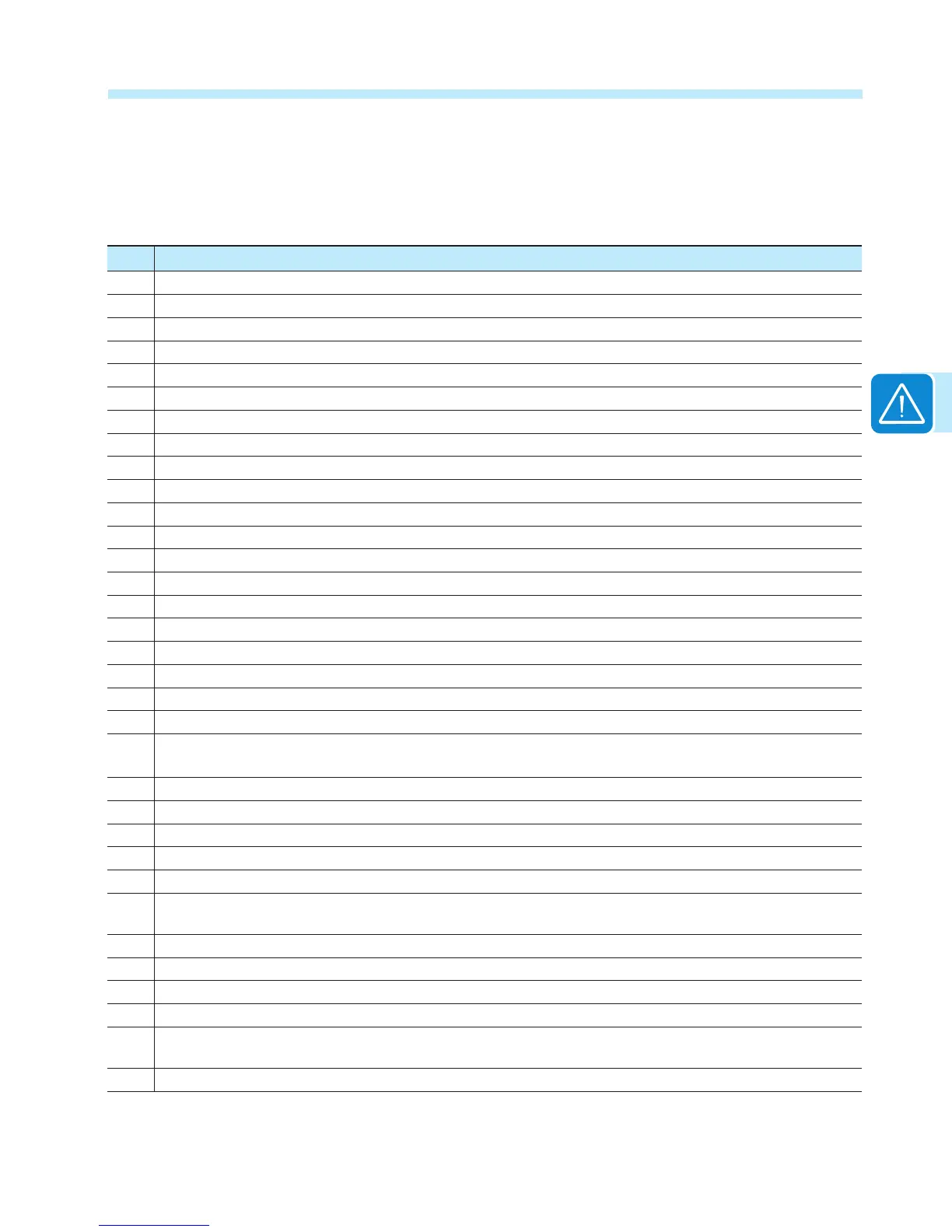

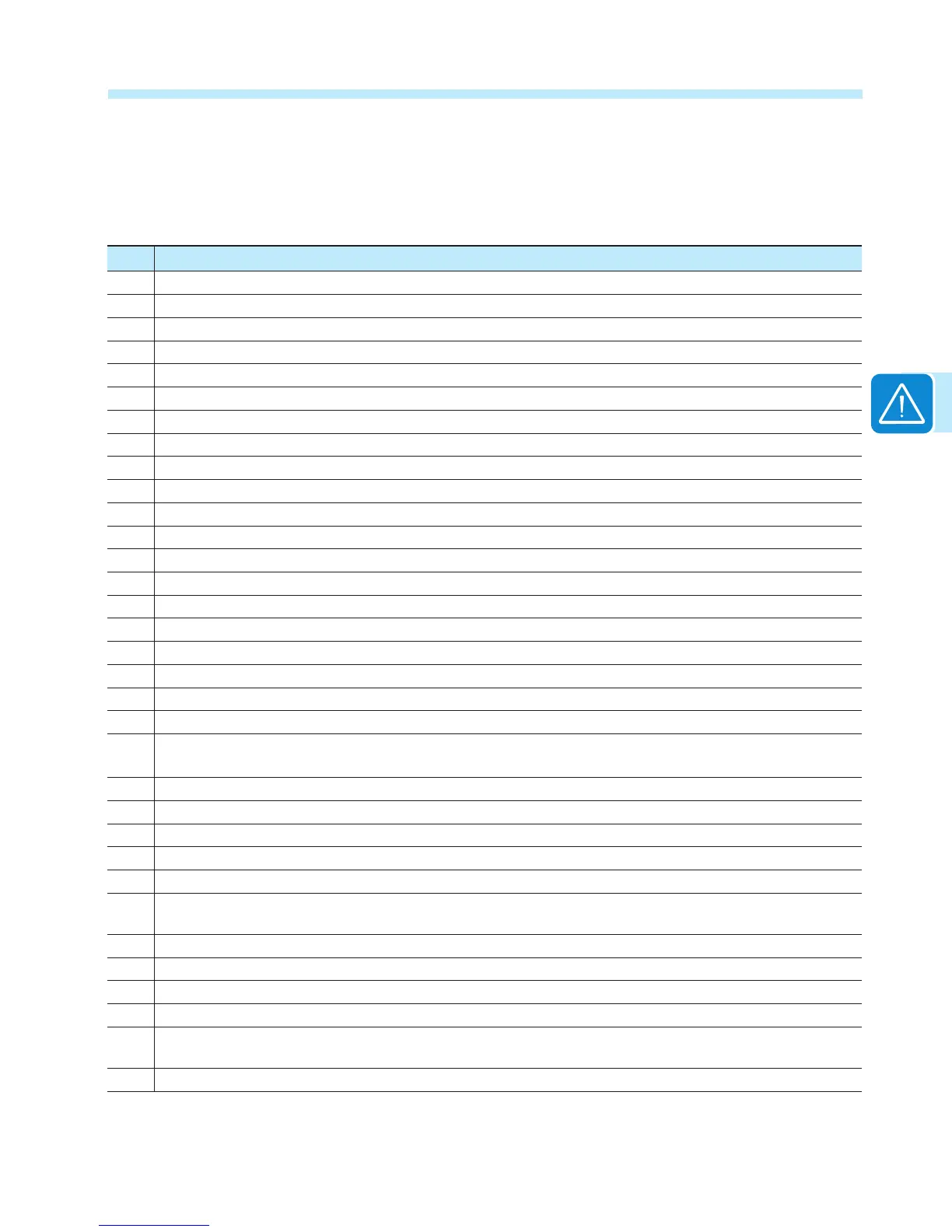

Wiring box components

There are four models of the wiring box available for either the 20.0 kW or 27.6 kW versions. Each model is

available with or without arc fault detection (AFD). The major differences between the wiring box layouts are

illustrated after the descriptions in the table below.

Ref. Description

01 Mounting bracket

02 Wiring box

03 Inverter

04 Coupling connector cover

05 Clamp screw

06 Optional lifting handles

07 Connector screws

08 Wiring box front cover

09 Communication board

10 Service cable and communications opening with plastic threaded plug, Trade size 1/2“

11 DC cable openings with plastic threaded plug *, Trade size 1”, 1 ½”

12 Solid copper jumper for paralleling inputs

13 DC terminal block (-S version)

14 DC disconnect switch handle

15 Class II DC surge protection (-S1, -S1A, -S1B versions)

16 AC cable opening with plastic threaded plug, Trade size 1”

17 AC terminal block

18 AC board (located behind 19 in –S1A and behind 20 in –S1B )

19 Class II AC surge protection (-S1A version)

20 Fused AC disconnect switch (-S1B version)

21 Anti-condensation valve (eliminates condensation buildup)

DO NOT REMOVE!

22 DC fuse holders (-S1, -S1A, -S1B versions)

23 Display

24 LED panel

25 Keypad

26 Heatsink

27 Equipment ground conductor (EGC) busbar (DC equipment grounding bar is common with the AC side; NO interconnecting

jumpers are required)

28 AC ground terminal

29 Arc fault detection (AFD) board

30 Positive input paralleling terminal blocks (use with non-AFCI versions only)

31 Negative input paralleling terminal blocks (use with non-AFCI versions only)

32 Bottom locking tab for securing mounting bracket to wall; can also be used as exterior grounding electrode conductor (GEC)

connection

33 Hole on wiring box cover and wiring box chassis used to insert a padlock

* If a 2” conduit is needed for DC cable, the DC cable entries can be punched to accommodate these using a knockout hole punch in

location of existing knockouts.

Loading...

Loading...