<Toc> < 3. Operations >

3-3

IM 05D01C02-41E 3rd Edition: May 31, 2006-00

3.2 Setting Target Setpoint (SP)

The following operating procedure describes an example of setting 150.0 to a target

setpoint. In automatic operation, the controller starts control using set target setpoints.

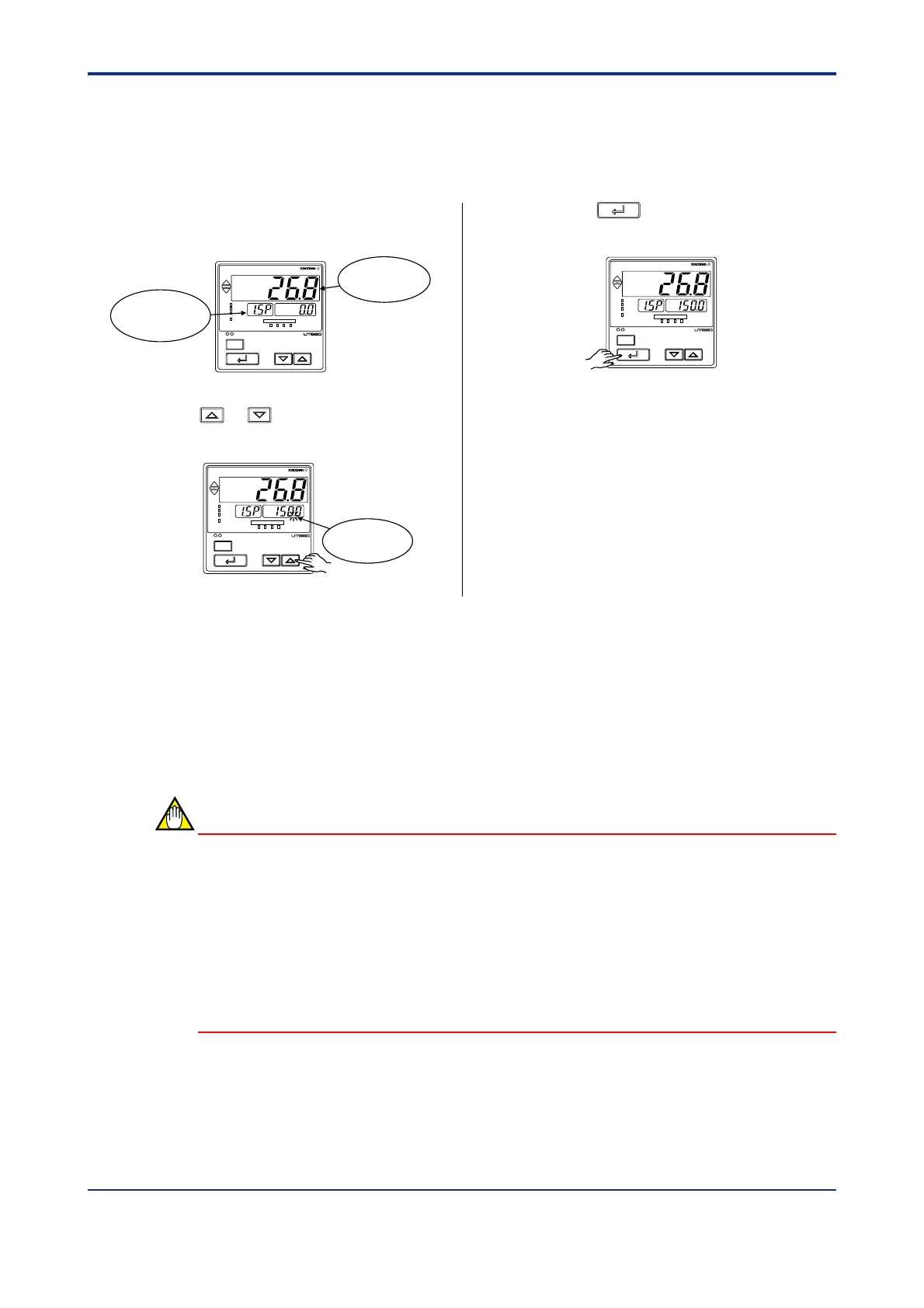

1. Bring the operating display into view

(display appears at power on).

SET/ENT

A/M

PV

AL1 2 3 4

REM

CAS

MAN

LP2

Displays PV.

Displays

target setpoint-1

“1.SP”.

