< 9. Troubleshooting >

9-4

IM 12F5A1-01E

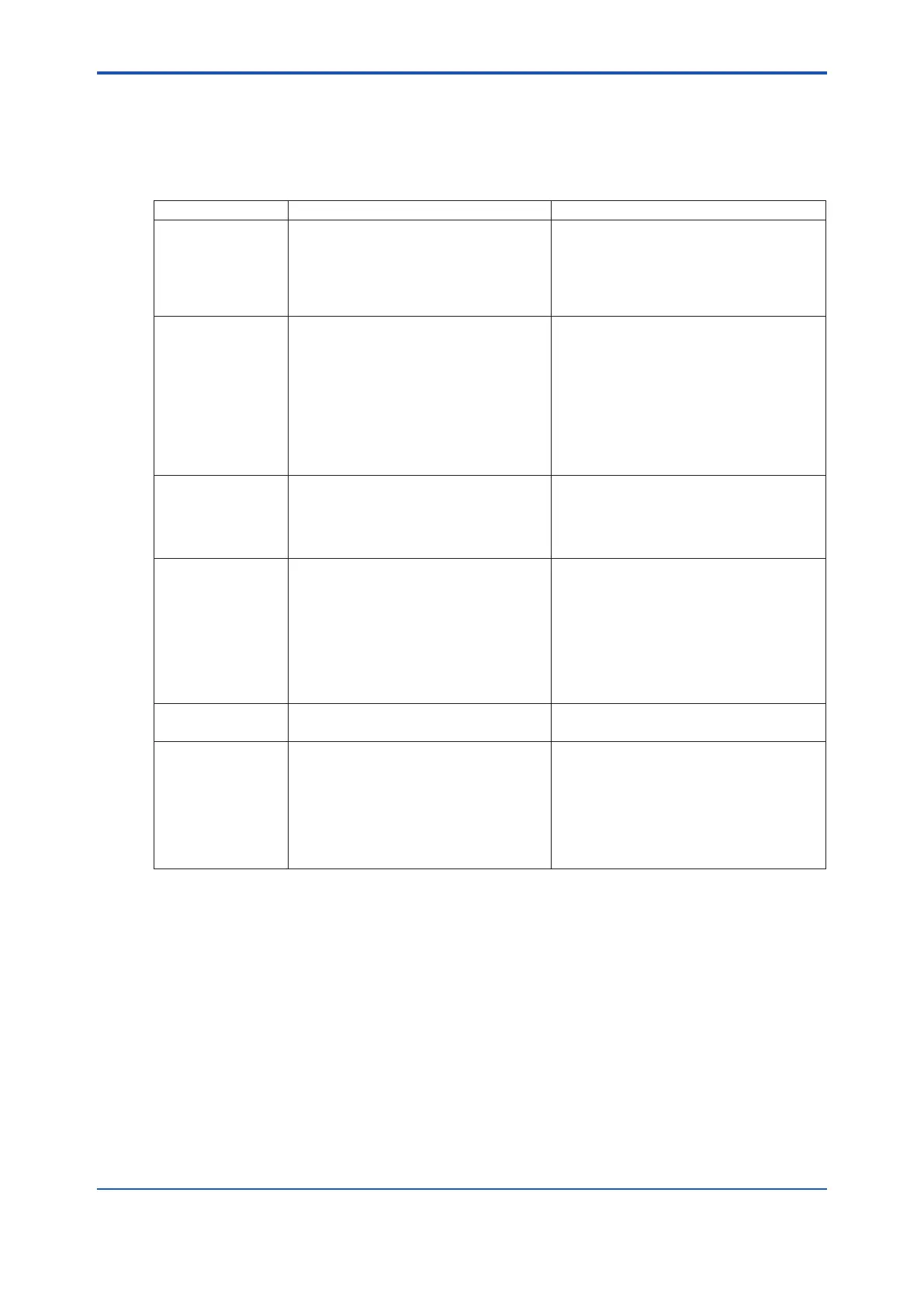

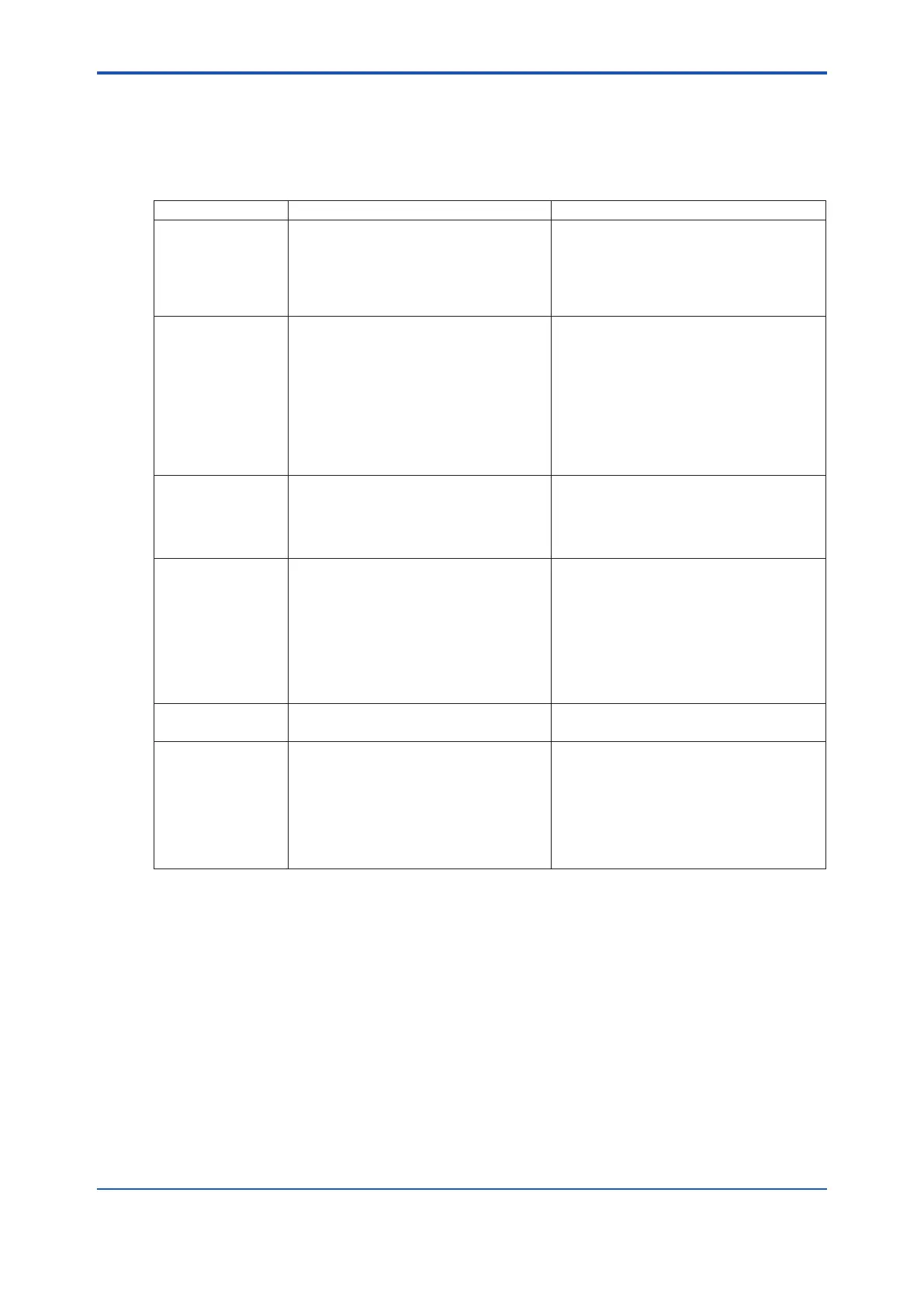

9.2 FortheCaseWhereNoErrorIndicationAppears

Therearecaseswherenormalmeasurementisprevented,suchasinuctuatingsetvalueeven

though no error is detected. Table 9.2 shows such abnormalities, possible causes, and remedies.

Table9.2 Abnormalities,TheirPossibleCauses,andRemedies

Abnormalities PossibleCauses Remedies

Measured value is

abnormal.

1. Indicator electrode has stopped.

a. Electrode drive belt does not turn.

b. Cell motor does not run.

2. Indicator electrode has worn out.

3.Insucientcontinuityattheelectrode

mechanism block.

1. Take steps as follows :

a.Sucientlytightenthesetscrew.

b. Replace the motor with a new one.

2. Replace the electrode with a new one.

3. Replace the rotating contact (see Sec.

8.2.1).

Measurement error

is large.

1. Indicator electrode has been

contaminated.

2.Zeroand/orspanhasnotbeen

correctlyadjusted.

3. Auto zero calibration abnormal.

1. Polish the indicator electrode in

accordancewithSec.8.1.1also,clean

the ceramic beads in accordance

withSec.8.1.2(ifitisnotpossibleto

sucientlycleanthebeads,replace

them with new ones).

2. Conduct zero and / or span calibration.

3a.Replaceactivatedcharcoallter

3b. Piping related to auto zero calibration

is blocked

Measured value

uctuateslargely.

