< 8. Maintenance >

8-4

IM 12F5A1-01E

8.1.4 ReplacementofActivatedCharcoalFilter

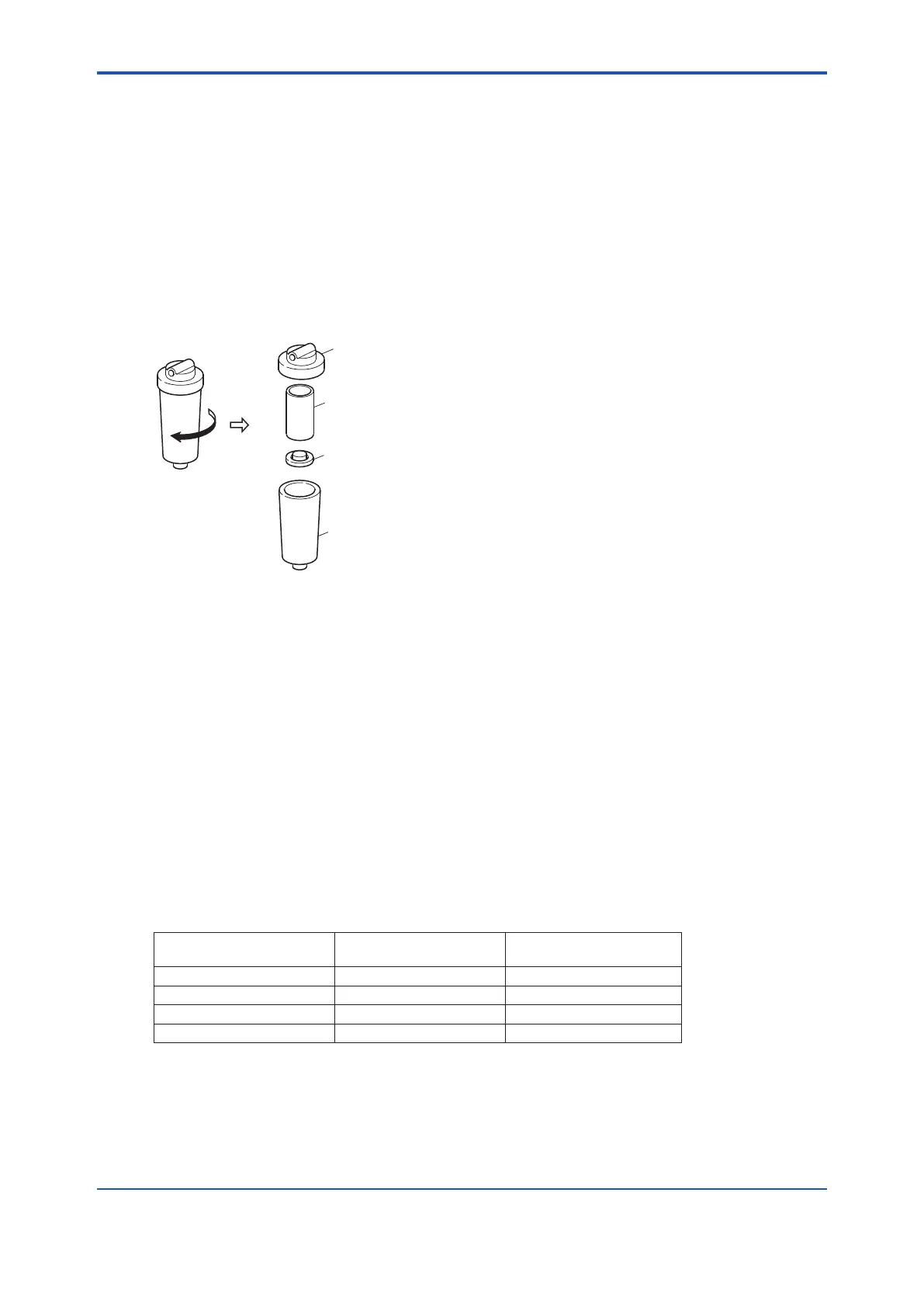

(1) CloseBV1andBV2,thenrotateltercasetoremove(seeFigure8.4).

(2) Clean inside of case with brush or the like.

(3) AsillustratedinFigure,replacelterwithnewone.

(4) Reassemble using the reverse procedure, then open BV3 and BV1 to pass water through

lter. Checkthattherearenowaterleaksfromlterandpiping,andno

bubbles in drain water.

(5) Operateforabout20min.thenconrmthatfreeavailablechlorineanalyzerreadingisnear

zero.

(6) CloseBV3andopenBV2ballvalve.

Lid

(held in place by piping)

Spacer

Filter (activated charcoal)

Filter case

Turn

Figure8.4 ReplacingActivatedCharcoalFilter

8.2 CheckingtheElectrodeMechanismBlock,

and Replacing Damaged Parts

Detectorelectrodepartssuchasthemotorassemblyanddrivenshaftassemblyhavenitelife.

