< 8. Maintenance >

8-1

IM 12F5A1-01E

8. INSPECTIONANDMAINTENANCE

This chapter describes the inspection and maintenance required to maintain the FC400G

operation in good condition.

8.1 InspectionandMaintenanceItemsand

Implementation Cycle

The table below shows the principal inspection and maintenance items and recommended

maintenance intervals to maintain good operating condition.

Actual maintenance intervals must be determined in accordance with individual operating

conditions.

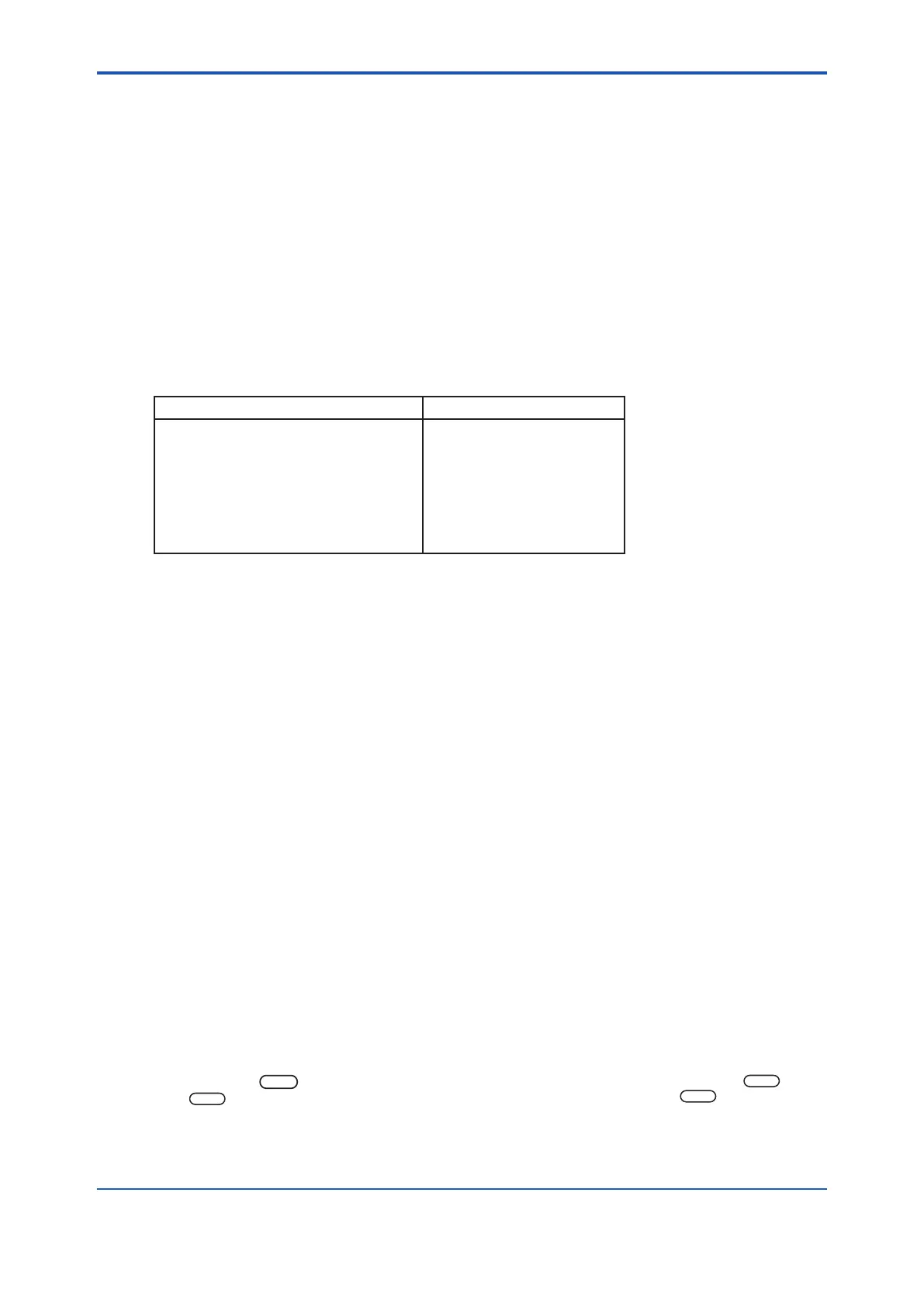

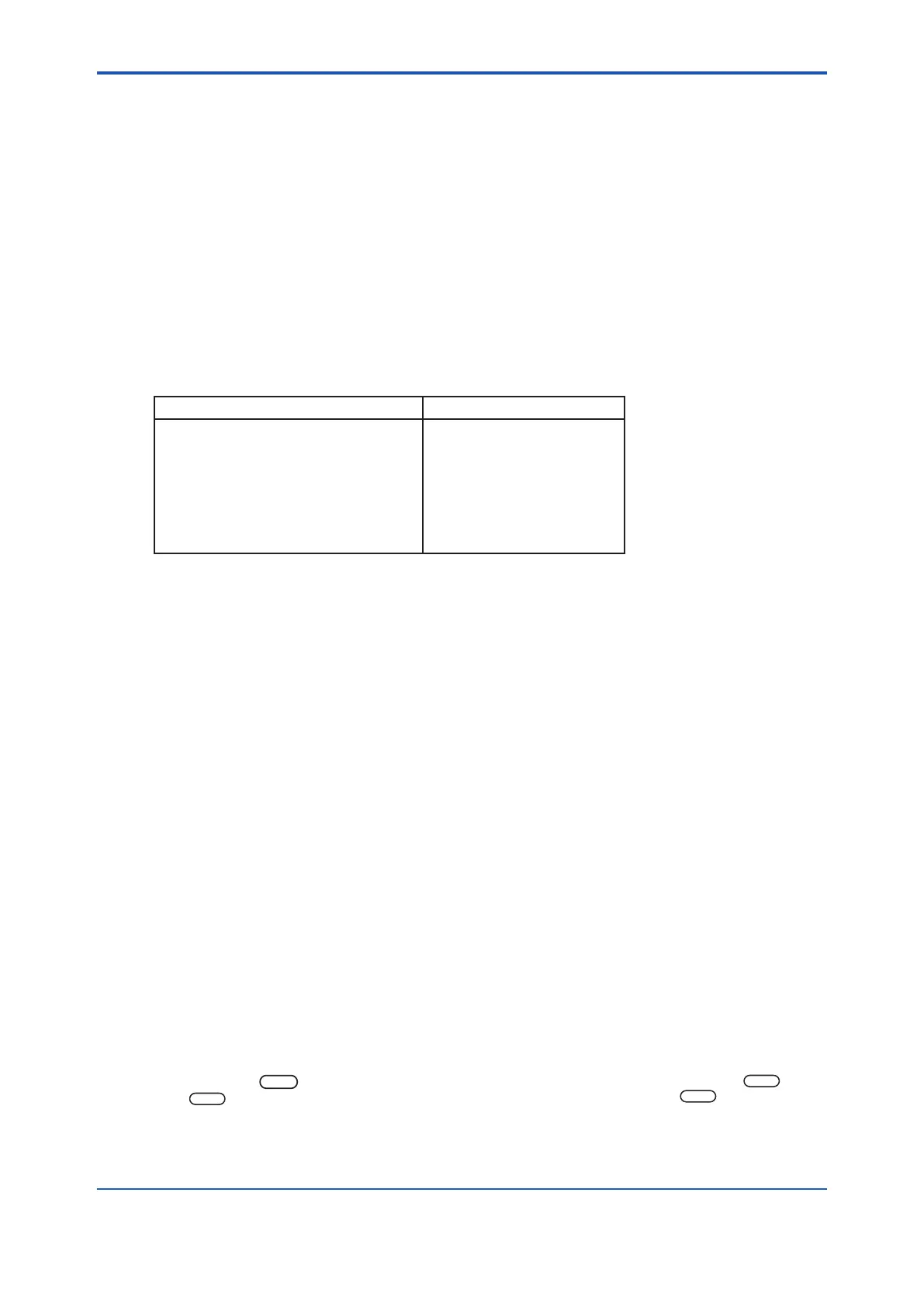

Table8.1 InspectionandMaintenanceItemsandImplementationCycle

Inspection and Maintenance Items Implementation Cycle

●Polishing of indicator electrode

●Replacementofindicatorelectrode

●Ceramicbeadscleaning

●Replacementofceramicbeads

●Measuringtankcleaning

●Calibration

●Replacementofactivatedcharcoallter

Monthly

Once a year

Every 3 months

Once a year

Every 3 months

Monthly

Once a year

Note: Appropriate maintenance intervals must be determined in accordance with the condition or contamination. Same applies (to

decreaseofinuenceof)combinedchlorineinsensitiveversionwithgoldalloyelectrodeandglassbeads.

8.1.1 PolishingtheIndicatorElectrode

Theindicatorelectrodeconstantlyrotatesat600rpm(at50Hz)andisautomaticallycontinuously

polishedwithceramicbeads.However,thisdoesnotcompletelypreventadhesionof

contamination; contamination gradually accumulates on the electrode surface over time.

A contaminated electrode surface is a cause of measurement error. The degree of this

measurement error increases depending on the amount of contamination. Therefore, the

electrode surface must be polished using abrasive (alumina) to remove such contamination

