 4

C2-01 S-Curve Time @ Start of Accel

C2-02 S-Curve Time @ End of Accel

C2-03 S-Curve Time @ Start of Decel

C2-04 S-Curve Time @ End of Decel

Figure 12.4 S-curve Characteristics, Accel & Decel Time

Loading...

Loading...