14 ACS550 User’s Manual

Installation

Motor compatibility

The motor, drive and supply power must be compatible:

Tools required

To install the ACS550 you need the following:

• screwdrivers (as appropriate for the mounting hardware used)

• wire stripper

• tape measure

• drill

• for installations involving ACS550-U1, frame sizes R5 or R6 and IP54 / UL type

12 enclosures: punch for creating conduit mounting holes

• for installations involving ACS550-U1, frame size R6: appropriate crimping tool

for power cable lugs. See section Power terminal considerations – R6 frame size

on page 269.

• mounting hardware: screws or nuts and bolts, four each. The type of hardware

depends on the mounting surface and the frame size:

Suitable environment and enclosure

Confirm that the site meets the environmental requirements. To prevent damage

prior to installation, store and transport the drive according to the environmental

requirements specified for storage and transportation. See section Ambient

conditions

on page 289.

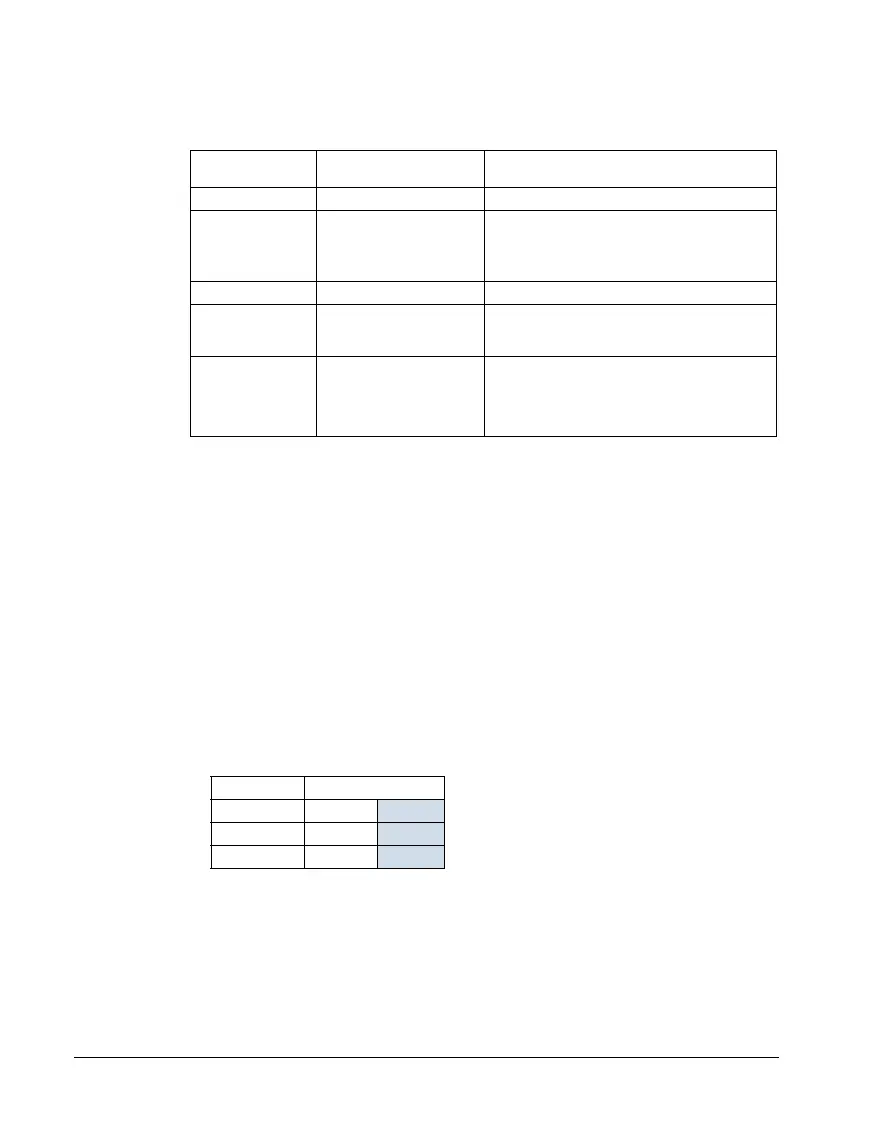

Motor

specification

Verify Reference

Motor type 3-phase induction motor –

Nominal current Motor value is within this

range: 0.2…2.0 · I

2hd

(I

2hd

= drive heavy duty

current)

• Type code label on drive, entry for Output I

2hd

,

or

• Type code on drive and rating table in chapter

Technical data on page 259.

