< 6. Operation >

6-1

IM 12F5A1-01E

6. OPERATION

6.1 PreparationforOperation

6.1.1 InspectingPipingandCableInstallationCondition

ConrmthatthepipingandwiringtotheFC400Gfreeavailablechlorineanalyzerhavebeencorrectly

installed. For details of wiring, refer to Sec. 3.3.

6.1.2 FillingwithCeramicBeadsforElectrodePolishing

Surface contamination of the indicator electrode results in measured value error. To avoid

contamination-caused error, the electrode surface is continuously polished by ceramic beads during

FC400G operation.

Ceramicbeadsarenotlledintothebeadscaseatfactoryshipment.Thus,pourtheceramicbeads

providedintheaccessoryboxintothebeadscaseasfollowsbeforestartingtheFC400G.

The combined chlorine insensitive version uses glass beads.

Beforeoperation,ceramicbeadsarelledintothebeadscaseofthedetector.

[Howtolltheceramicbeads]

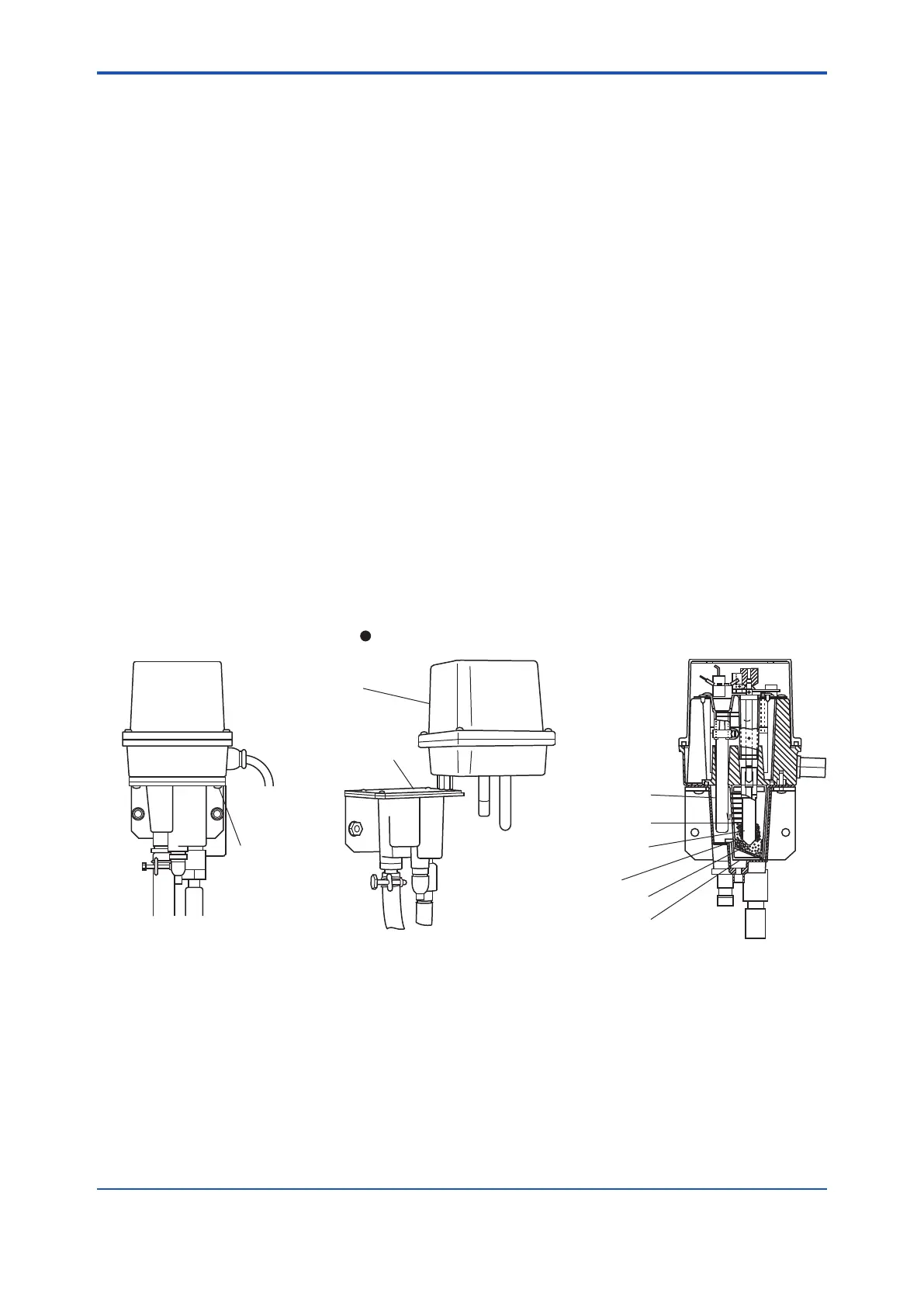

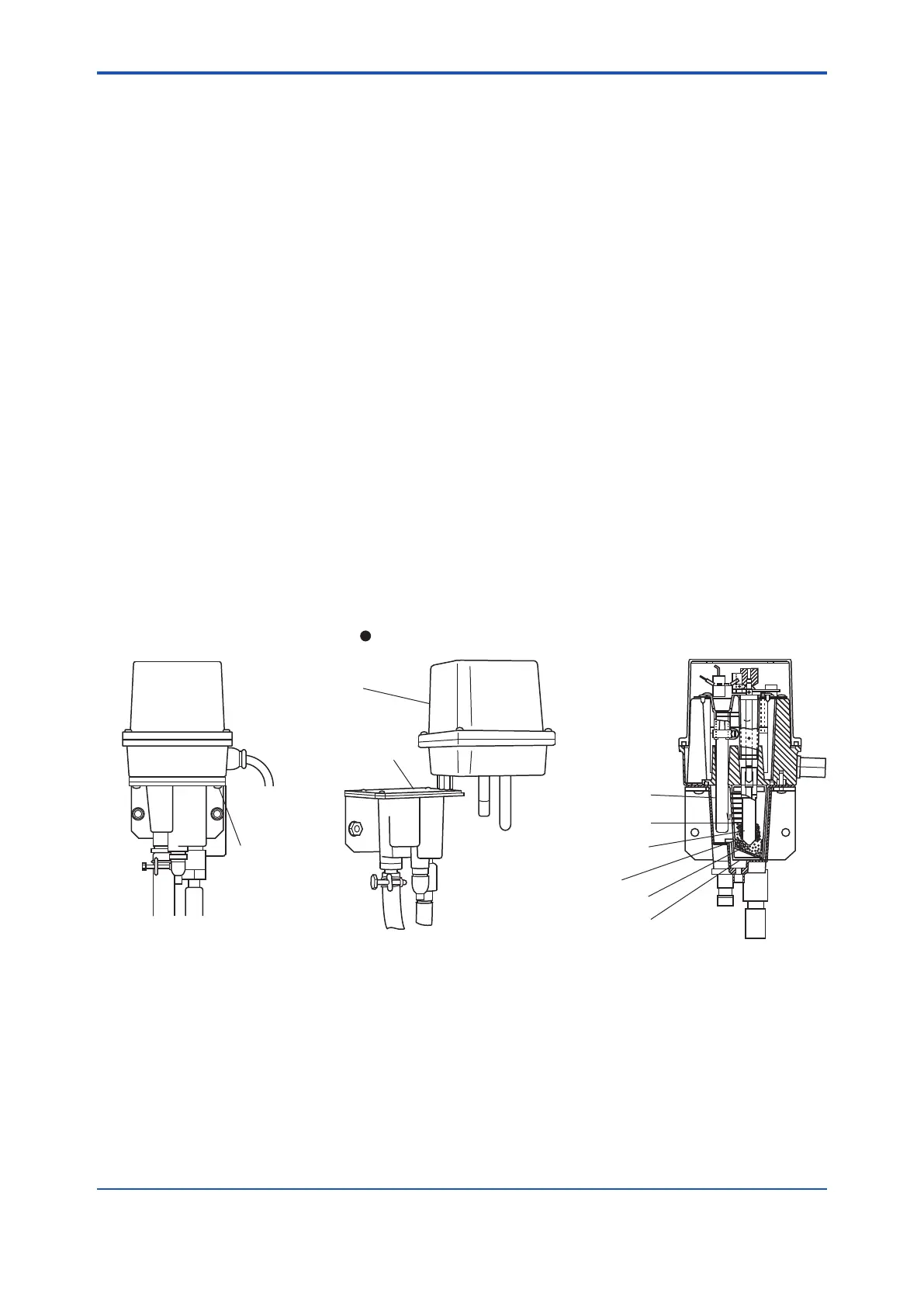

Unscrewtwoxingscrewsatthebottomoftheelectrodemechanismblock(seeFigure6.3)toremove

the measuring tank.

Theceramicbeadsarenormallylleduptothebottommostnotchofthebeadscasewhenthe

indicator electrode is inserted.

F6.1e.ai

Electrode mechanism

block

Measuring tank

Fixing screws

( 2 pcs )

In maintenance position

Counter electrode

(reference electrode)

Indicator electrode

(rotating electrode)

Beads case

Ceramic beads

Beads case cover

The bottommost notch

of the beads case

Figure6.1 MeasuringTankPartsandBeadsCase

Loading...

Loading...