SMD17E2 SPECIFICATIONS

SMD17E2 User Manual

ADVANCED MICRO CONTROLS INC.

16

Indexer Functionality (continued)

Stall Detection with SMD17E2 Units

Stall Detection is one of the additional features available to you when you order an encoder option on an

SMD17E2. When Stall Detection is enabled, the SMD17E2 monitors the encoder for position changes,

regardless of whether or not a move is in progress. If the error between the encoder position and the motor

position exceeds forty-five degrees, the SMD17E2 responds in the following manner:

The stall is reported in the network input data.

The motor position becomes invalid. (The machine must be homed or the motor position preset before

Absolute moves can be run again.

If a move was in progress, the move is stopped.

Note that a move does not have to be in progress for stall detection to be useful. As described later in this

chapter, there is an auxiliary power pin that powers the electronics of an SMD17E2 but does not power the

motor. The primary use of this feature is to keep the unit on the network while power is removed from the

motor. When using the DCPower

AUX

pin, the SMD17E2 cannot sense when power has been removed from

the DCPower

MAIN

pin. By enabling stall detection, the SMD17E2 can notify the system if the motor shaft

moves more than forty-five degrees while power is removed from the motor.

Driver Functionality

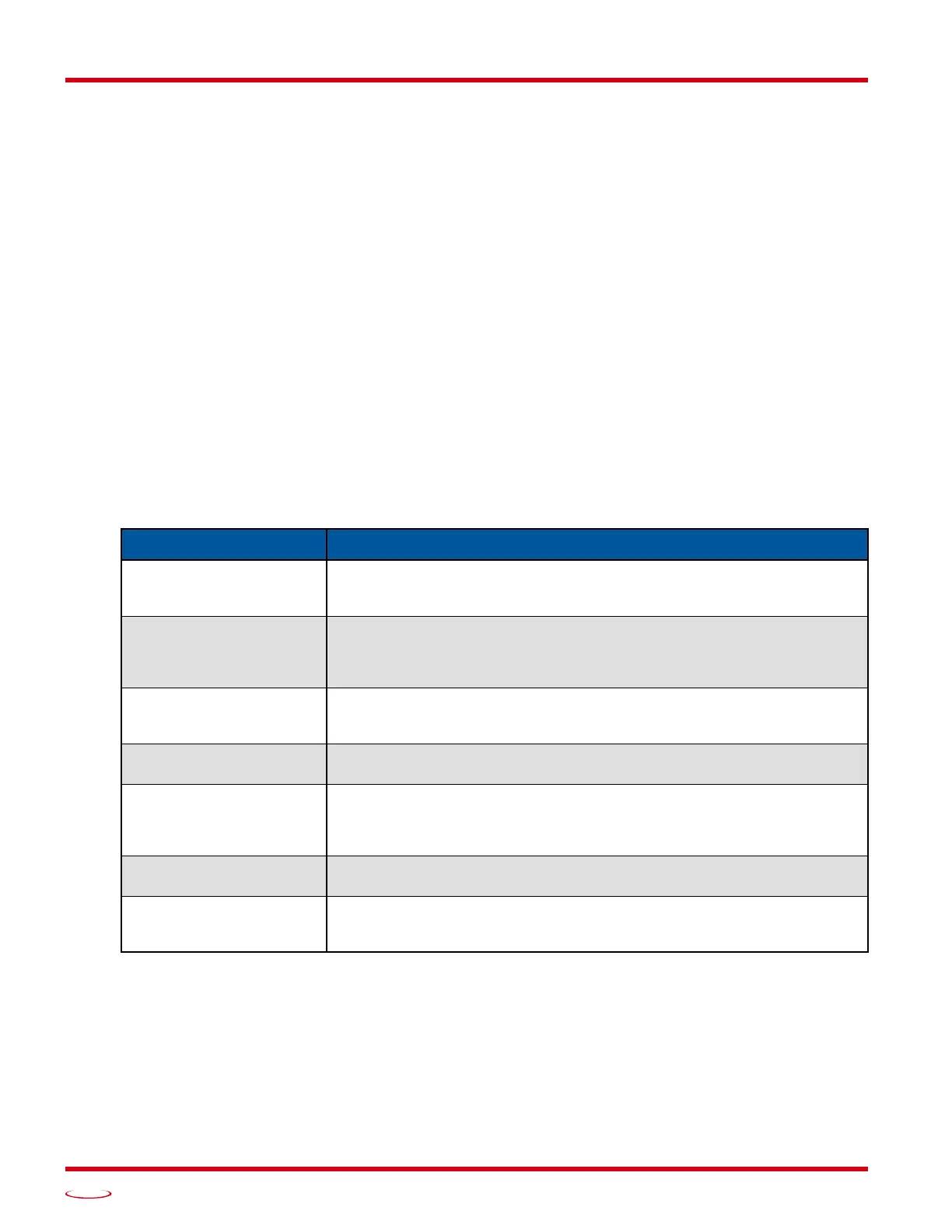

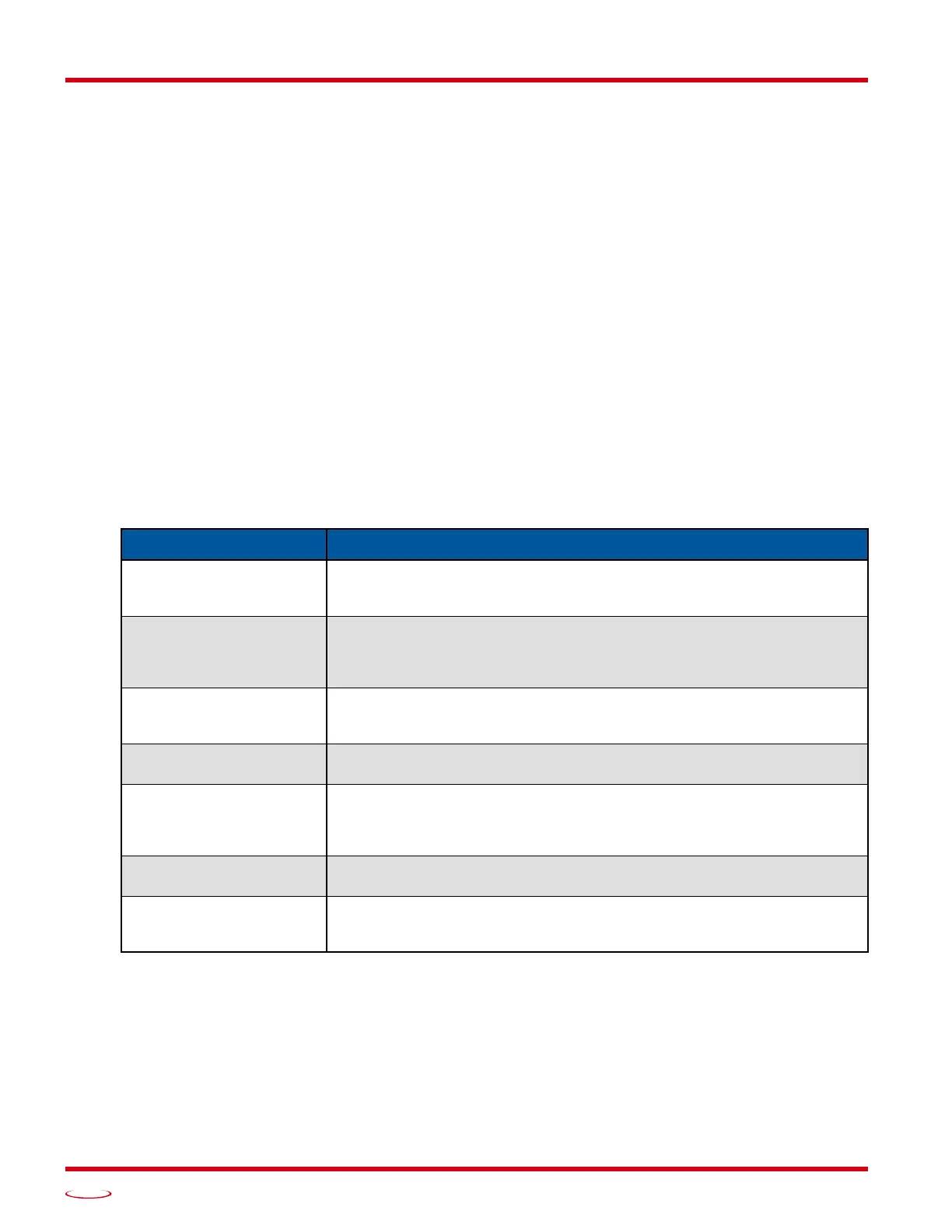

This table summarizes the features of the stepper motor driver portion of an SMD17E2.