beforemeasurementerrorexceedstheallowance.

Polishingfrequencydierswiththequalityofthesamplewater.Polishingeveryafewmonths

maybesucientinsomecases.However,ingeneral,itisrecommendedthattheindicator

electrode be polished every month. For polishing procedure, follow

Sec.6.1.4, when the electrode

is polished, zero point and span must always be calibrated.

Whiletheindicatorelectroderotatesat600rpm(at50Hz),theelectrodeisautomaticallypolished

withceramicbeads.However,thisdoesnotcompletelypreventadhesionofcontamination;

contamination gradually accumulates on the electrode surface over time. Therefore, the

electrode surface must be polished manually with polishing powder (alumina) to remove

suchcontaminationbeforethemeasurementerrorexceedstheallowance.Forthepolishing

procedure,followSec.6.1.4.Inparticular,polishtheelectrodesurfaceasdescribedwhenithas

become corrugated or deformed from the original shape (circle with a diameter of about 3 mm).

Note: It is recommended to polish the indicator electrode every month. Every two or three months

maybesucientinsomecases;therequiredpolishingfrequencydierswiththequalityof

the sampling water. After polishing the electrode surface, conduct calibration with running-in

operation.

(1) Press the

MODE

key on the converter to enter the operation level and press the

YES

NO

key to select the <CELL> mode (cell motor ON / OFF). Press the

NO

key with

respect to the message “CELL ON” displayed to stop the rotation of the indicator electrode.

Whentheelectrodestopsrotating,theCELLlampextinguishes.

Remove the electrode mechanism block from the measuring tank and set up the block as

Loading...

Loading...