AKYAPAK-AHS-UserManual-2019.03.11

Sometimes, some errors may occur in the bending process. These are divided into two:

1) Barrel error

2) Reverse barrel error

In fact, machines are produced by avoiding these errors.

Taper of the rolls are calculated, so they can provide a good performance even in the highest

thickness. However, materials with excessive thickness or thinness may cause these errors.

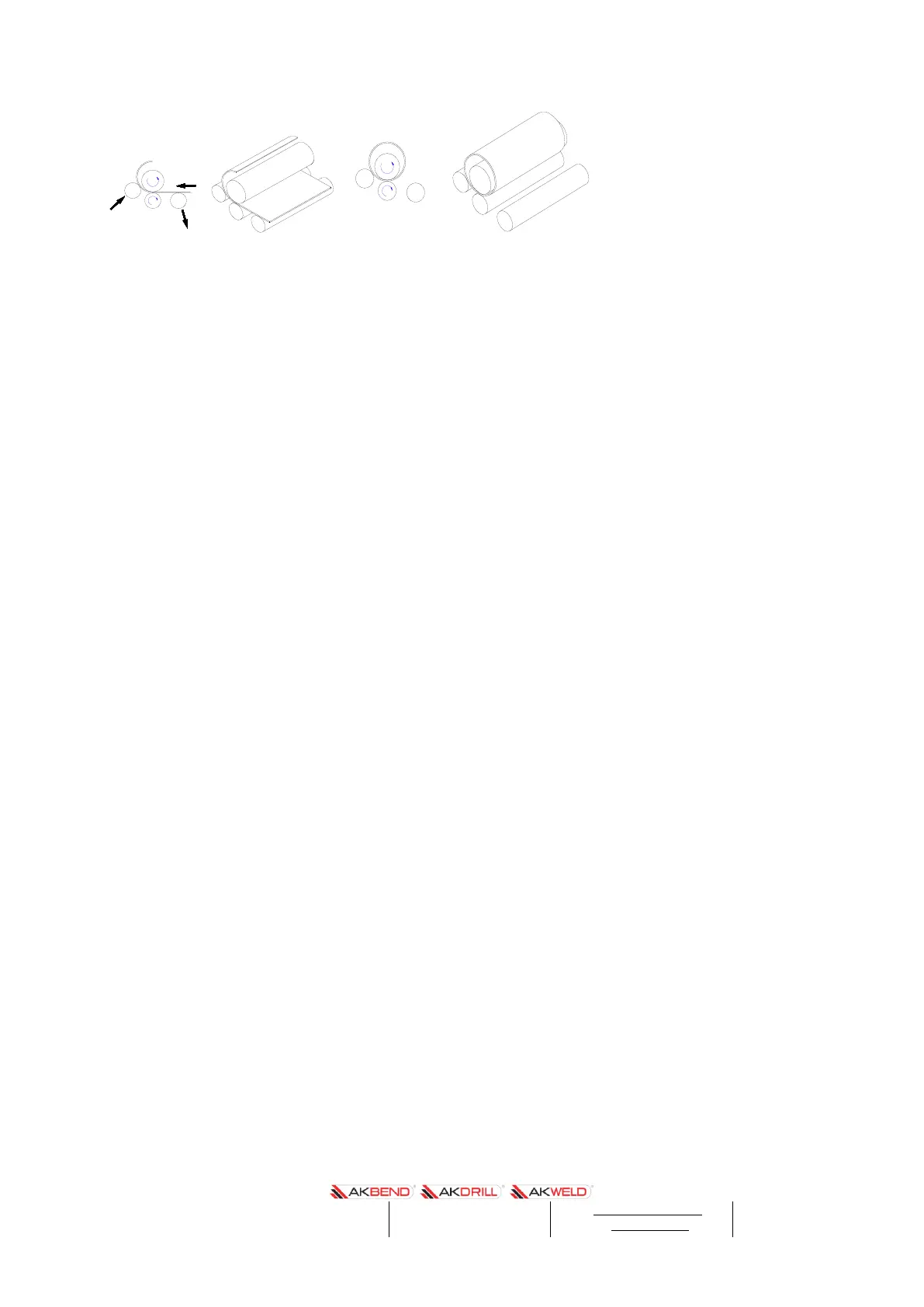

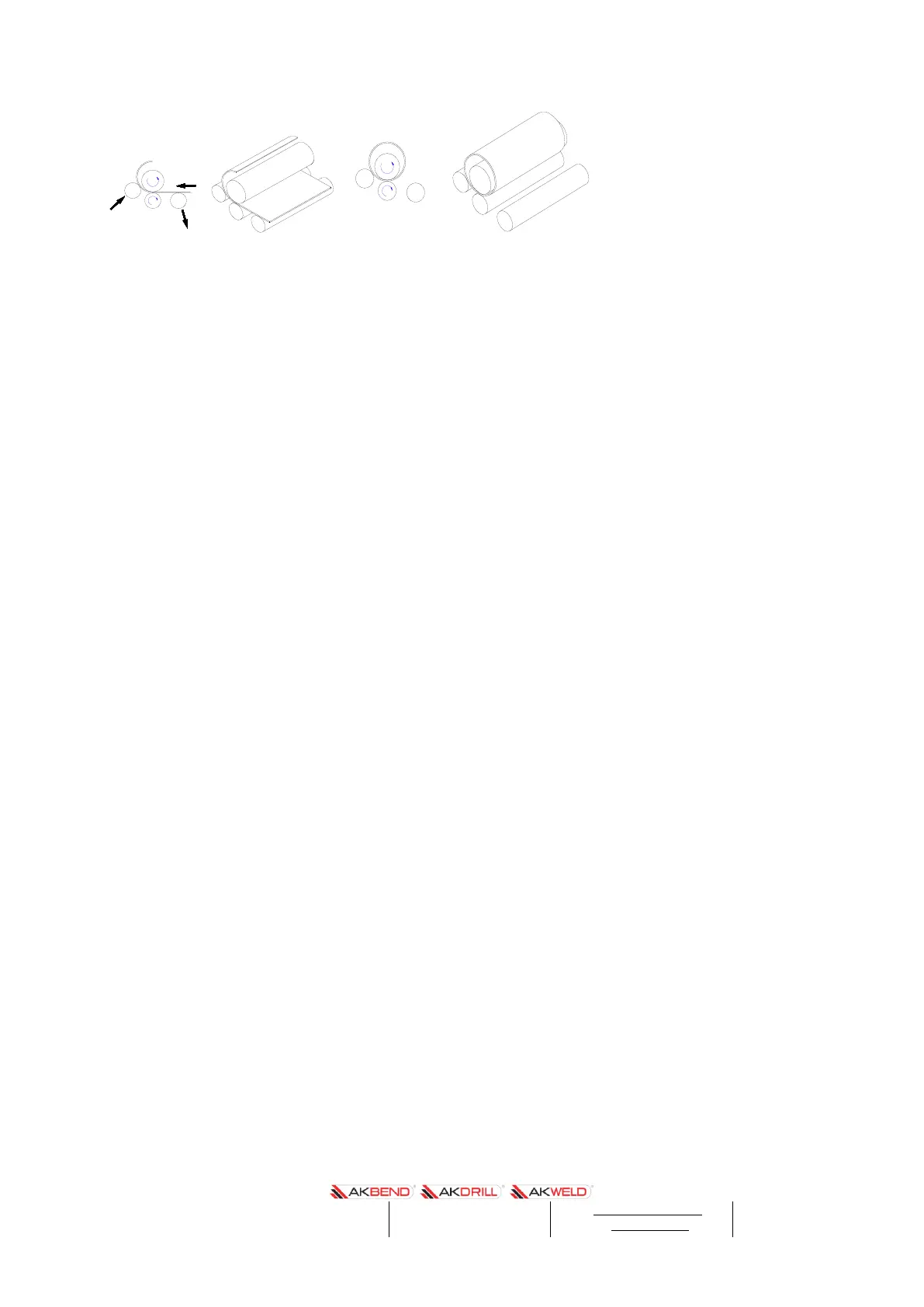

BARREL ERROR

This is the condition where the clearance on the center of the final form is greater. This is

caused by the elasticity of the rolls placed under pressure during bending process.

CAUSE 1 = the fact that plate is excessively thick for the performance of the machine

REMEDY 1 = you cannot solve this problem unless you use a machine with high performance.

CAUSE 2 = jamming of the plate because of the excessive pressure between rolls.

REMEDY 2 = slightly reduce the compression force, this may be performed at the end of the

process. As you can see clearly, the length of the first straight part shall be longer when the

compression force is lower.

BARREL

Loading...

Loading...