Ifconditionsofuseorenvironmentareoutsideofspecications,theirlifemaybeshorterthan

wouldotherwisebeexpected.

Periodically check whether electrode mechanism block is operating normally. To check if

abnormal or not, refer to “Main Check List”; for a simple check whether calibration and the like is

abnormal,referto“AuxiliaryCheckList”.Alternatethesechecksforbestresults.

Whensuchpartsthataresubjecttoaginghavebeenoperatedfortheir“recommendedlifetime”,

it is recommended that you replace them even if you feel that there is still life left in them.

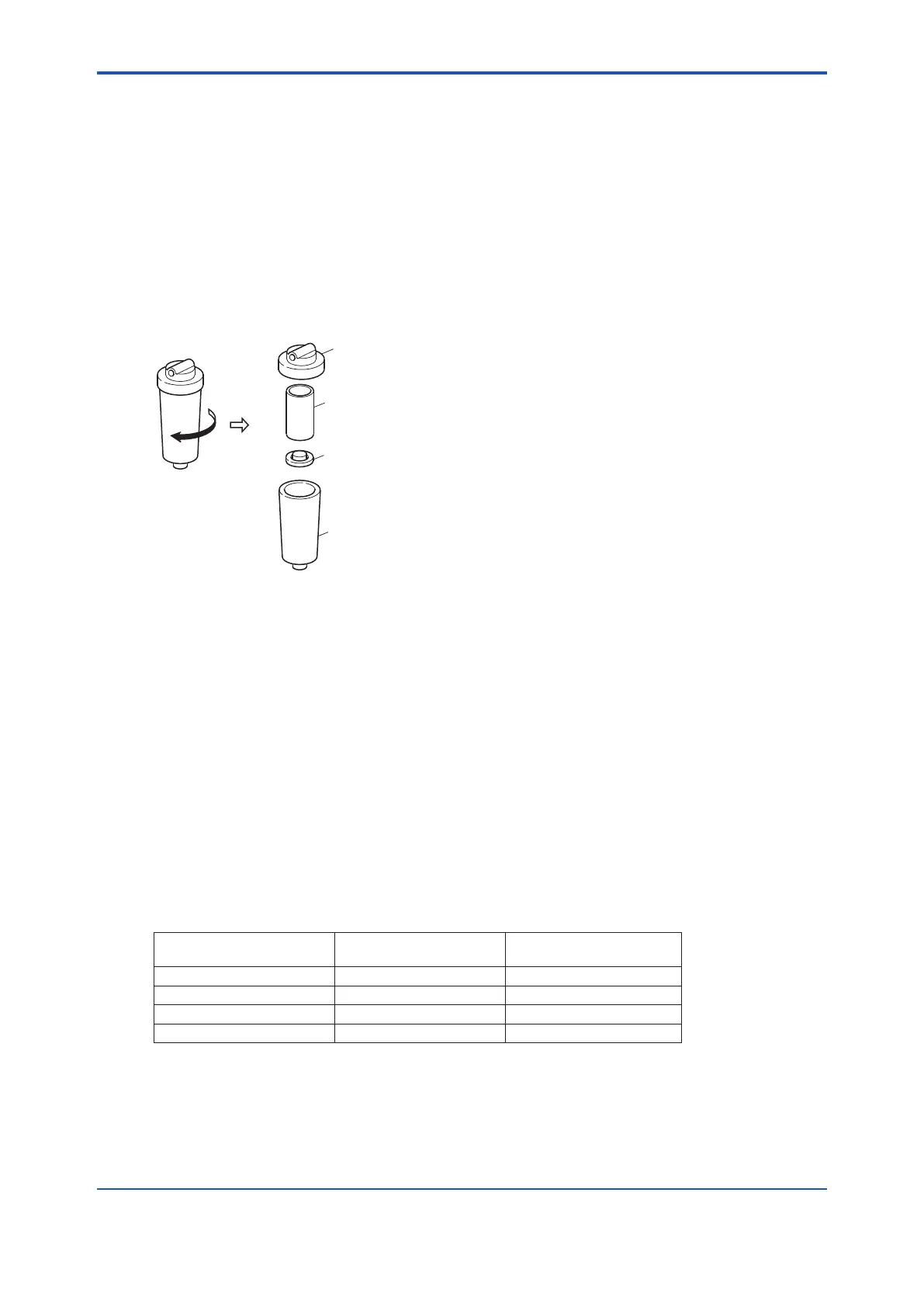

Table8.2showsalistofpartsthatwerecommendyoutoperiodicallycheckandreplace.

Table8.2 Partsrecommendedforperiodicchecksandreplacement

Part Recommended check

interval

Recommended

replacement interval

Rotating contact �* 1 year operation

Drive belt 6months(sub;3months.) 3 years operation

Driven shaft assembly 6months(sub;3months.) 3 years operation

Motor Assembly / gear head 6months(sub;3months.) 3 years operation

*: Rotating contact does not require inspection.

Loading...

Loading...