110 ACS550 User’s Manual

Parameters

5 = DI3U,4D(R) – Defines digital inputs as the speed reference source (motor potentiometer control).

• Digital input

DI3 increases the speed (the U stands for “up”).

• Digital input

DI4 decreases the speed (the D stands for “down”).

• A Stop command resets the reference to zero (the

R stands for “reset”).

• Parameter 2205

ACCELER TIME 2 controls the reference signal’s rate of change.

6 =

DI3U,4D – Same as above (DI3U,4D(R)), except:

• A Stop command does not reset the reference to zero. The reference is stored.

• When the drive restarts, the motor ramps up (at the selected acceleration rate) to the stored reference.

7 =

DI5U,6D – Same as above (DI3U,4D), except that DI5 and DI6 are the digital inputs used.

8 =

COMM – Defines the fieldbus as the reference source.

9 =

COMM+AI1 – Defines a fieldbus and analog input 1 (AI1) combination as the reference source. See Analog input

reference correction below.

10 =

COMM

*

AI1 – Defines a fieldbus and analog input 1 (AI1) combination as the reference source. See Analog input

reference correction below.

11 =

DI3U,4D(RNC) – Same as DI3U,4D(R) above, except that:

• Changing the control source (

EXT1 to EXT2, EXT2 to EXT1, LOC to REM) does not copy the reference.

12 =

DI3U,4D(NC) – Same as DI3U,4D above, except that:

• Changing the control source (

EXT1 to EXT2, EXT2 to EXT1, LOC to REM) does not copy the reference.

13 =

DI5U,6D(NC) – Same as DI5U,6D above, except that:

• Changing the control source (

EXT1 to EXT2, EXT2 to EXT1, LOC to REM) does not copy the reference.

14 =

AI1+AI2 – Defines an analog input 1 (AI1) and analog input 2 (AI2) combination as the reference source. See

Analog input reference correction below.

15 =

AI1

*

AI2 – Defines an analog input 1 (AI1) and analog input 2 (AI2) combination as the reference source. See

Analog input reference correction below.

16 =

AI1-AI2 – Defines an analog input 1 (AI1) and analog input 2 (AI2) combination as the reference source. See

Analog input reference correction below.

17 =

AI1/AI2 – Defines an analog input 1 (AI1) and analog input 2 (AI2) combination as the reference source. See

Analog input reference correction below.

20 =

KEYPAD(RNC) – Defines the control panel as the reference source.

• A Stop command resets the reference to zero (the

R stands for reset.).

• Changing the control source (

EXT1 to EXT2, EXT2 to EXT1) does not copy the reference.

21 =

KEYPAD(NC) – Defines the control panel as the reference source.

• A Stop command does not reset the reference to zero. The reference is stored.

• Changing the control source (

EXT1 to EXT2, EXT2 to EXT1) does not copy the reference.

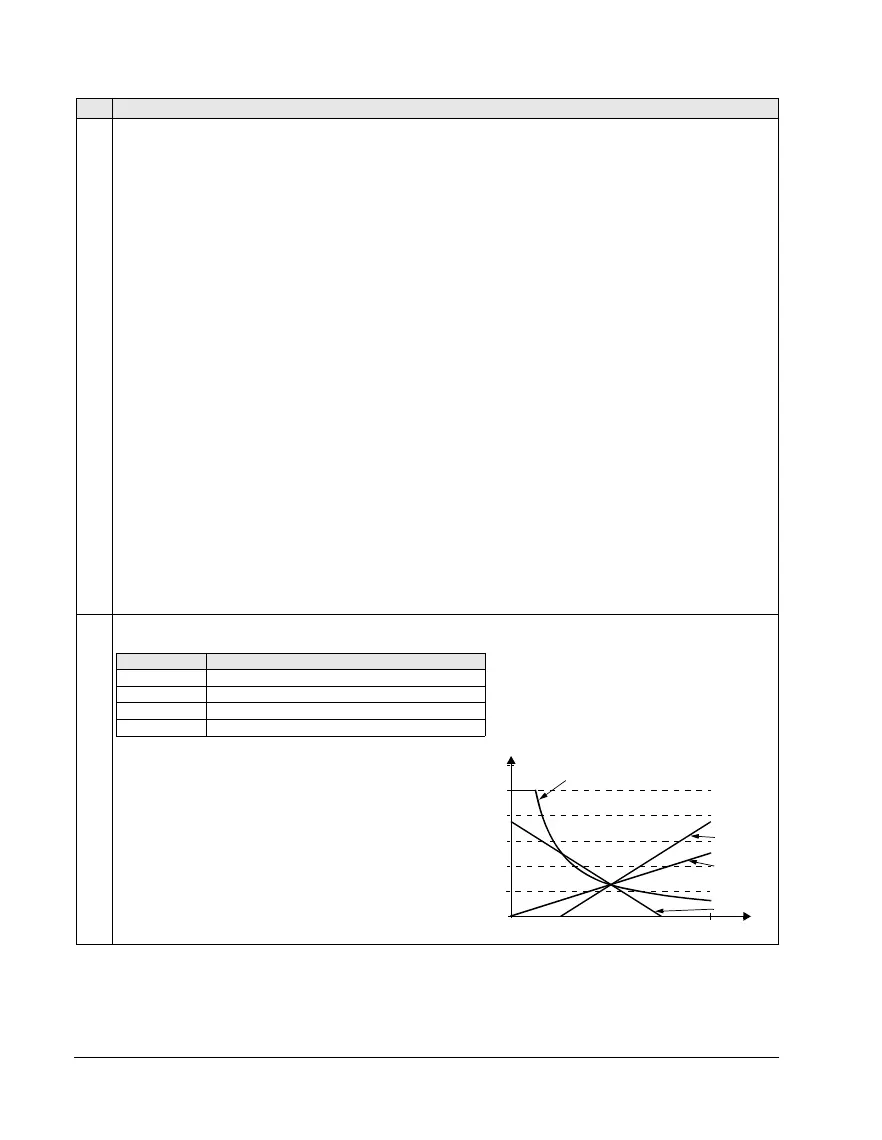

Analog input reference correction

Parameter values 9, 10 and 14…17 use the formula in the following table.

Where:

• C = Main reference value

( =

COMM for values 9, 10 and

=

AI1 for values 14…17).

• B = Correcting reference

( =

AI1 for values 9, 10 and

=

AI2 for values 14…17).

Example:

The figure shows the reference source curves for value

settings 9, 10 and 14…17, where:

• C = 25%.

• P 4012

SETPOINT MIN = 0.

• P 4013

SETPOINT MAX = 0.

• B varies along the horizontal axis.

Code Description

Value setting Calculation of the AI reference

C + B C value + (B value - 50% of reference value)

C

*

B C value · (B value / 50% of reference value)

C - B (C value + 50% of reference value) - B value

C / B (C value · 50% of reference value) / B value

120

100

80

60

40

20

0

0

100%

9, 14 (+)

16 (-)

10, 15 (

*

)

17 (/)

B

Loading...

Loading...