< 6. Operation >

6-2

IM 12F5A1-01E

6.1.3 SupplyingSampleWater

Beforestartingtosupplywatertobemeasured,conrmthattheneedlevalvesintheFC400Gandthe

samplingsystemareclosed.Whenit’sdiculttoviewtheliquidsurfaceinthemeasuringtankfrom

outside,checkthetankwhenit’stimeforelectrodemaintenance(refertoFigure6.3).

(1) When there is no Sampling System

ThesamplesupplypressuretotheFC400Gshouldbe1to150kPa,andowshouldbe0.1to

2.5 l/min.

Next,slowlyopentheneedlevalveoftheFC400Gtoadjustthewaterow.

• Thewatershouldowcontinuouslyalongthewholelengthoftheelectrode,fromthetipto

whereitentersthewater(minimumow0.1l/min.)

• Liquidowshouldnotbesuchthatwatersplashesonthebaseoftheelectrode(maximum

ow2.5l/min.)Checkthatthereisnoleakagefromthepipingorfromthebreatherholeofthe

tank.

(2) When the FC400G is used with ST401G Sampling System.

Thesamplesupplypressureshouldbe100to750kPa,andowshouldbe0.1to10l/min.Adjust

owusingneedlevalveasdescribedin(1)above.

(Note) Refer to the Instruction Manual IM12A0V2-E of the ST401G Sampling System.

6.1.4 PolishingtheIndicatorElectrode

The electrode surface of the indicator electrode must always be kept clean. Polish the electrode

surface as follows:

(1) Press the

MODE

key on the converter to enter the operation level and press the

YES

NO

key to select the <CELL> mode (cell motor ON / OFF). Press the

NO

key with respect to the

message “CELL ON” displayed to stop the rotation of the indicator electrode.

Whentheelectrodestopsrotating,theCELLlampextinguishes.

