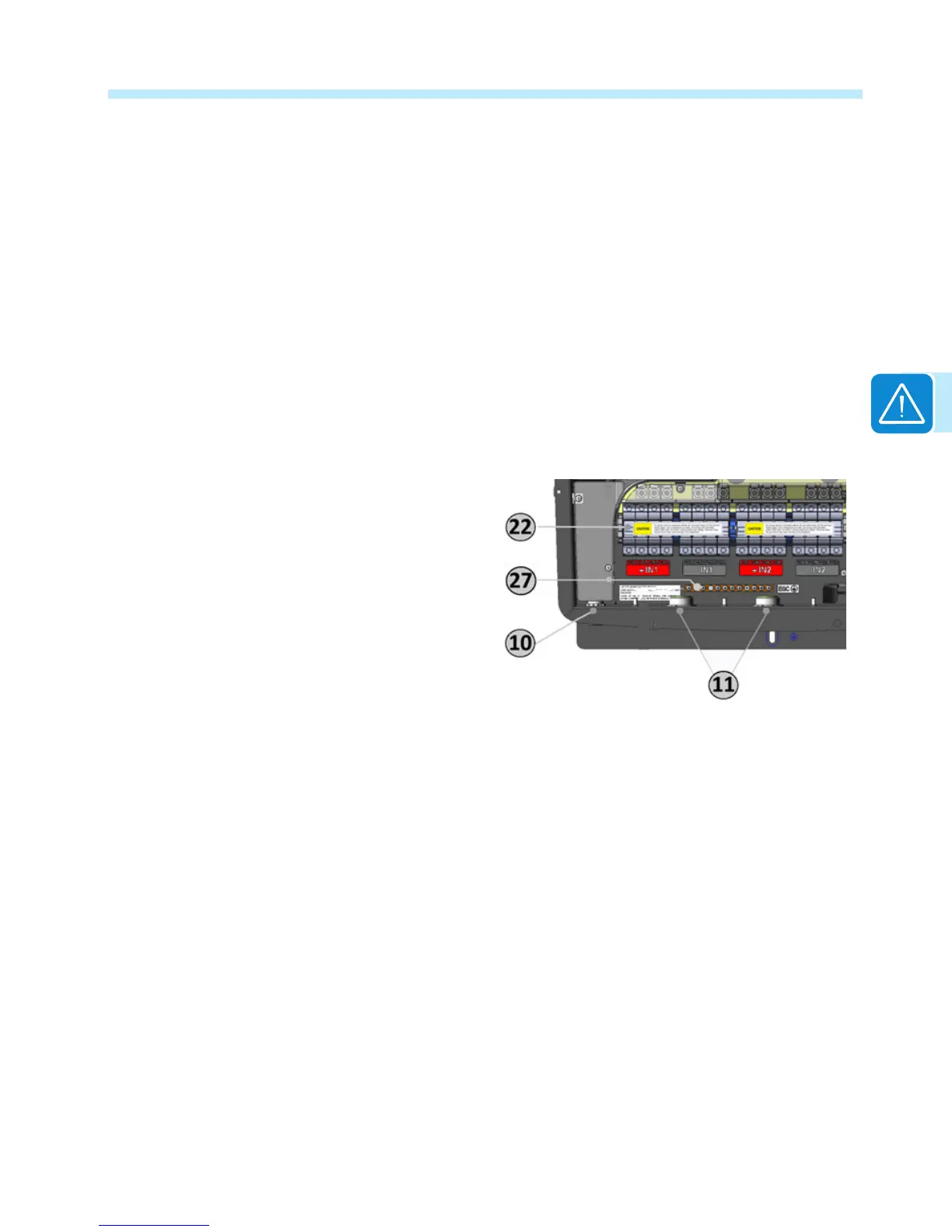

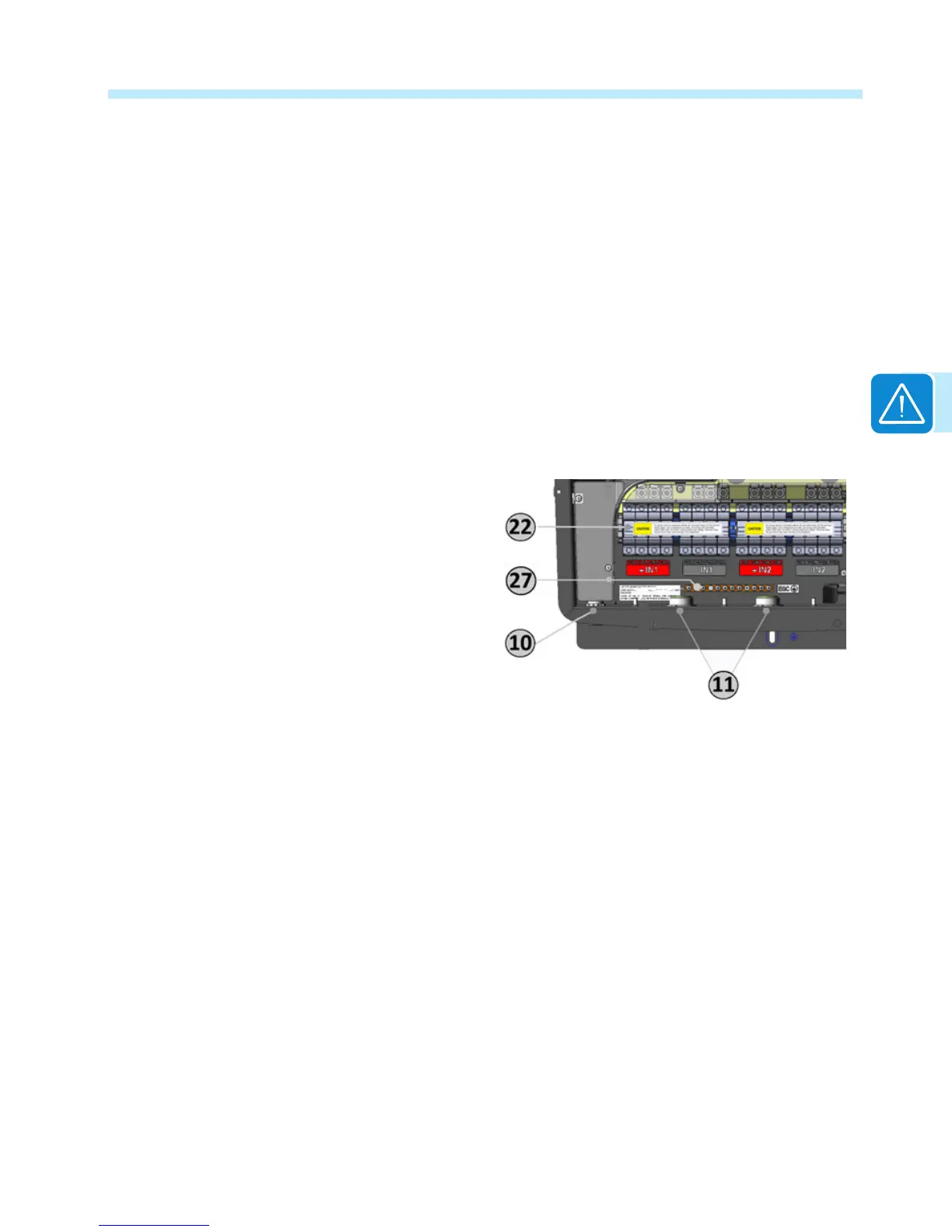

Connection of DC inputs -S1, –S1A, and -S1B models

Remove the threaded plastic plug and nut from the DC cable opening 11 and insert the

appropriate conduit tting. Tighten to the chassis to ensure NEMA 4X compliance.

After reading the two CAUTION labels in place on the DC fuse blocks 22, remove them and then

open all fuse holders before connecting the PV strings.

Connect conductors to the correct input channel (if using the parallel conguration, either input

channel is acceptable).

The acceptable wire size range is from 12 AWG to 6 AWG, copper conductors only; refer to

local code for appropriate wire size. Fuse holders have screw terminals and the torque depends

on wire size. For wire sizes 10 AWG and larger, tighten to 30 in-lbs (3.4 Nm) torque.

Test each string for polarity and

voltage using a voltmeter (rated

2000V min.). After conrming

correct polarity and voltage on all

strings, close all fuse holders.

Connect any Equipment Grounding

conductors in the raceway to the

EGC busbar 27. The DC equipment

grounding bar is common with the

AC side and no other interconnecting

jumpers or the like are required.

String protection -S1, -S1A, and –S1B models

The -S1, -S1A and -S1B versions of the TRIO wiring box are provisioned with 30A rated UL

Listed/CSA certied fuse holders, supplied with 15A, 1000V DC rated fuses.

To determine the correct fuse value to use with a specic PV array, refer to the PV module

documentation and the National Electrical Code 690.8 and 690.9 or your local electrical code.

Loading...

Loading...