1. Indicator electrode does not rotate at

constant speed.

2.Insucientcontinuityattheelectrode

mechanism block

1. Check if the set screws have loosened.

Check if the belt, driven shaft assembly

is normal.

If not, replace them.

2. Replace the rotating contact.

Measured value

does not vary.

1. Measuring tank has no sample

water.

2. Electrode to electrode circuit is open.

3. No voltage is applied between the

indicator and counter electrodes.

1. Repair abnormality such as piping

disconnection or sample water feed

failure to normal condition

2. Repair open circuit. If open circuit

occurs in an electrode, replace such

electrode.

3. Check the converter.

Abnormal analog

output

1. Lead resistance is too large.

2. Output circuit abnormal.

1.Reducetheresistanceto550Ωorless.

2. Contact YOKOGAWA.

The reading

deviatessignicantly

in the positive

(or negative)

direction, or

overshoot occurs.

1. Span calibration has not been

performed correctly. Span calibration

was performed with electrode

sensitivity initialization set to ON (1)

inservicecode08("CHANG"Mode)

and using a calibration solution with

alargedierenceinconcentration

from the input concentration value.

1. Set electrode sensitivity initialization to

ON(1)inservicecode08("CHANG"

Mode) and perform calibration again.

(See item (f) in Sec. 5.4.2, Sec. 7.3)

Loading...

Loading...