ACS550 User’s Manual 267

Technical data

• Power cable shields are suitable for use as equipment grounding conductors only

when the shield conductors are adequately sized as required by safety

regulations.

• In multiple drive installations, do not connect drive terminals in series.

Corner grounded TN systems

WARNING! Do not attempt to install or remove EM1, EM3, F1 or F2 screws while

power is applied to the drive’s input terminals.

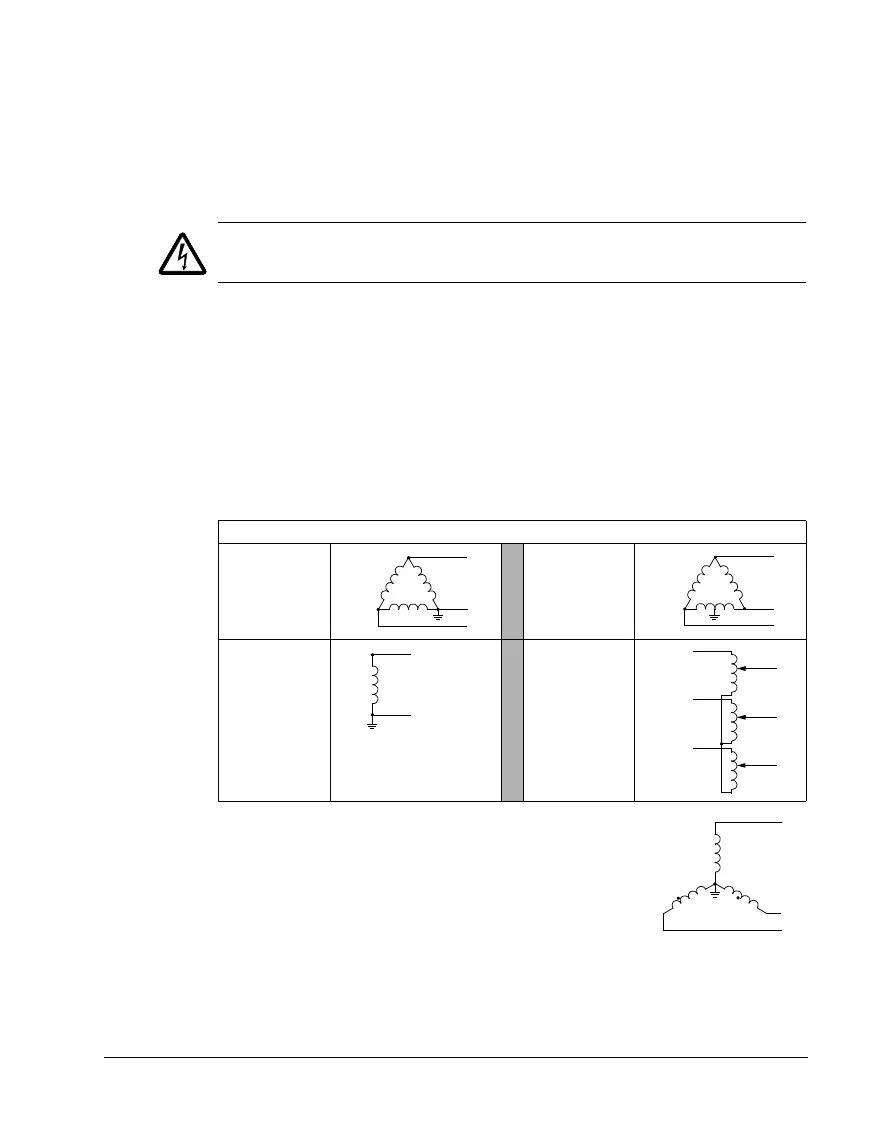

Corner grounded TN systems are defined in the following table. In such systems,

disconnect the internal ground connection by removing the screws (do this also if the

grounding configuration of the system is unknown):

• ACS550-01, frame sizes R1…R4: Remove both the EM1 and EM3 screws (see

section Power connection diagrams on page 20).

• ACS550-U1, frame sizes R1…R4: Remove the EM1 screw –

drive is shipped with

EM3 removed (see section Power connection diagrams on page 20).

