Parameter Details

5

5.2 b: Application

YASKAWA SIEPYAIH6B01A HV600 AC Drive Bypass Technical Reference 209

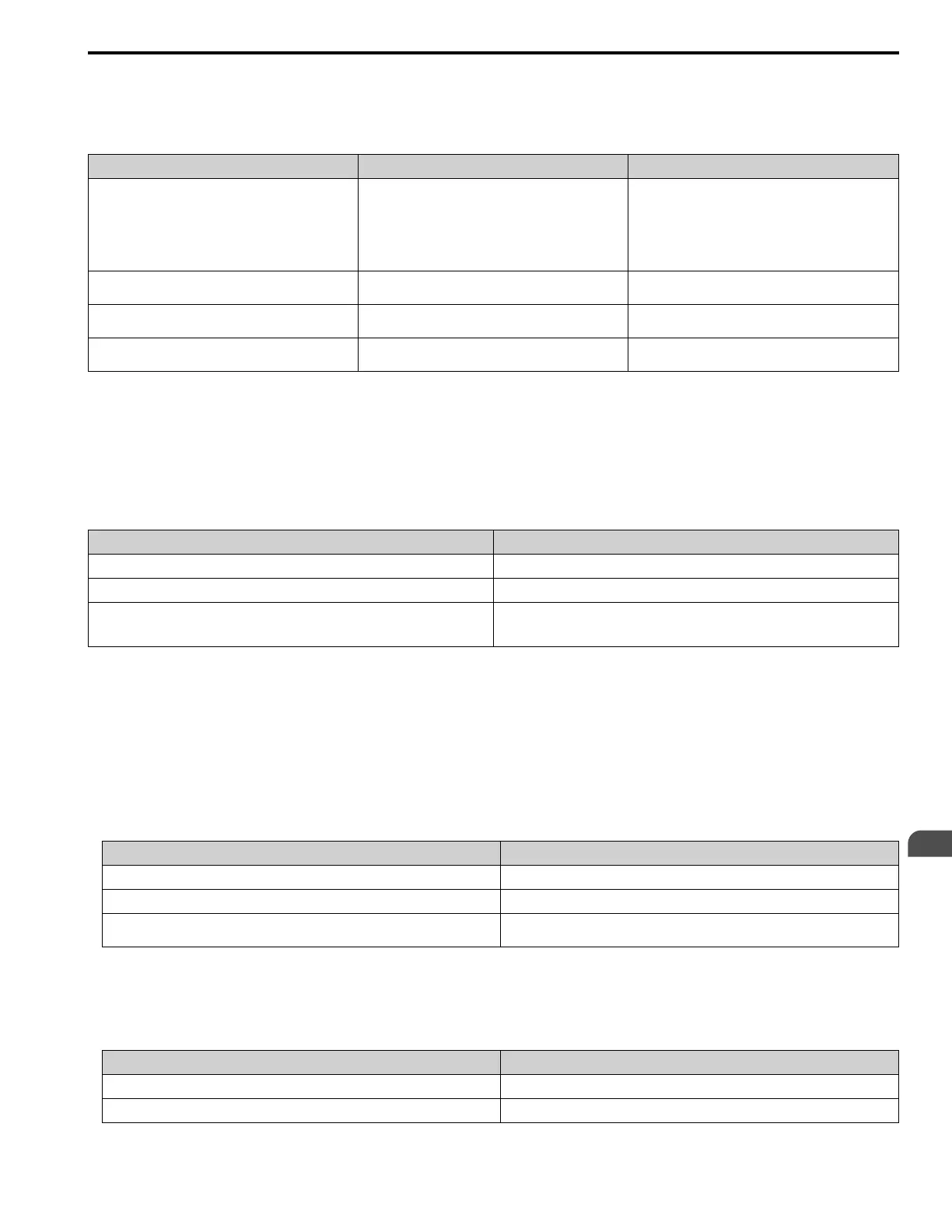

■ PID Control Applications

Table 5.22 shows applications for PID control.

Table 5.22 PID Control Applications

Application Control Content Sensors Used

Speed Control • The drive uses a feedback signal for the machine speed,

and adjusts that speed to align with the target value.

• The drive uses speed data from other machinery as the

target value to do synchronous control. The drive then

adds that target value to the feedback from the machine

it is operating to align its speed with the other

machinery.

Tacho generator

Pressure control The drive uses feedback from the actual pressure to hold

constant pressure.

Pressure sensor

Flow control The drive uses feedback from the actual flow to hold

constant flow.

Flow rate sensor

Temperature control The drive uses feedback from the actual temperature to

control a fan and hold constant temperature.