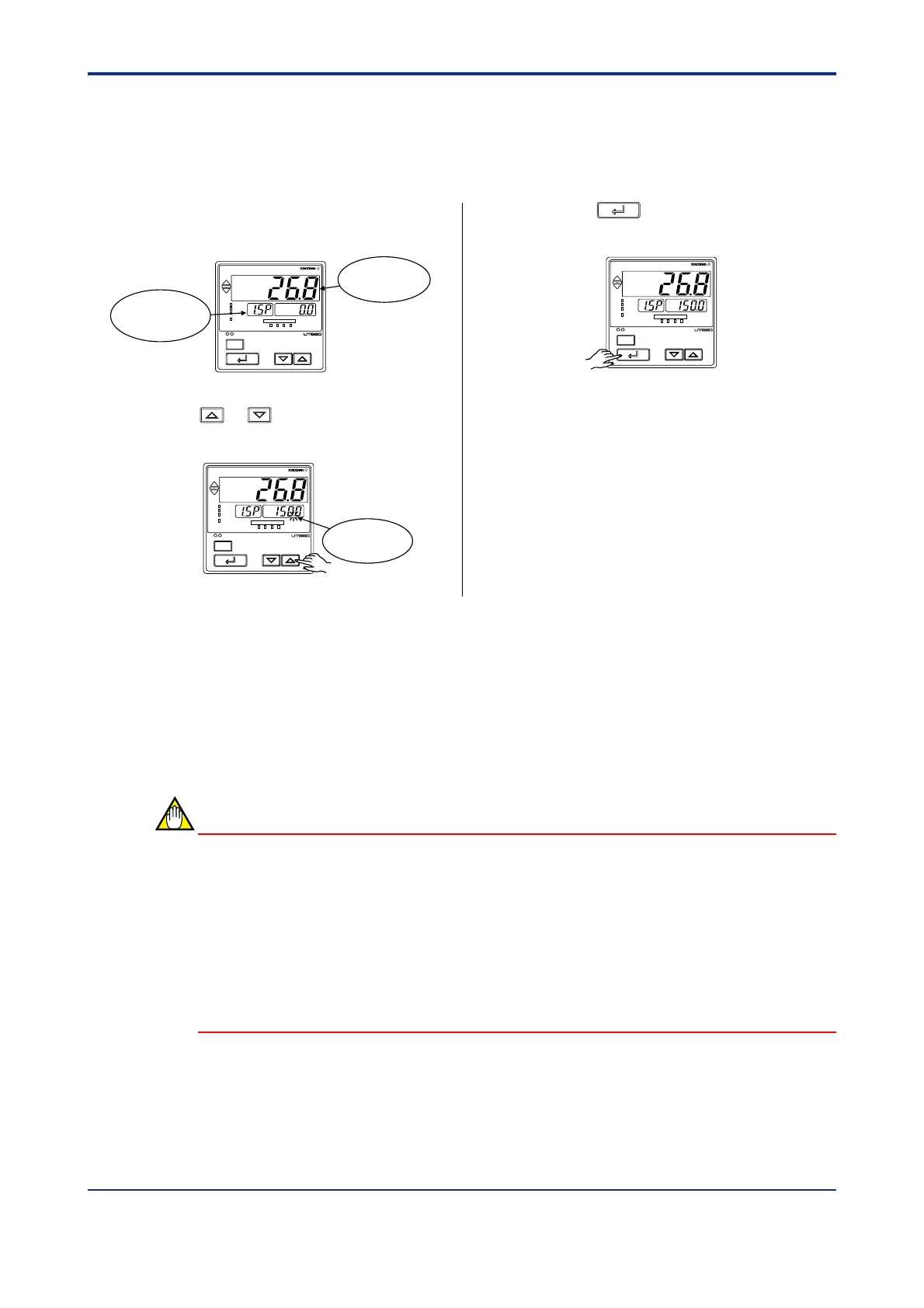

2. Press the or key to display the

required setpoint.

SET/ENT

A/M

PV

AL1 2 3 4

REM

CAS

MAN

LP2

Blinks during

change.

3. Press the

SET/ENT

key once to register the

setpoint.

SET/ENT

A/M

PV

AL1 2 3 4

REM

CAS

MAN

LP2

3.3 Performing/Canceling Auto-tuning

Auto-tuning should be carried out after setting a target setpoint (SP). Make sure the con-

troller is in automatic operation mode (AUTO) and in running state (RUN) before carrying

out auto-tuning. See “3.8 Switching between AUTO and MAN,” to change to AUTO and

“3.7 Switching between Run and Stop,” to change to Run.

NOTE

When on-off control is being used, auto-tuning cannot be carried out. Moreover, do not

perform auto-tuning when controlling any of the following processes.

• Control processes with quick response such as flow control or pressure control

• Processes where even temporary output on/off results in inconvenience

• Processes where a large output change at control element results in inconvenience

• Processes where variations in PV may exceed an allowable range, adversely affect-

ing product quality

Loading...

Loading...