127

REPLACEMENT OF MAIN COMPONENTS

3. Check that no refrigerant is left in the main unit, and

perform the following work.

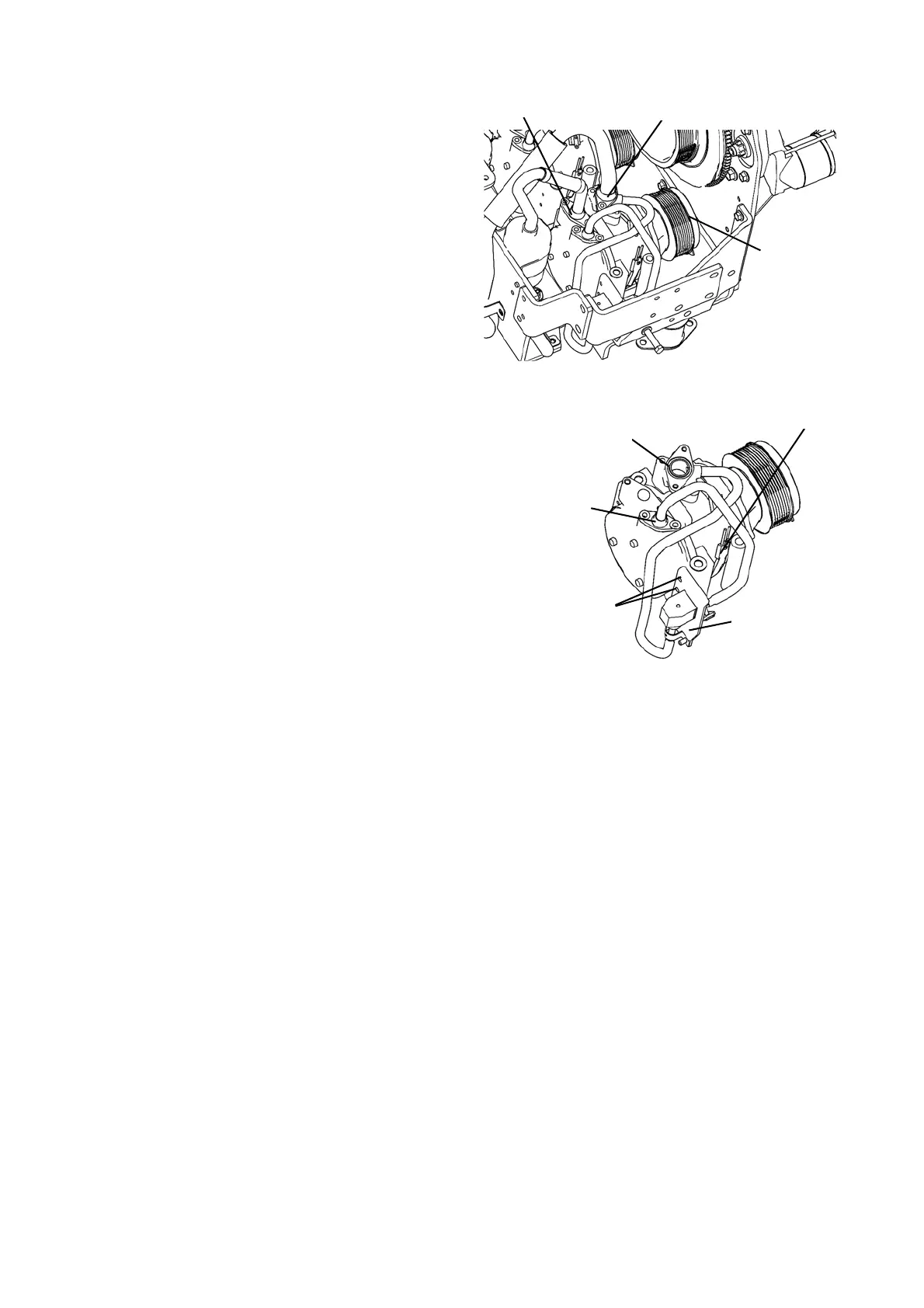

1) Turn the compressor pulley (clutch plate as for No.

2 compressor) a few turns by hand.

2) Loosen each 2 bolts of intake (upper side) and dis-

charge ports.

3) Disconnect the oil tube between the oil tank and

compressor at the oil tank side. (Do not disconnect

the oil tube from the compressor at this time.)

4) Dismount the compressor from the bracket.

NOTE) Take care so that the flanges (o-ring contact

surfaces) of each port are not damaged.

