Introduction

Gas connections

Released: March 2004 6850 Series II GC User Information page 16 of 256

Column oven and column

Use a Control Module or ChemStation/Cerity Chemical to program up to six

temperature ramps, separated by hold periods.

To control the behavior of the carrier gas in the column, specify constant or

ramped flow, or constant or ramped pressure. The GC maintains this behavior

for the entire run, even with temperature programming. The flow modes are

available only if the column is defined.

Automation

Use a Control Module or ChemStation/Cerity Chemical to:

• Set injector control parameters (sample size, syringe size, number of

sample pumps, and other injection parameters)

•Build a run table to execute commands at specified times after injection

•Build a clock table to execute commands at specified times of day

• Create a sequence to analyze a set of samples (vials or stream selection

valve positions) by the active method

• Inject using a gas or liquid sampling valve

• Control a multiposition stream selection valve

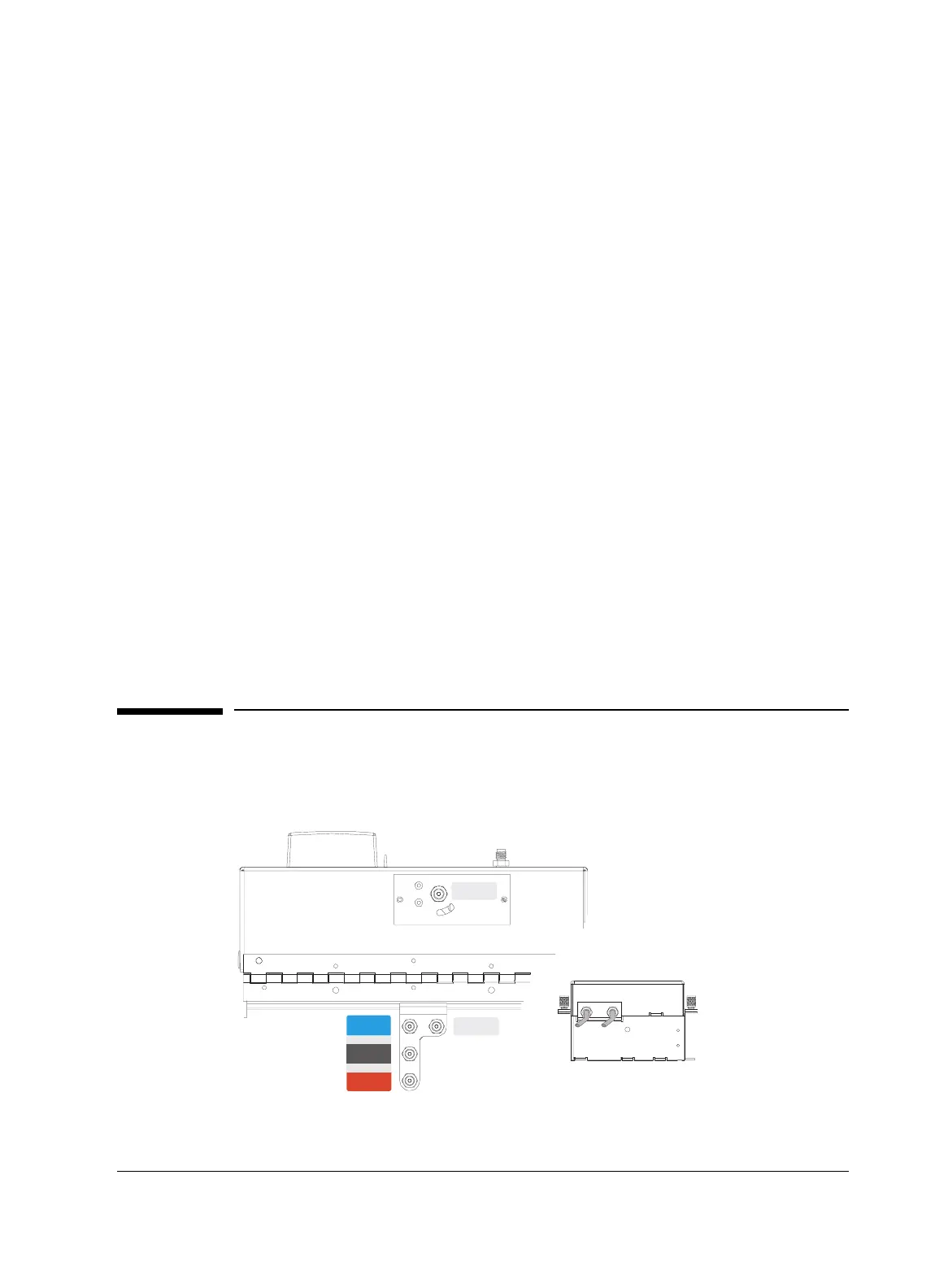

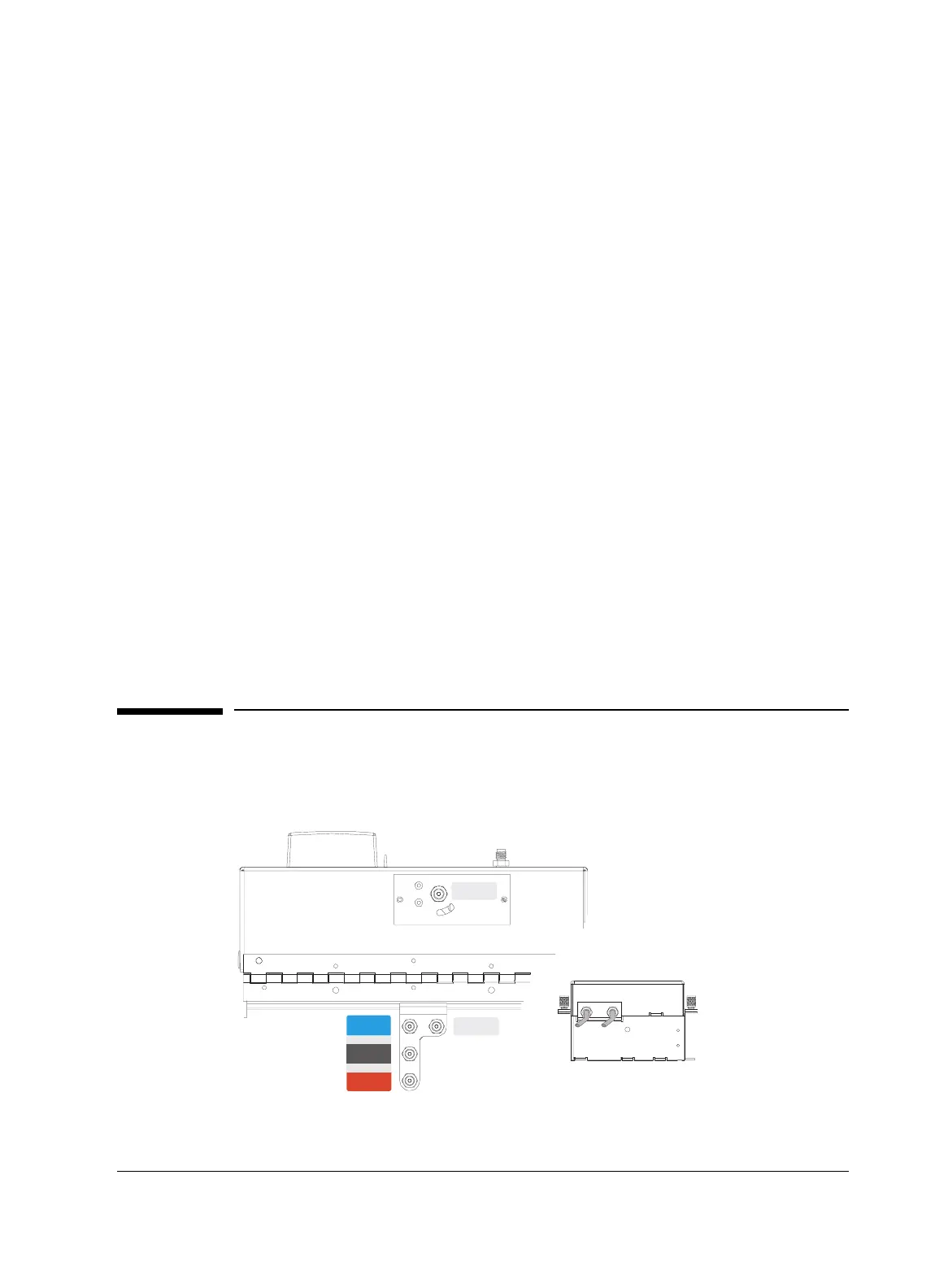

Gas connections

All gas connections are made on the mainframe and lid back panels as shown

in Figure 2.

Figure 2. Gas connections

Actuator

Air

Carrier

Gas

Detector

Air

Reference/

Make-up

Gas

Detector

H2

SAMPLE

OUT

SAMPLE

IN

Loading...

Loading...