• Frame sizes R5…R6: Remove both the F1 and F2 screws (see section Power

connection diagrams, page 21).

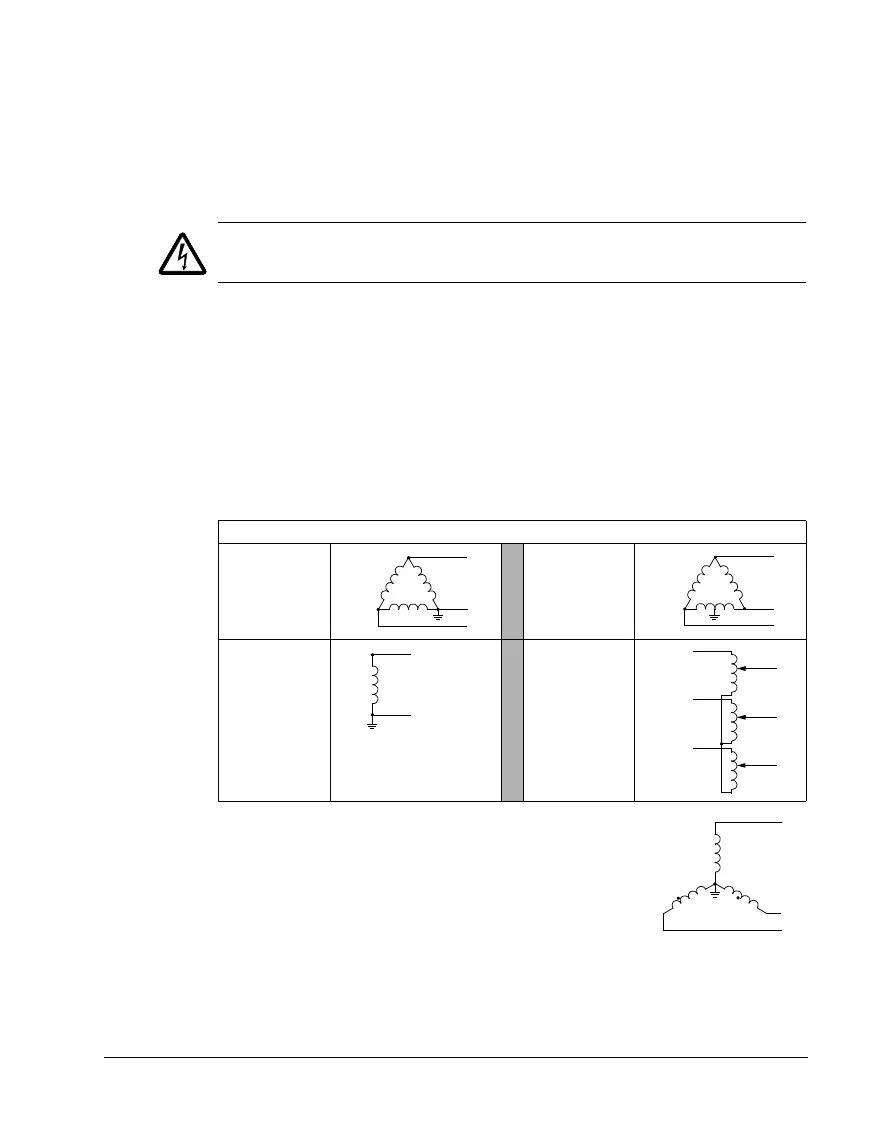

The screws (M4×16) make an internal ground connection that

reduces electro-magnetic emission. Where EMC (electro-

magnetic compatibility) is a concern, and the system is

symmetrically grounded, the screws may be installed. For

reference, the diagram on the right illustrates a symmetrically

grounded TN system.

Corner grounded TN systems – EM1, EM3, F1 and F2 must be out

Grounded at the

corner of the

delta

Grounded at the

mid point of a

delta leg

Single phase,

grounded at an

end point

Three phase

“Variac” without

solidly grounded

neutral

L1

L2

L3

L1

L2

L3

L1

N

L1

L1

L2

L2

L3

L3

L1

L2

L3

Loading...

Loading...