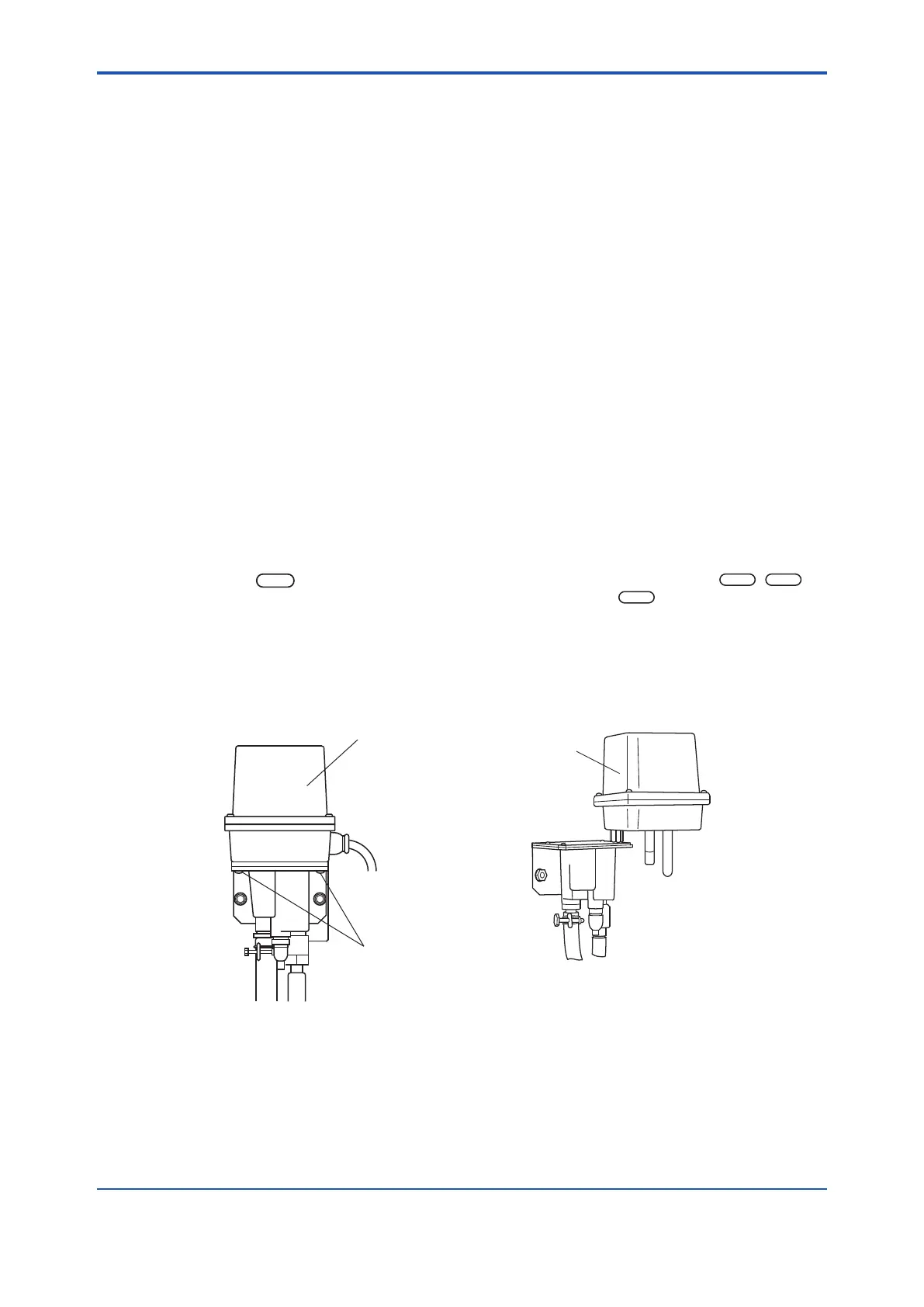

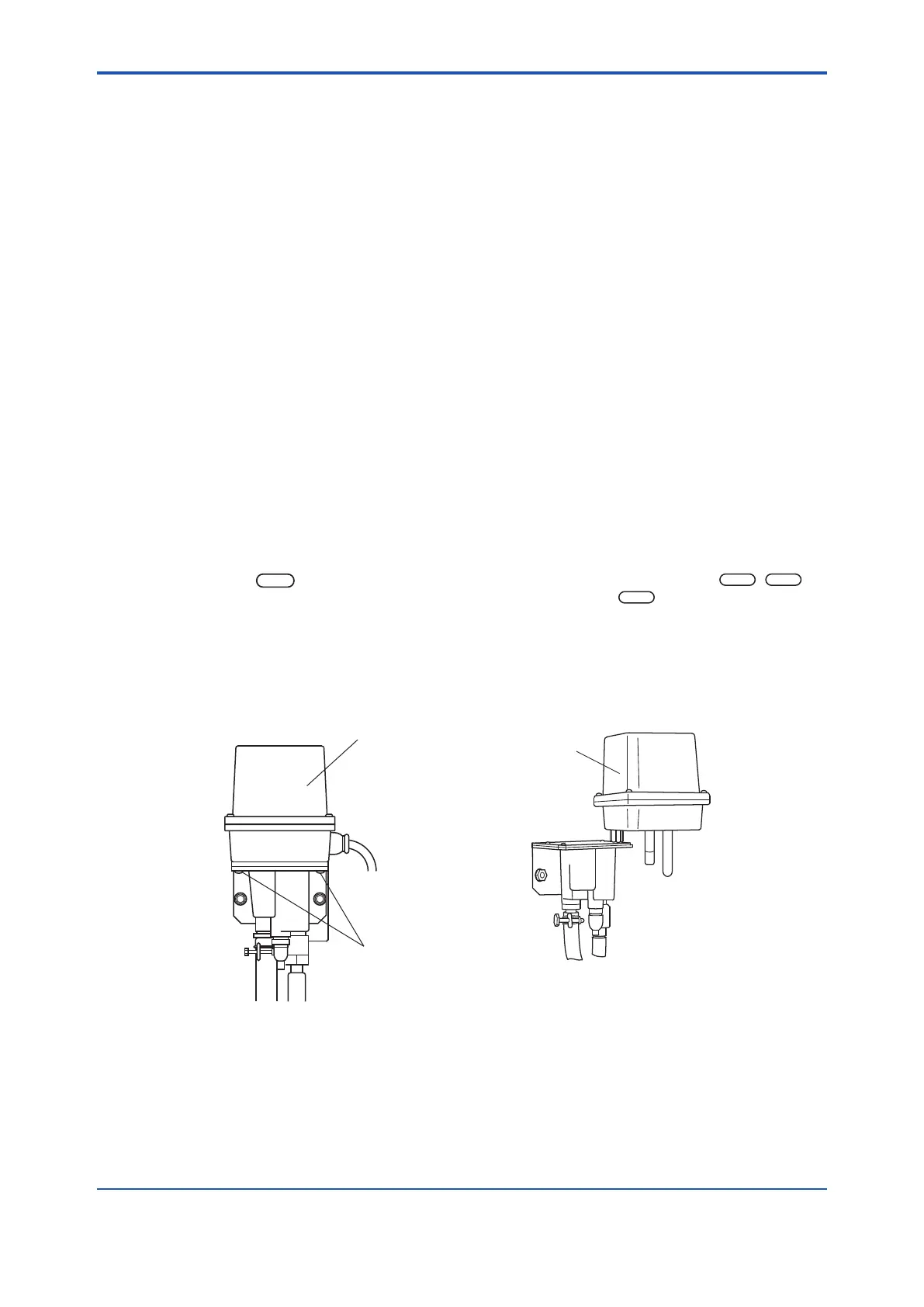

Remove the electrode mechanism block from the measuring tank and set up the block as shown

inFigure6.3.Theelectrodemechanismblockisxedtothemeasuringtankusingtwoscrewsat

the lower part of the mechanism block.

Fixing screws

(2 pcs)

Electrode

mechanism block

F6.3e.ai

Electrode mechanism

block cover

Figure6.2 ElectrodeMechanism Figure6.3 UnderMaintenance

BlockFixingScrews

Loading...

Loading...