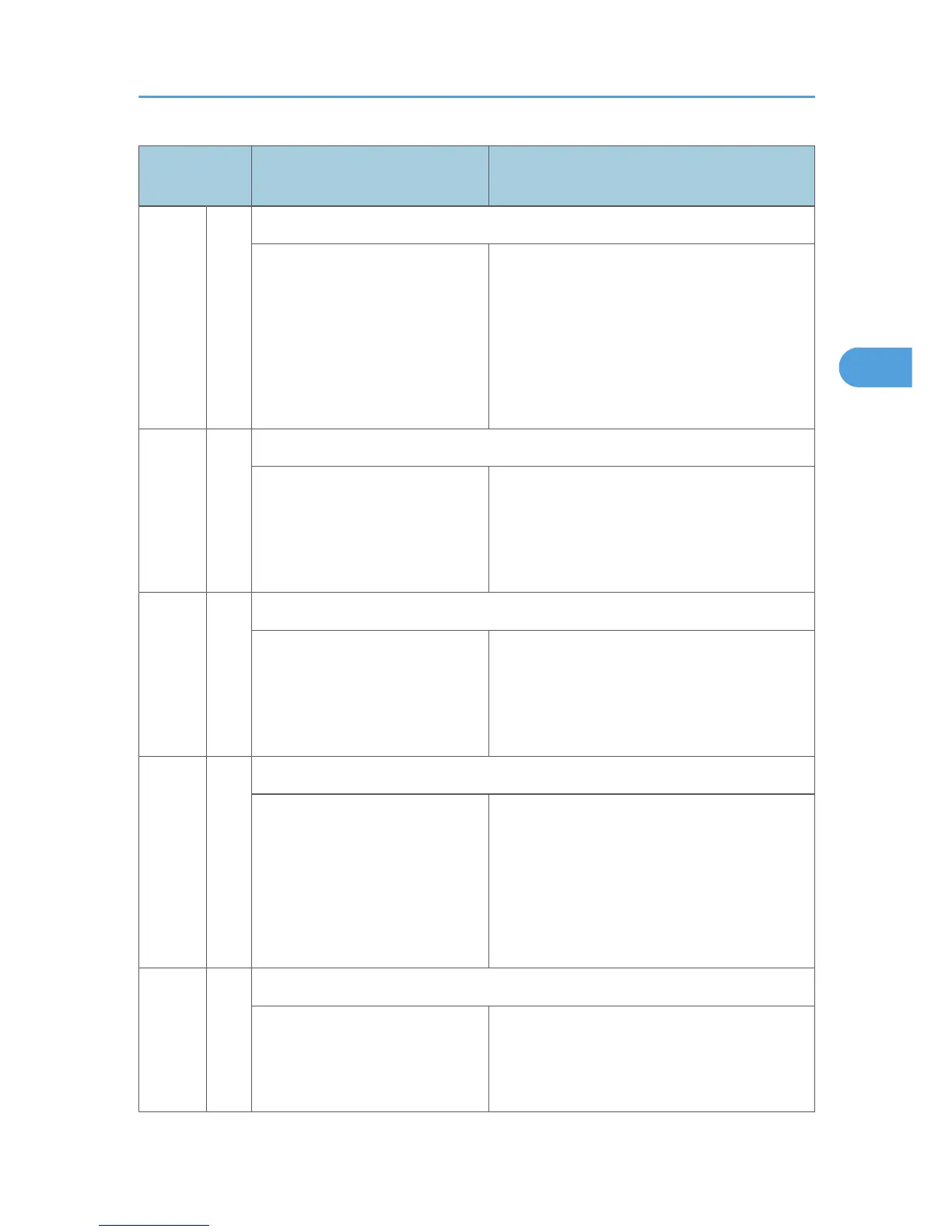

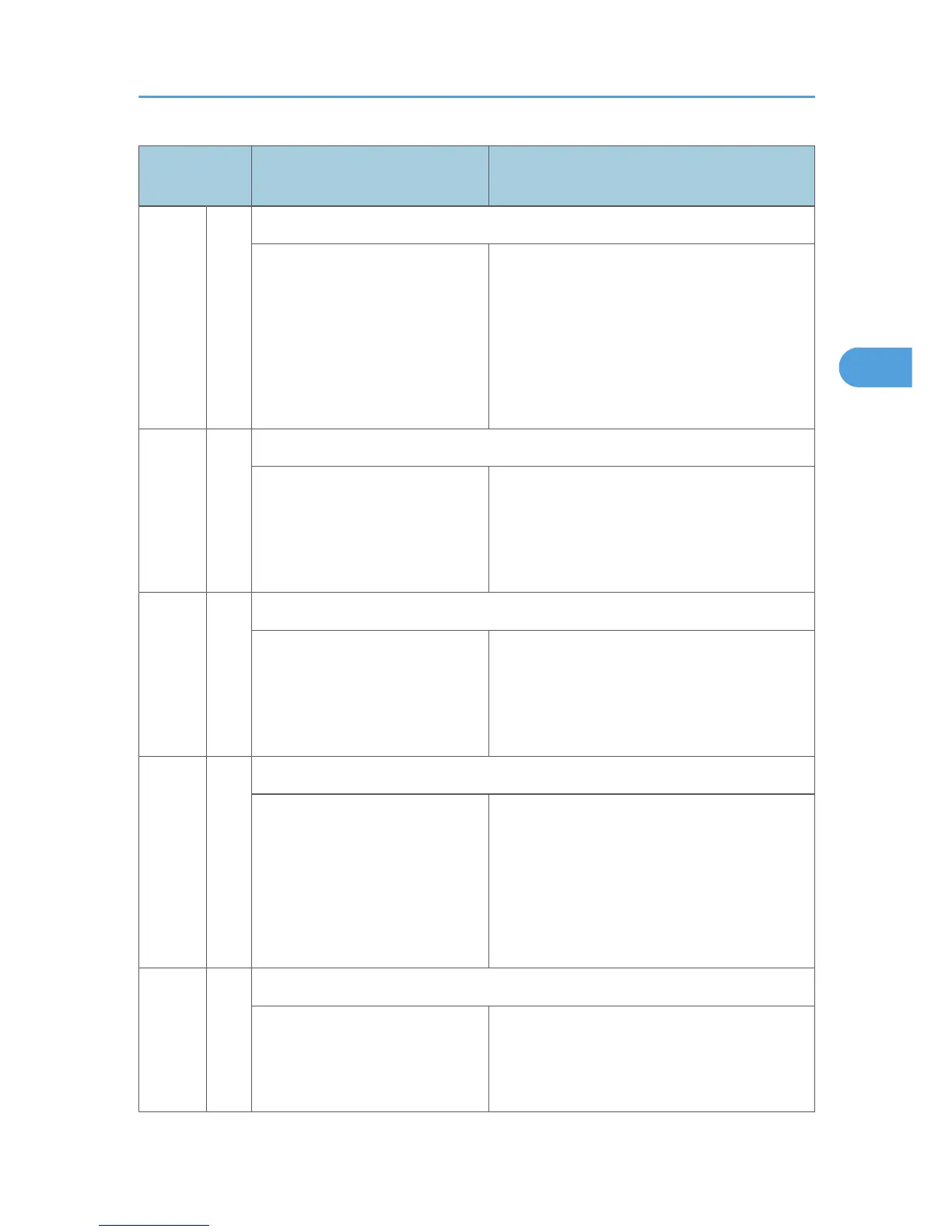

No.

Definition

Symptom Possible Cause

392 B

TD sensor initial setting error

TD sensor initial setting is not

performed correctly.

ID sensor defective

No developer

Drum does not turn

Development roller does not turn

Poor connection of the PCU

The voltage is not applied to charge roller

401 B

Transfer roller leak error 1

A current leak signal for the transfer

roller is detected.

A current feedback signal for the

transfer roller is not detected.

High voltage supply board defective

Poor connection of the PCU

Transfer/separation unit set incorrectly

Transfer roller damaged

402 B

Transfer roller leak error 2

A current leak signal for the transfer

roller is detected.

A current feedback signal for the

transfer roller is not detected.

High voltage supply board defective

Poor connection of the PCU

Transfer/separation unit set incorrectly

Transfer roller damaged

500 B

Main motor lock

A main motor lock signal is not

detected for more than 7

consecutive checks (700 ms) after

the main motor starts to rotate, or

the lock signal is not detected for

more than 7 consecutive checks

during

rotation

after the last signal.

Too much load on the drive mechanism

Main motor defective

541 A

Fusing thermistor open (center)

The fusing temperature detected by

the thermistor

is below 71°C and is

not corrected after the main power

switch is turned on.

Fusing thermistor defective or out of position

Power supply board defective

Loose connectors

Service Call Conditions

23

Loading...

Loading...