Routine Maintenance: Inlets

Maintaining a purged packed inlet

Released: March 2004 6850 Series II GC User Information page 142 of 256

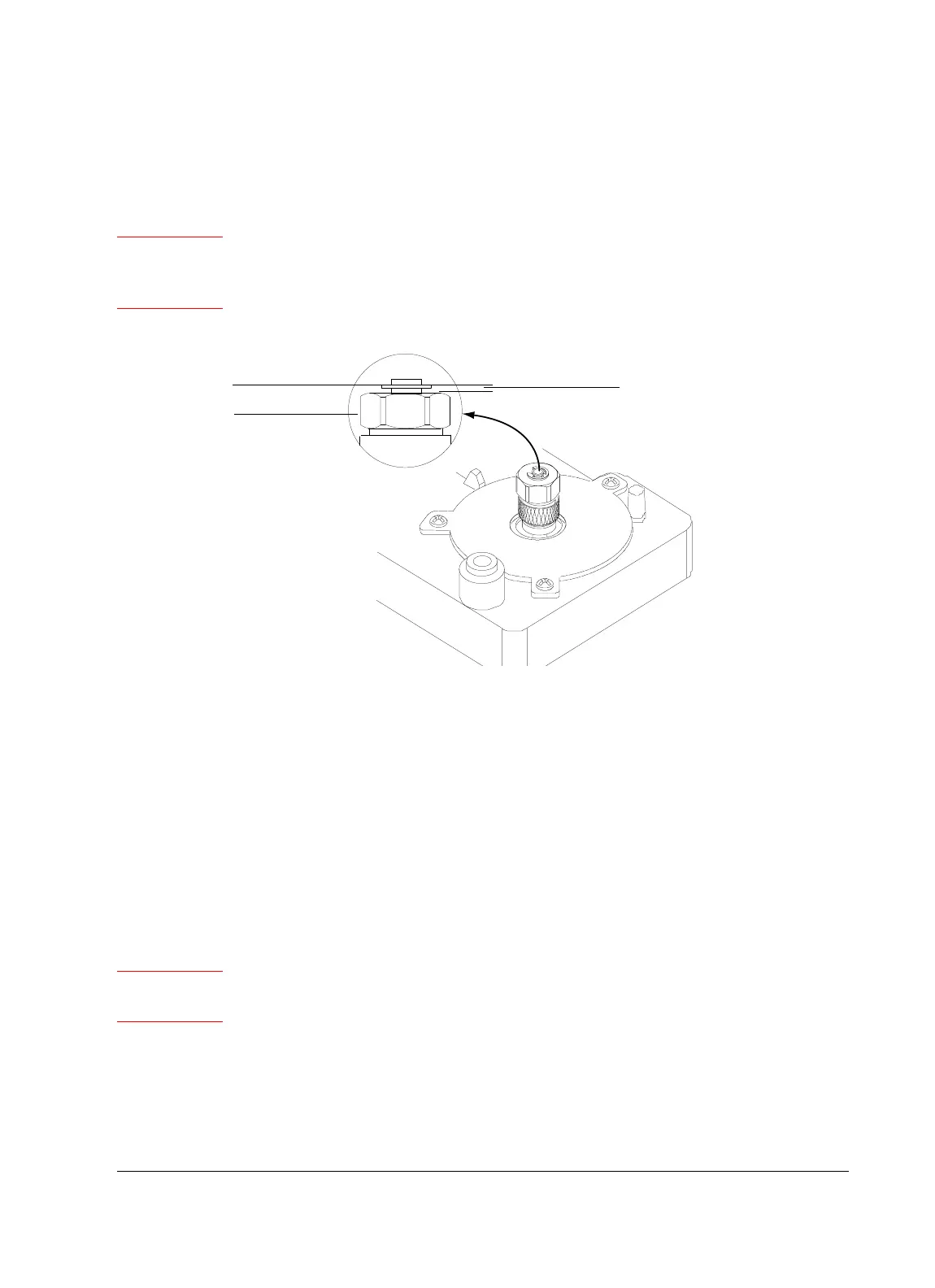

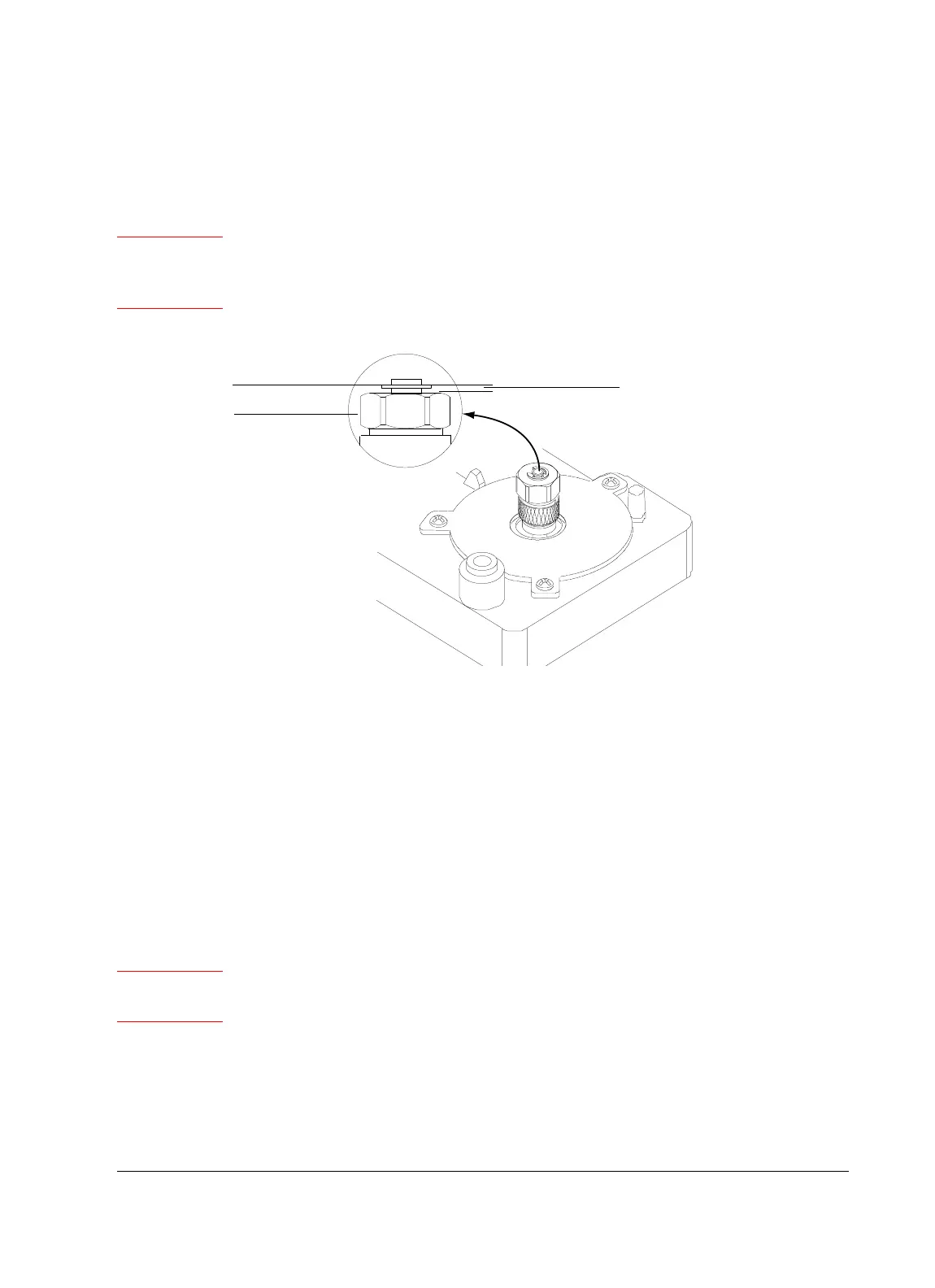

6. Replace the septum retainer nut, tightening it finger-tight until the C-ring is

approximately 1 mm above the nut. Avoid overtightening

Caution Do not overtighten the nut. Over-tightening over-compresses the septum,

which could cause premature failure and pieces of septum to contaminate the

inlet.

7. Restore normal operating conditions.

Changing the O-ring

You will need to change the O-ring periodically because it wears out and

becomes a source of leaks in the inlet. To determine if the O-ring leaks,

perform the leak test presented later in this chapter.

O-rings contain plasticizers that give them elasticity. The O-ring seals the top of

the inlet and the inlet base. However, at high temperatures the plasticizers

bake out, and the O-rings become hard and are unable to create a seal (this is

referred to as “taking a set”). If you operate the inlet at high temperatures, you

will probably need to replace the O-ring frequently.

Warning Be careful! The oven and/or inlet may be hot enough to cause burns.

If the inlet is hot, be sure to wear gloves to protect your hands.

C-ring

Septum retainer nut

1 mm between

nut and C-ring

Loading...

Loading...