Thermocoupler, thermistor

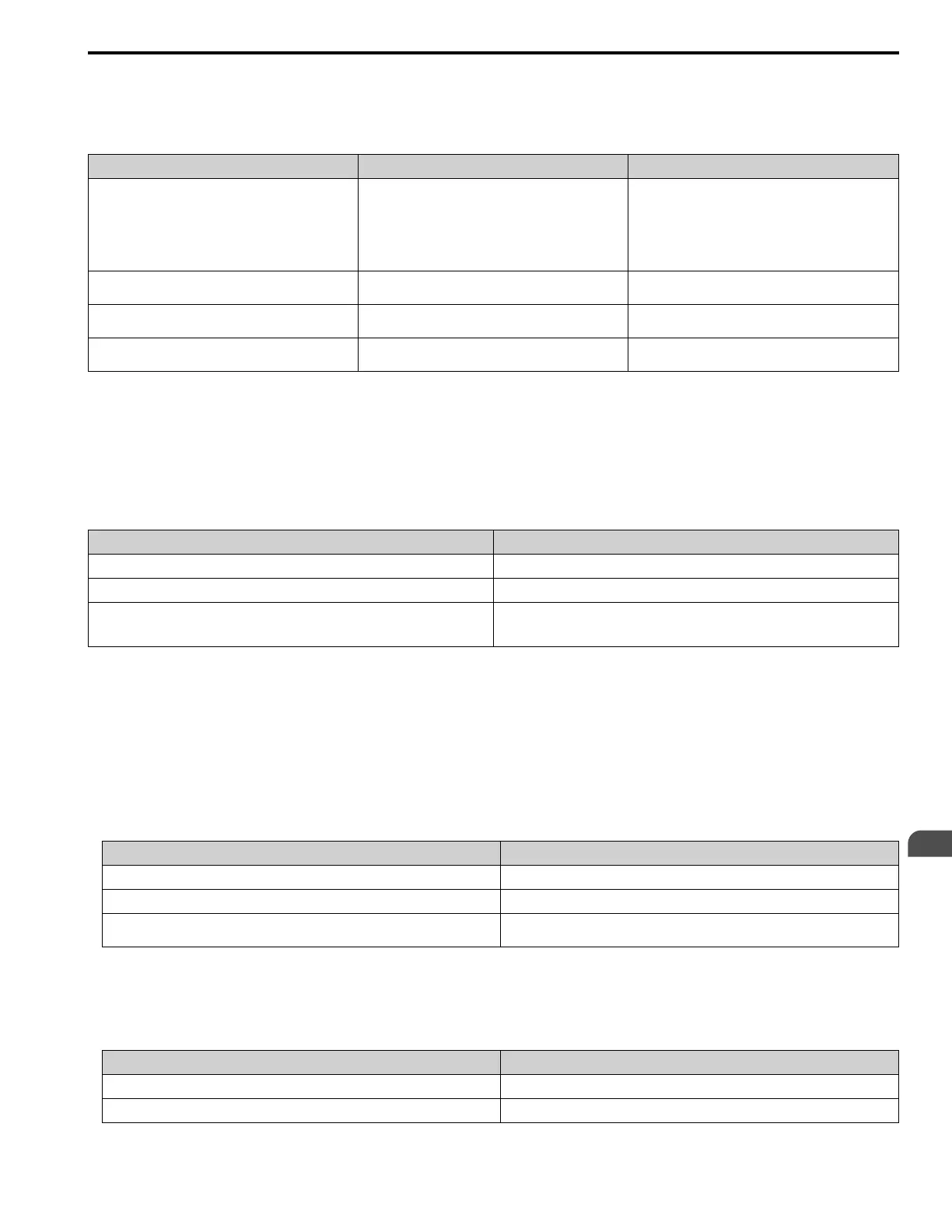

■ Input Methods for the PID Setpoint

Use b5-01 [PID Mode Setting] to select how the PID setpoint is input to the drive.

When b5-01 = 1 [Standard], the frequency reference set in b1-01 [Frequency Reference Selection 1] will be the PID

setpoint, or the one of the values shown in Table 5.23 will be the PID setpoint.

When b5-01 = 3 [Fref + PID Trim], one of the inputs in Table 5.23 will be the PID setpoint.

Table 5.23 Input Methods for the PID Setpoint

Input Methods for the PID Setpoint Setting Value

MFAI terminal A1 Set H3-02 = C [Terminal A1 Function Selection = PID Setpoint].

MFAI terminal A2 Set H3-10 [Terminal A2 Function Selection] = C.

MEMOBUS/Modbus register 0006H Sets MEMOBUS/Modbus register 000FH (Control Selection Setting) bit 1 to 1 (PID

setpoint input). Enters the PID setpoint to MEMOBUS/Modbus register 0006H (PID

setpoint, 0.01% units, signed).

Note:

If you set two inputs for the PID setpoint, it will trigger operation error oPE07 [Analog Input Selection Error].

■ Entering the PID Feedback Value

You can use two methods to input the PID feedback value to the drive. One method uses a single feedback signal for

usual PID control. The other method uses two signals. The difference between those signals sets the deviation.

• Use One Feedback Signal

Use Table 5.24 to select how the feedback signal is input to the drive for PID control.

Table 5.24 PID Feedback Input Method

PID Feedback Input Method Setting Value

MFAI terminal A1 Set H3-02 = B [PID Feedback].

MFAI terminal A2 Set H3-10 = B.

MEMOBUS/Modbus register 15FFH Enters the PID setpoint to MEMOBUS/Modbus register 15FFH (PID setpoint, 0.01%

units, signed).

• Use Two Feedback Signals and Calculate the Deviation from the Difference Between Those Signals

Use Table 5.25 to select how the second feedback value is input to the drive. The drive calculates the deviation of

the second feedback value. Set H3-02 or H3-10 = 16 [Terminal A1/A2 Function Selection = Differential PID

Feedback] to enable the second feedback signal used to calculated the deviation.

Table 5.25 PID Differential Feedback Input Method

PID Differential Feedback Input Method Setting Value

MFAI terminal A1 Set H3-02 = 16.

MFAI terminal A2 Set H3-10 = 16.

Loading...

Loading...