3.2 Operating Procedures for Utility Functions

3.2.28 Advanced Autotuning without Reference (Fn201)

3-73

3-3

Type

Select the type according to the machine element to drive. If there is

noise or if the gain does not increase, better results may be obtained by

changing the rigidity type. Select the type according to the following

guidelines.

1: Belt drive mechanisms

2: Ball screw drive mechanisms (default setting)

3: Rigid systems in which the Servomotor is directly coupled to the

machine (without gear or other drive system)

3-4

Stroke (Travel Distance)

Set the travel distance.

• Travel distance setting range: -99,990,000 to 99,990,000 reference

units

• Minimum setting increment: 1,000 reference units

•

The negative direction is for reverse rotation, and the positive direction is

for forward rotation. The travel distance from the current position is given.

• Default setting: Approx. 3 rotations

If the Servomotor’s encoder resolution is 16,777,216 (24 bits), the

stroke (travel distance) will be set to 800,000. If the default electronic

gear ratio is used (Pn20E = 64 and Pn210 = 1), then

Note: 1. Set the parameters so that the number of motor rotations is at least 0.5.

Otherwise, ERROR will be displayed and advanced autotuning will not be

possible.

2. To calculate the moment of inertia and ensure precise tuning, we recom-

mend that you set the number of motor rotations to approximately 3.

3. For an SGMCS or SGMCV Direct Drive Servomotor, the default setting for

the number of motor rotations is approximately 0.3.

4

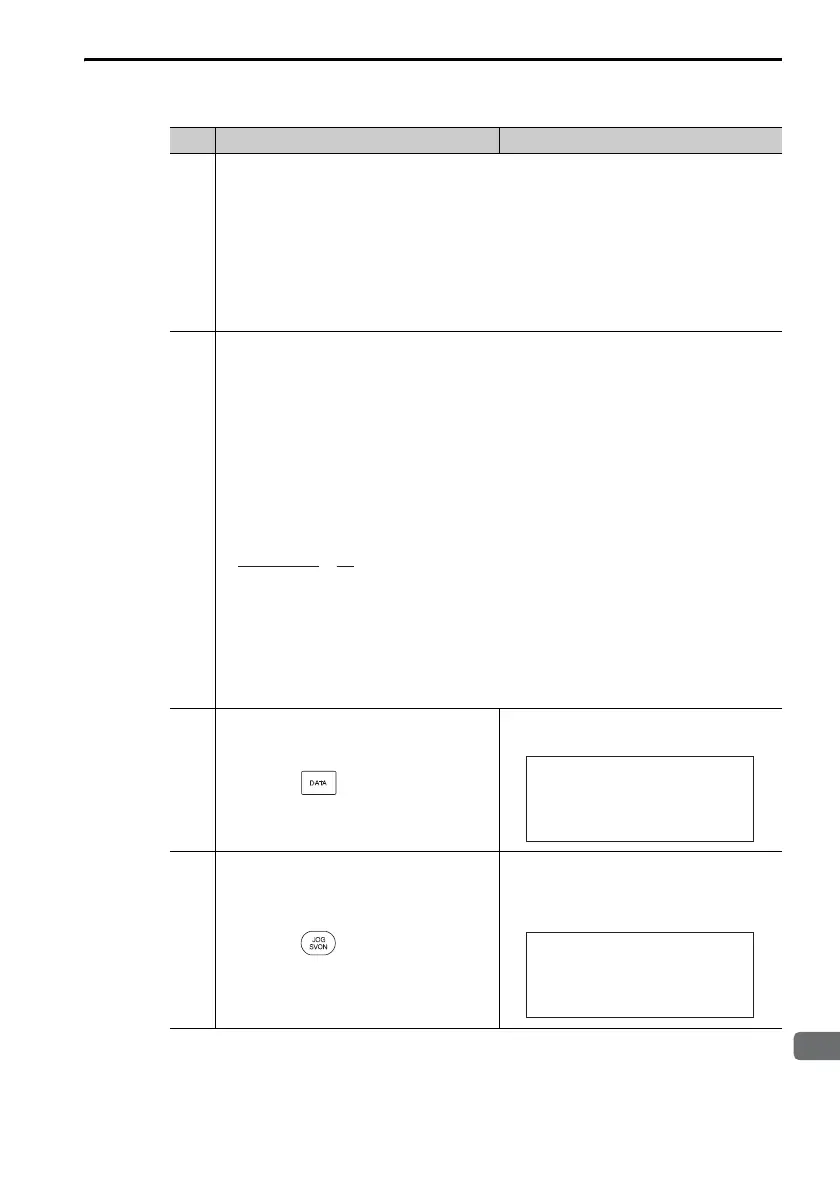

Press the Key.