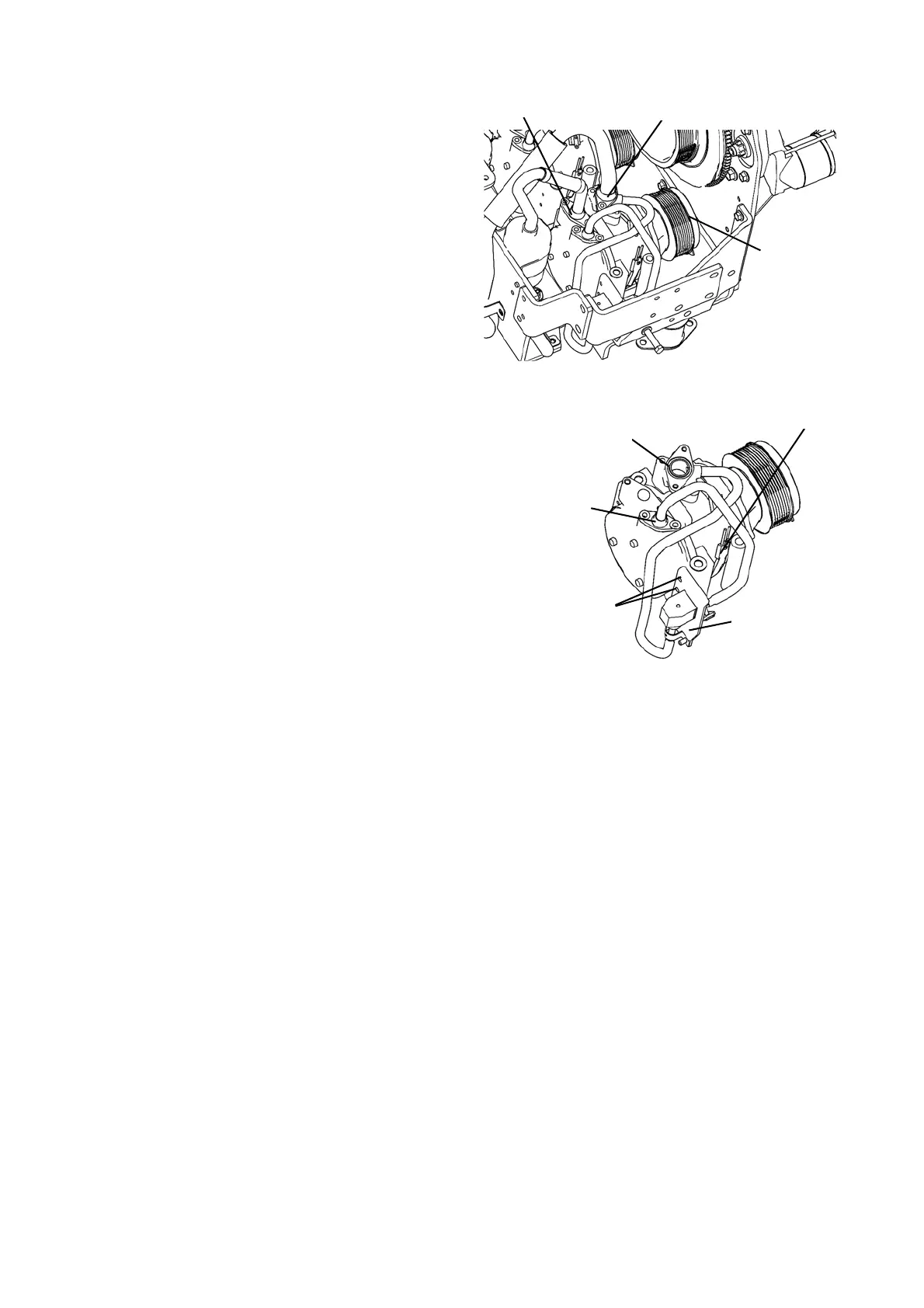

4. Place the removed compressor on the table approx-

imately 4 inch (100 mm) high, and perform the

following work.

1) Disconnect the oil tube from the compressor.

2) Unscrew each 2 bolts of electromagnetic compres-

sor capacity valve and intake ports.

3) Unscrew 2 bolts to remove the electromagnetic

compressor capacity valve with the stay.

4) Remove the compressor heater from the compres-

sor.

Pulley

Discharge port

Intake port

Compressor heater

Bolts

Stay

Intake port

Electromagnetic

compressor

capacity port

Loading...

Loading...