Installation

Configuration

Released: March 2004 6850 Series II GC User Information page 252 of 256

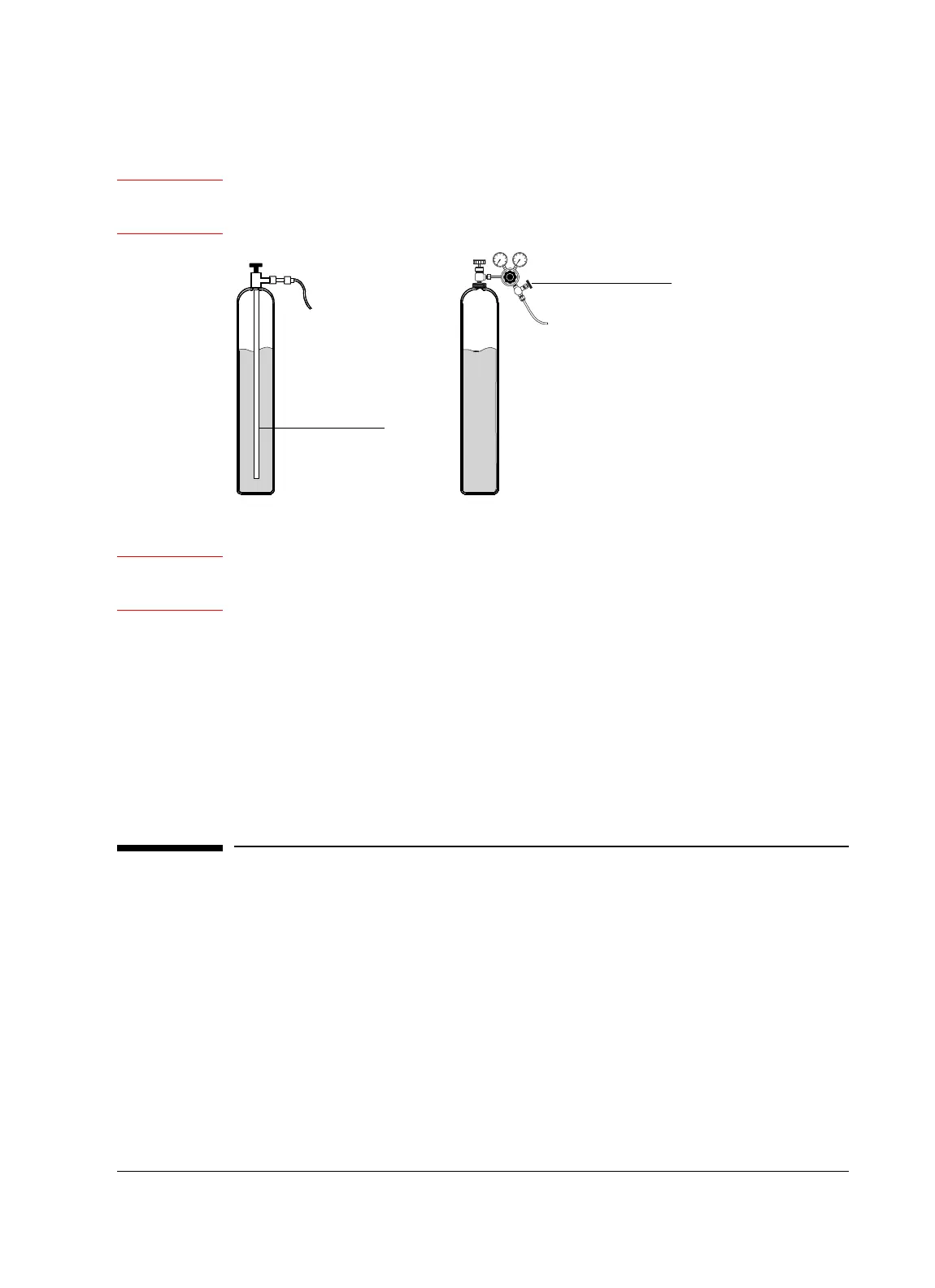

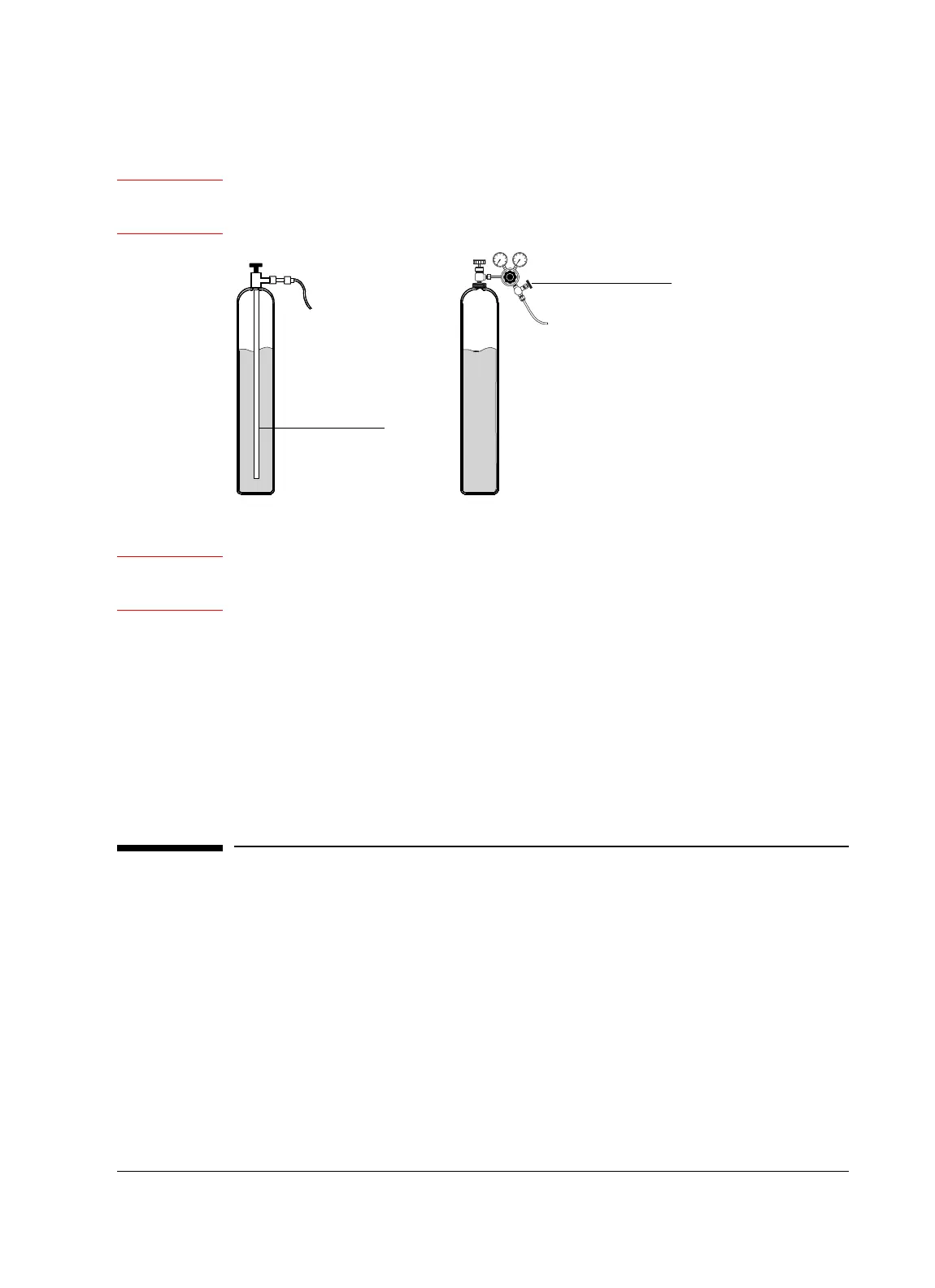

Caution Do not install a pressure regulator on the CO

2

tank, as vaporization and cooling

would occur in the regulator instead of the oven.

Warning All fittings and tubing should be stainless steel. The pressure inside a liquid

CO

2

tank can be as high as 1000 psi.

1. Connect a CGA 320 to 1/4-inch male NPT fitting to the tank followed by a

Swagelok part no. SS-200-7-4 1/4-inch female NPT to 1/8-inch tube fitting.

2. Connect the tank to the cryogenic filter inlet with 1/8-inch diameter heavy-

wall stainless steel tubing. The tubing may be up to 50 feet long.

Allow some slack in the line to make movement of the tank or GC easier.

Coil and fasten the ends of the tubing to keep it from “whipping” if it

breaks.

Configuration

In order to properly control instrument gas flows and temperatures, and to

provide proper functionality for valves, the instrument maintains a list of

manually-configured settings. These include carrier and detector gas types,

valve types (if installed), and the time and date. Agilent sets these parameters

at the factory. In general, if using the same gases as used for the detector

checkout method, no further configuration is needed.

Dip tube

Correct Incorrect

Pressure regulator

Loading...

Loading...