2 3

1

1

HEALTH AND SAFETYINFORMATION

Device SafetyCompliance

The 3M™Attest™ Auto-reader390G complies with the following standards as

demonstrated by the CB Scheme Certificate and test report issued by Underwriters

Laboratories(UL):

•

IEC 61010-1(2001) Second Edition. Safety requirements for electrical equipment for

measurement, control, and laboratory use - Part 1: Generalrequirements

•

IEC 61010-2-010(2003) Second Edition. Safety requirements for electrical equipment

for measurement, control, and laboratory use - Part 2-010: Particular requirements for

laboratory equipment for the heating ofmaterials

The 3M™Attest™ Auto-reader390G is listed as Laboratory equipment and carries the

UL mark with adjacent indicators “C” and “US” based on compliance to the standards UL

61010-1and CAN/CSA 22.2No.61010-1.

The 3M™Attest™ Auto-reader390G complies with the CE mark related to the Low

Voltage Directive (LVD) 2006/95/EC as confirmed in the Declaration ofConformity.

The 3M™Attest™ Auto-reader390G complies with the RoHS Directive, Directive

2011/65/EU of the European Parliament and of the Council of 8June 2011on

the restriction of the use of certain hazardous substances in electrical and

electronicequipment.

The 3M™Attest™ Auto-reader390G complies with the WEEE Directive, Directive

2012/19/EU of the European Parliament and of the Council of 04July 2012on waste

electrical and electronic equipment(WEEE).

EMCCompliance

The 3M™Attest™ Auto-reader390G complies with the following EMC standards as

confirmed in the Certificate of Compliance generated by3M:

IEC 61326-1Electrical equipment for measurement, control and laboratory use - EMC

requirements - Part 1: Generalrequirements

The 3M™Attest™ Auto-reader390G complies with the EMC requirements of the CE

mark EMC Directive2004/108/EC.

The 3M™Attest™ Auto-reader390G complies with the Australian and New Zealand

electrical safety and electromagnetic compatibility requirements as confirmed in the

Supplier’s Declaration of Conformity that is linked to the Australian/New Zealand RCM

(Regulatory ComplianceMark).

Note: This equipment has been tested and found to comply with the limits for a Class A

digital device pursuant to Part 15, Subpart B, of the FCC Rules. These limits are designed

to provide a reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at their ownexpense.

This Class A digital device meets all requirements of the Canadian Interference-Causing

EquipmentRegulations.

Class 1LEDProduct

An investigation was conducted on the 3M™Attest™ Auto-reader390G per the

requirements of IEC 60825-1Ed. 1.2(A2:2001). The 3M™Attest™ Auto-reader390G is a

Class 1LED product with Class 1InternalRadiation.

The LED apertures are located at the bottom of each Incubator/Reader well perpendicular

to the opening of eachwell.

NOTE: Class 1products are safe for unprotected exposure of theeyes.

Caution - Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiationexposure.

Note: The use of the term “controls” in the above caution statement as required by

IEC 60825-1Ed. 1.2(A2:2001) refers to mechanisms by which the 3M™Attest™

Auto-reader390G may be controlled and not to the use of biological indicatorcontrols.

EXPLANATION OF PRODUCT AND PACKAGING

LABELSYMBOLS

Attention - Refer to the instructions foruse

Waste Electrical and Electronic Equipment (WEEE) and EU Battery Directive.

This symbol indicates that both the device and the lithium ion battery

contained therein need to be disposed of properly.

UL Listed to US and Canadian SafetyStandards

Mark of Conformity to EuropeanDirectives

Directcurrent

Compliant to all applicable ACMA regulatory arrangements(RCM)

Manufacturer

Catalognumber

Authorized representative for the EuropeanCommunity

Serialnumber

The 3M™Attest™ Auto-reader390G is not designed to incubate

3M™Attest™ 1264EO Biological Indicators, which have a sterilant

entry port in the center of the top of the cap. The 3M™Attest™

Auto-reader390G is designed to incubate and read only 3M™Attest™

Rapid Readout Biological Indicators for EO, catalog number 1294. Other

biological indicators (BIs) are not compatible with this device and cannot

beused.

Li

REF

1294

PREFACE

Manual RevisionHistory

Date Revision Reason For Revision

November 2012 A Initial Issue

February 2013 B

To clarify, in the Indications for Use section, that

Attest™1294Biological Indicators are used to

monitor the ethylene oxide sterilization process.

July 2013 C

To revise: the Warranty statement; and the WEEE

symbol and associated explanatory text.