Table R1.2 Driver Functionality

Feature Benefits

RMS Current Control

RMS current control give an SMD17E2 the ability to drive the motor at its

fully rated power regardless of the programmed steps per turn. There is no

reduction in power when microstepping that may occur with other drivers.

Programmable

Motor Current

RMS current supplied to the motor can be programmed from 0.1 to 2.0

amps in 0.1 amp increments. Reducing the motor current to the minimum

needed for your application will significantly reduce the motors operating

temperature

Programmable Idle

Current Reduction

Extends motor life by reducing the motor current when motion is not

occurring. This extends the life of the motor by reducing its operating

temperature.

Programmable

Motor Steps/Turn

Allows you to scale your motor count to a real world value. (counts per

inch, counts per degree, etc.)

Anti-Resonance Circuitry

This feedback circuitry and algorithm gives the SMD17E2 the ability to

modify motor current waveforms to compensate for mechanical resonance

in your system. This will give you smooth performance over the entire

speed range of the motor.

Over Temperature

Detection

An SMD17E2 sets a warning bit in the network data when the temperature

of the unit approaches its safe operating threshold.

Over Temperature

Protection

Protects your SMD17E2 from damage by removing power from the motor

if the internal temperature of the driver exceeds the safe operating thresh

-

old of 203°F/95°C.

Loading...

Loading...