< 6. Operation >

6-3

IM 12F5A1-01E

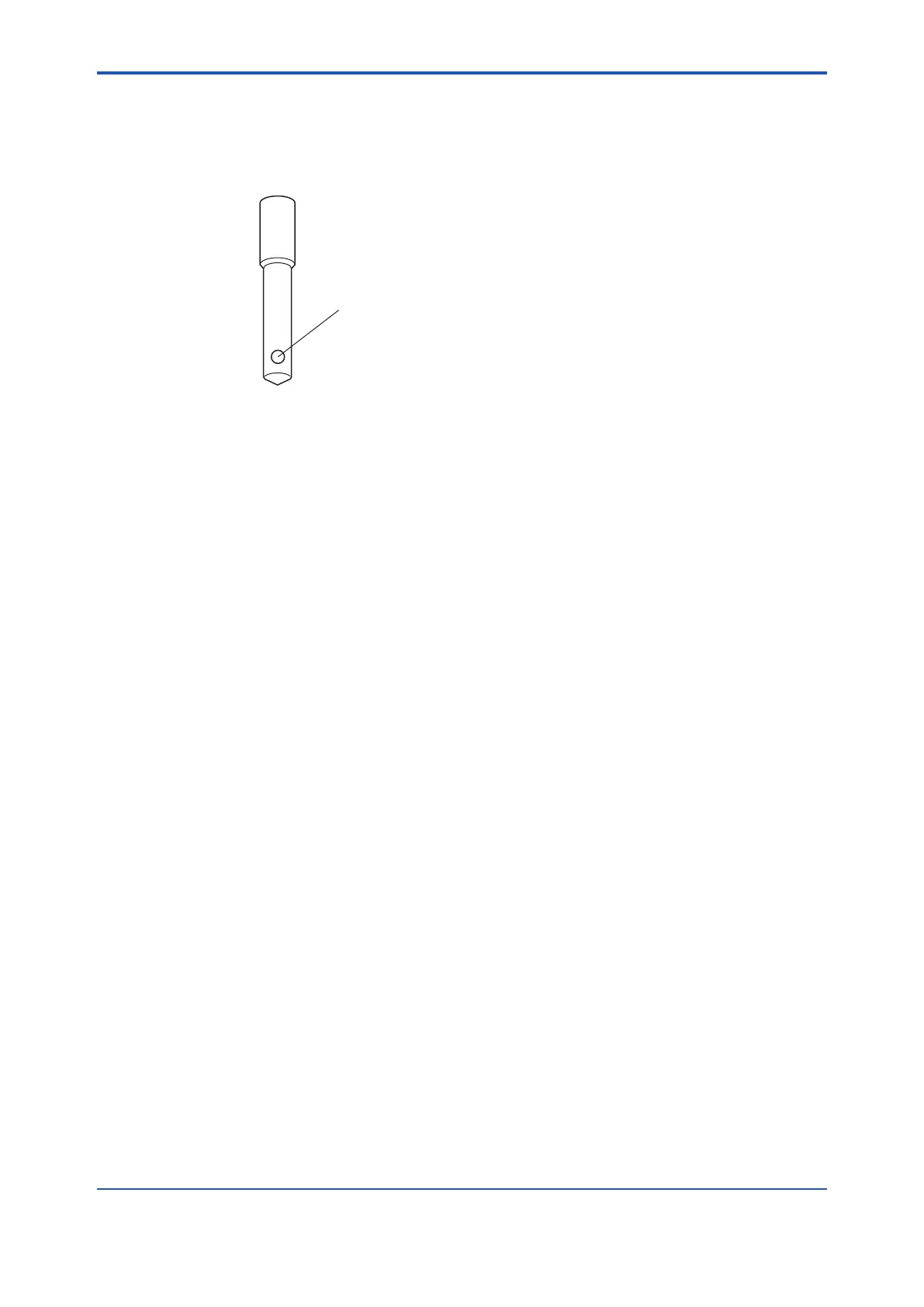

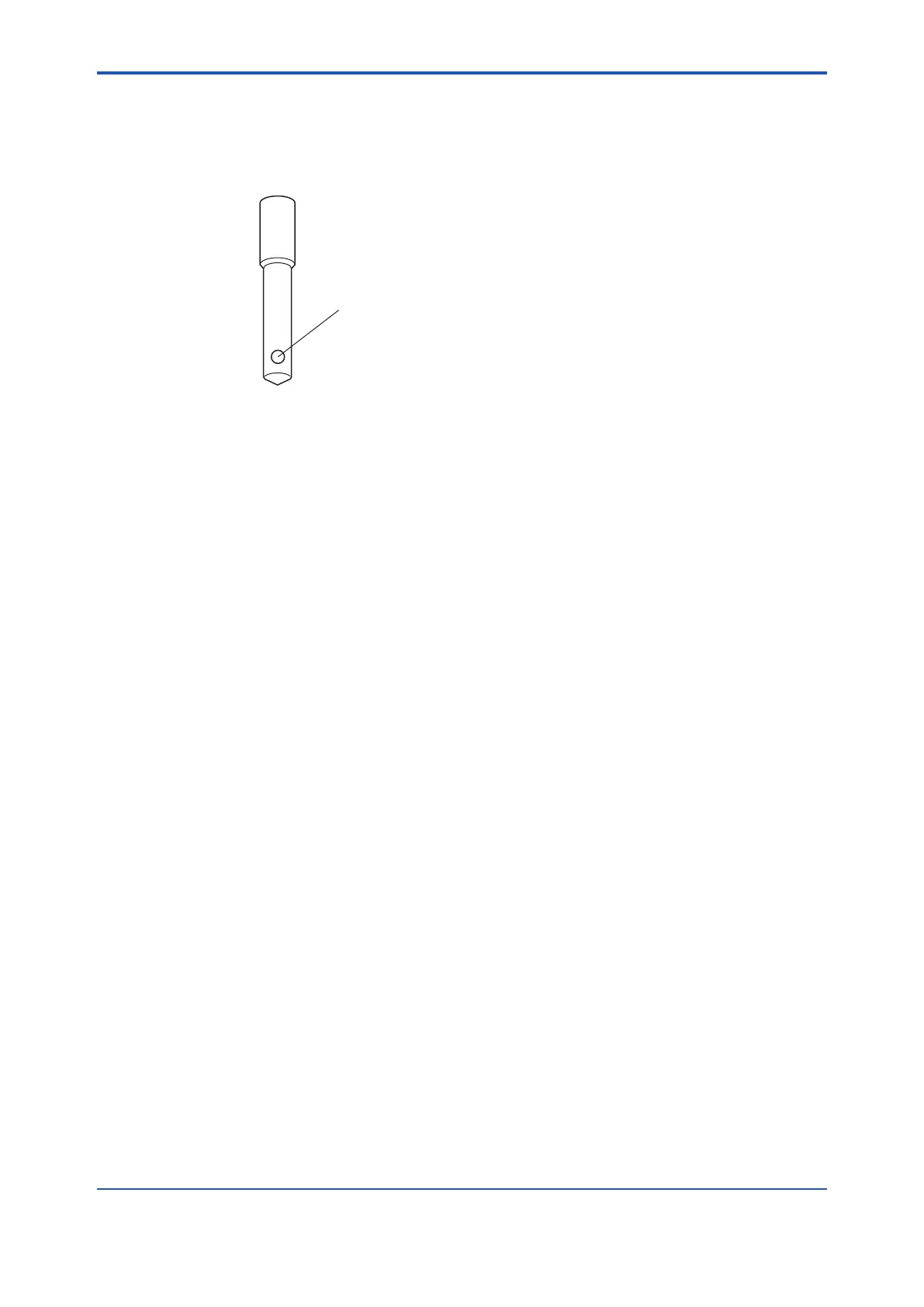

(2) Removing the Indicator Electrode

Removetheelectrodemechanismblockcoverfromthedetector.Holdthegearssothatthe

drive shaft does not turn and remove the indicator electrode. The electrode is screwed into the

drive shaft; turn the electrode counterclockwise. This time, do not touch the rotating contact. The

deformed rotating contact disables electrode function.

Figure6.4 AppearanceoftheIndicatorElectrode

(3) Polishing the Electrode Surface of the Indicator Electrode

Spread the provided abrasive (alumina) onto dampened gauze and thoroughly clean the

electrode surface using such gauze so that any contamination such as oil and grease is

completelyremoved.Thenwashoanyabrasivesadheringtotheelectrodeincleanrunning

water.

Afterpolishingandcleaning,conrmthatcontaminationhasbeencompletelyremoved.

The clean electrode surface must be uniformly wetted.

Note: Polish the electrode surface (gold electrode) by following the instructions below when it has

become corrugated or deformed from the original shape (about 3 mm in diameter).

Polishtheelectrodesurfacewithsandpaper(about#600)untilthesurfacebecomesnally

rounded. Then, polish it with sandpaper (about #2000), and lastly with polishing powder

(alumina). Make sure the electrode surface is clean and then install the indicator electrode.

Reduce the amount of ceramic beads if the electrode has deformed greatly. The ceramic

beadsshouldbelledupto5mmunderthebottommostnotchofthebeadscasewhenthe

indicator electrode is inserted.

(4) Installing the Indicator Electrode

Holdthegearssothatthedriveshaftdoesnotturn,andsucientlyscrewtheelectrodeintothe

shaft.Duringinstallation,exercisecarenottotouchtheelectrode surface.

Note: Polish the electrode surface again if you have touched it.

(5) Attach the electrode mechanism cover. Then, set the electrode mechanism block to the

measuringtankinplaceandfastenitusingthexingscrews.Finally,usethe<CELL>modein

the operation level to rotate the electrode.

6.1.5 SupplyingPower

Before supplying power, check that the fuse holder cap in the converter is not loose.

A power switch in the power line to the FC400G is used to turn power ON / OFF (the FC400G does

not have any internal power switch). Be careful not to turn on the power and cause an accident with

the indicator electrode or belt used to rotate it when the cover is removed or the electrodes are parked

inthemaintenancepositionshowninFigure6.3

(Note) When power is supplied, the instrument enters measurement mode.

Loading...

Loading...