ContentDisclaimers

PictorialDisclaimer

Sample printouts, graphics, displays and screens are for information and illustration

purposes only, and shall not be used for clinical or maintenance evaluations. Data shown

in sample printouts and screens do not reflect actual patient names or testresults.

HardwareDisclaimer

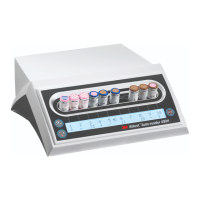

The 3M™Attest™ Auto-reader390G hardware specifications are subject to change.

The system images, hardware components and hardware specifications included in

the manual may not match the system installed. Any changes or modifications to the

authorized system installation have been verified as compatible with the functionality

outlined in thisdocument.

INDICATIONS FORUSE

The 3M™Attest™ Auto-reader390G is designed to incubate and automatically read the

3M™Attest™ Rapid Readout Biological Indicator for Ethylene Oxide, 1294, at 37°C for a

final fluorescent result at 4hours.

WARRANTY

The 3M™ Attest™ Auto-reader 390G has a one year limited product warranty. The US

warranty, remedy and limitations are described in the Price Quote form and in the Direct

Price Pages. For countries outside of the US, any warranty is established by the subsidiary

with responsibility for service of the 3M™ Attest™ Auto-reader 390G.

SerialNumber

For easy identification, each 3M™Attest™ Auto-reader390G has a unique serial number

printed on a label found on the back of the unit and displayed on the left side of the upper

row of text on the LCD Display when the user depresses the button. Please record

your serial number in this manual for future reference:___________________.

SAFETY ANDPRECAUTIONS

The 3M™Attest™ Auto-reader390G and its related devices and accessories are

designed to provide safe and reliable service when used according to the instructions

provided. Please read, understand, and follow all safety information contained in the

instructions for use included with the 3M™Attest™ Auto-reader390G and 1294Rapid

Readout Biological Indicator devices prior to use. Use this equipment only for the purpose

described in this Operator’s Manual. Retain these instructions for futurereference.

The unit is designed to be used only with the Power Supply module and Ethernet cable

supplied by 3M. If this product is used in a manner not specified, the protection provided

by the product may beimpaired.

Explanation of Single WordConsequences

Warning: Indicates a hazardous situation, which, if not avoided, could result in

death or seriousinjury.

Caution: Indicates a hazardous situation, which, if not avoided, could result in

minor or moderateinjury.

Warnings and SafetyPrecautions

The following warnings and precautions should be followed to avoid unsafe actions that

could result in personal injury or damage to theinstrument.

WARNING: To reduce the risk associated with hazardous voltage

Use indoors only.

Do not use the equipment if it is not working properly or if it has suffered any damage.

Use only the power supply specified for this product and certified for the country

ofuse.

CAUTION: To reduce the risk of injury or instrument damage

Do not spill liquid onto or into the instrument. Do not immerse the unit in liquid.

Always unplug the 3M™Attest™ Auto-reader390G and allow to cool before cleaning.

Clean external surfaces using only the instructions provided by the manufacturer.

Do not open the instrument housing – there are no user serviceable parts.

The instrument must be returned to the manufacturer for repair.

Allow the 3M™Attest™ Rapid Readout Biological Indicator to cool for the

recommended time period before activating. Activating or excessive handling of the

biological indicator before cooling may cause the glass ampoule to burst.

Wear safety glasses when activating the 3M™Attest™ Rapid Readout Biological

Indicator.

WARNING: To reduce the risk associated with incorrect results

Instrument is to be used by operators familiar with the device, device functionality, and

Operator’s Manual.

Do not place the instrument in environment exposed to sunlight or strong

incandescentlight.

Do not place instrument close to any device that emits a strong electro-magnetic field.

Do not use on a vibrating surface.

Match the cap color of the 3M™Attest™ Rapid Readout Biological Indicator with the

color-coded configuration sticker surrounding the 3M™Attest™ Auto-reader390G

incubation wells.

Do not remove or change placement of 3M™Attest™ Rapid Readout Biological

Indicator once it is placed into a well.

Do not remove the 3M™Attest™ Rapid Readout Biological Indicator from the

incubation well until the (+) or (-) symbol on the LCD panel indicates the test

iscomplete.

Caution: To reduce the risk associated with incorrect results

To avoid the possibility of the 3M™Attest™ Rapid Readout Biological Indicator

vial absorbing fluorescent residue from a chemical indicator or tape, place the

3M™Attest™ Rapid Readout Biological Indicator vial so it does not come in direct

contact with chemical indicators or tape.

Rendered on 9/12/2013 10:34:26 AM

Loading...

Loading...