The execution display for advanced

autotuning will appear.

5

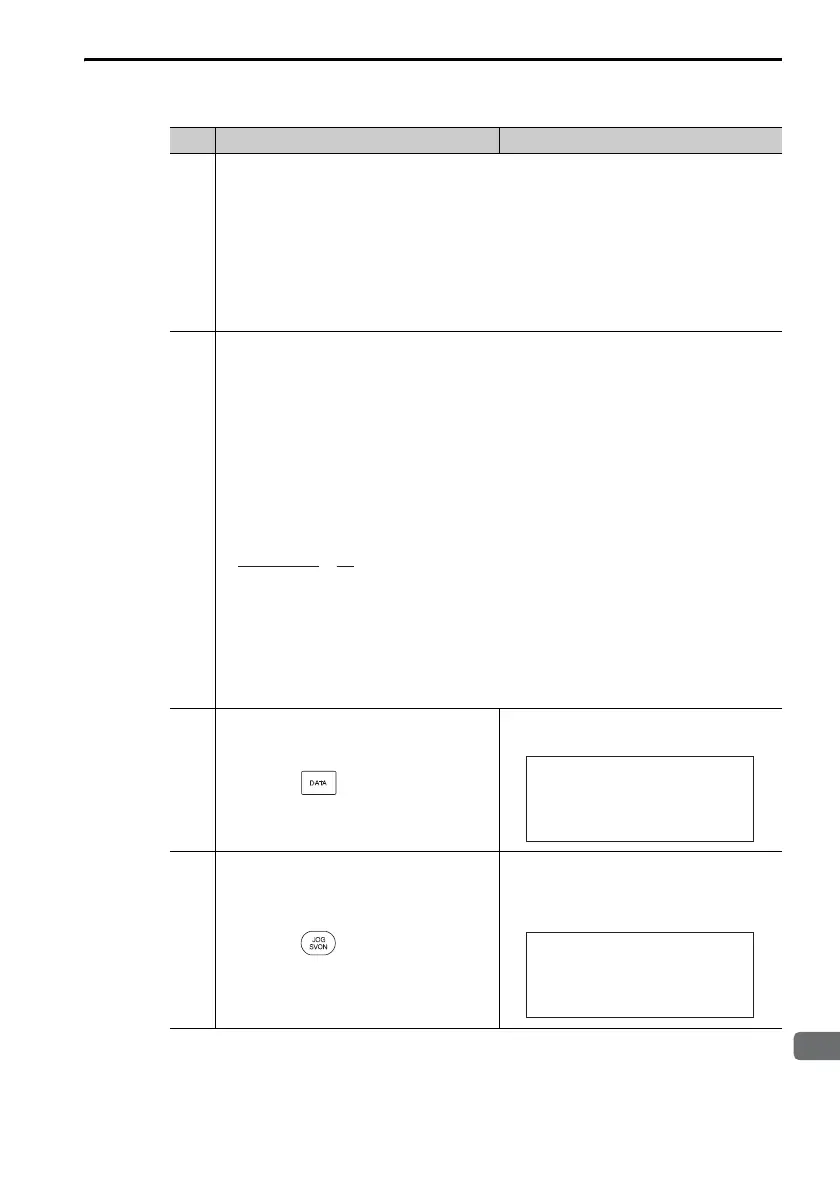

Press the Key.

The servo will be turned ON and the

display will change from

BB

to

RUN

.

Note: If the mode is set to 2 or 3, Pn141

will be displayed instead of Pn102.

Continued on next page.

Continued from previous page.

Step Operation Result

×

800,000

16,777,216

64

1

≈ 3 (revolutions)

1:BB AAT

Pn103 =00000

Pn100=0040.0

Pn101=0020.00

Pn102=0040.0

1:RUN AAT

Pn103 =00000

Pn100=0040.0

Pn101=0020.00

Pn141=0050.0

Loading...

Loading...