Nominal frequency 10…500 Hz –

Voltage range Motor is compatible with

the ACS550 voltage range.

208…240 V (for ACS550-X1-XXXX-2) or

380…480 V (for ACS550-X1-XXXX-4) or

500…600 V (for ACS550-U1-XXXX-6)

Insulation 500…600 V drives: Either

the motor complies with

NEMA MG1 Part 31, or a

du/dt filter is used between

the motor and drive.

For ACS550-U1-XXXX-6

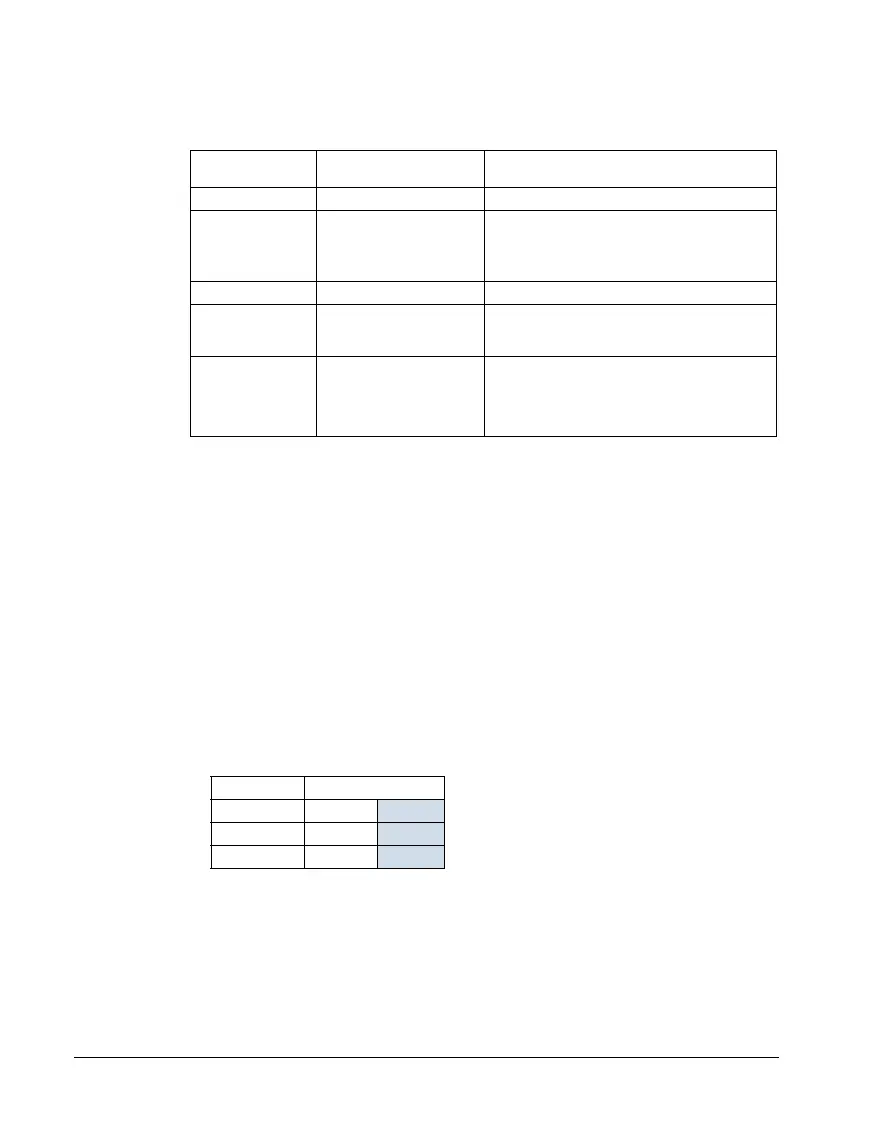

Frame size Mounting hardware

R1…R4 M5

#10

R5 M6

1/4 in

R6 M8

5/16 in

Loading...

Loading...