AKYAPAK-AHS-UserManual-2019.03.11

OVALNESS ERROR

This is the condition where the ends of the final form run into each other on one side. This

means that material diameter is not fixed and excessively wide in relation to the axes.

CAUSE = it may be caused by the dimensions of the plate to be bent

REMEDY = lower ROLL is lowered down to the lowest position and some rotation settings are

performed for the tube.

Lower ROLL is kept in the lowest position during this operation. Otherwise, welding or other

factors may cause serious damage to the machine.

BENDING ERROR

This error is caused by the fact that the force of rolls are very high. Plate comes out of the

machine and irreparably damaged.

Compression pressure of the rolls are reduced using the ROLL compression pressure setting

device.

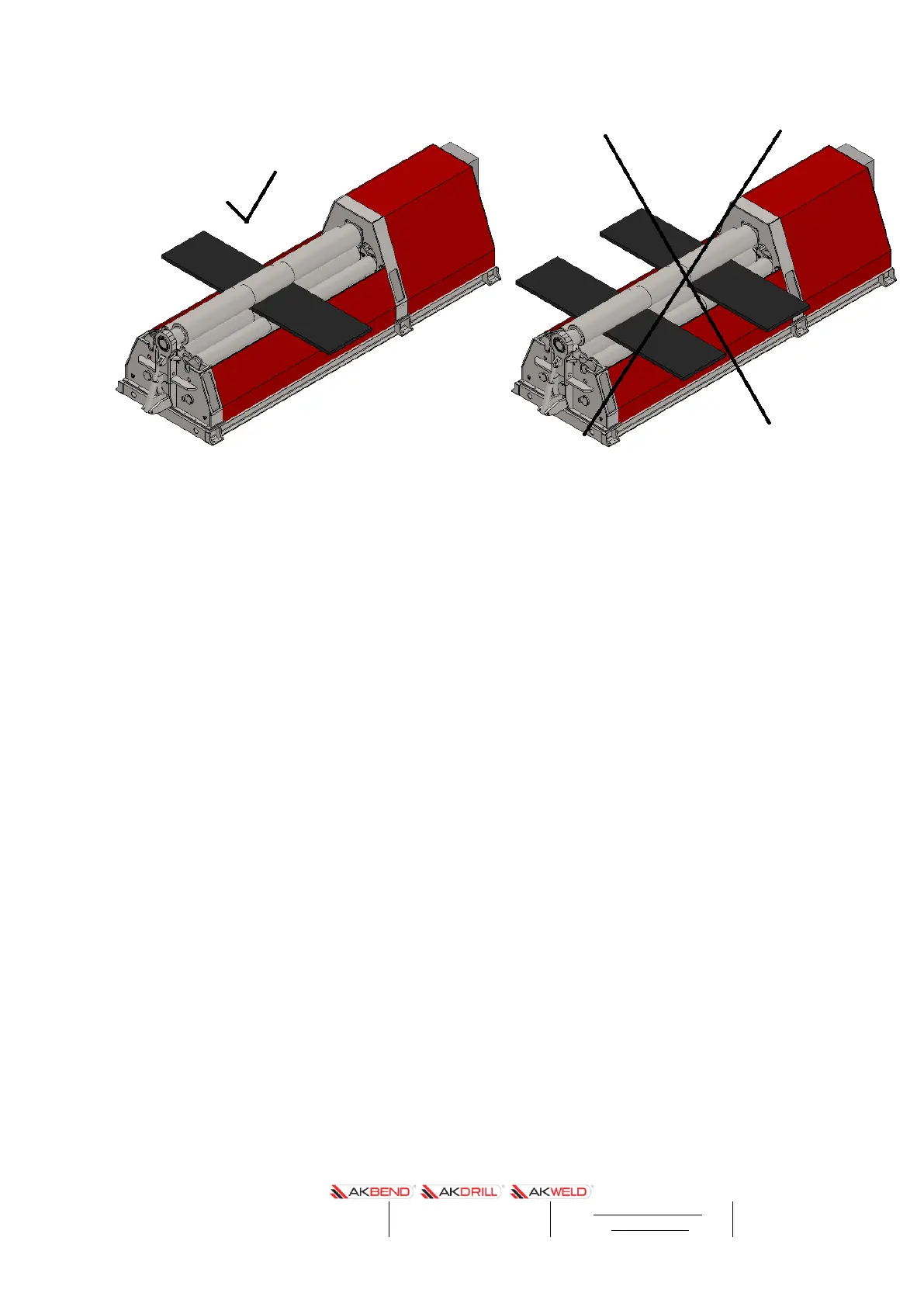

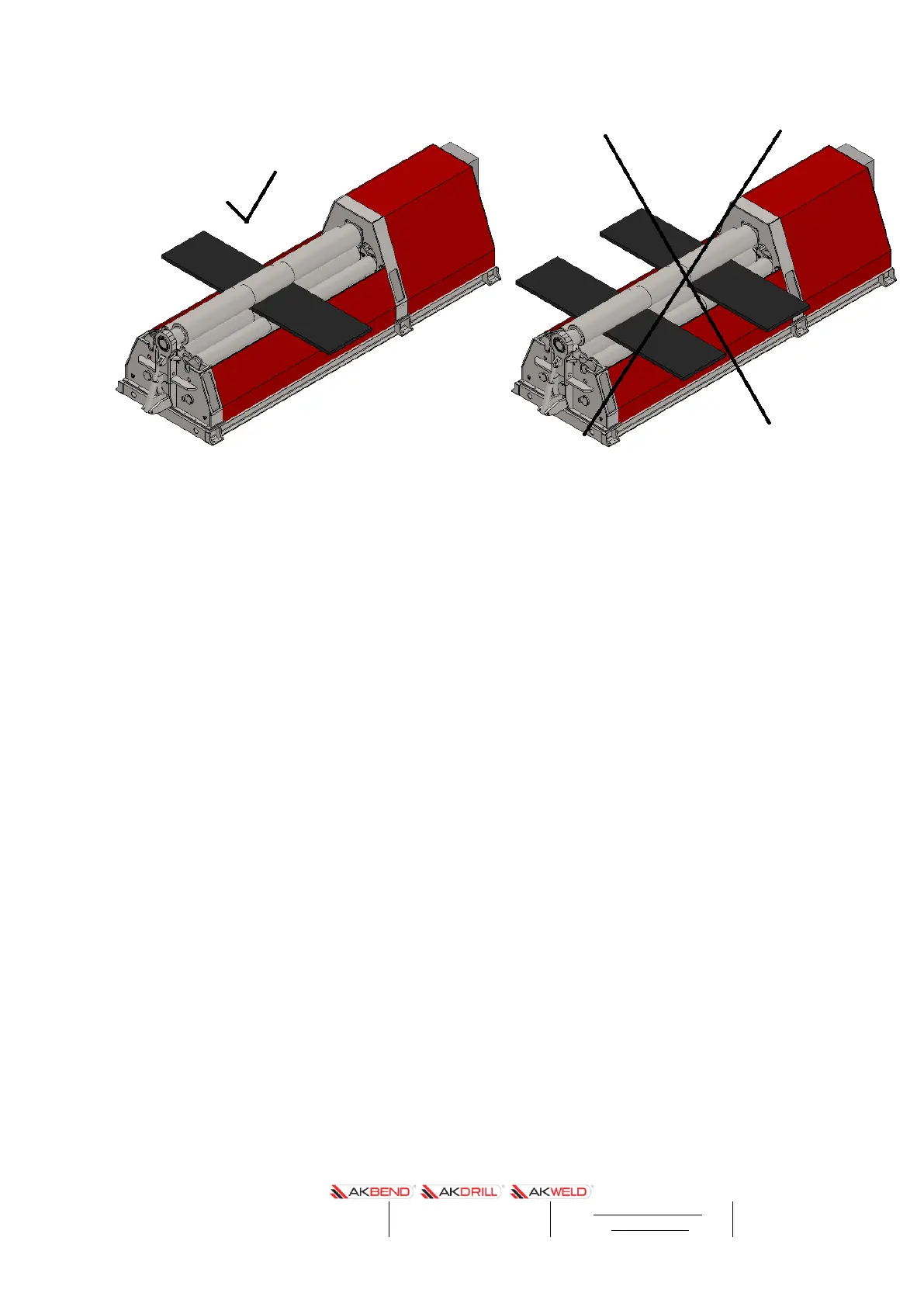

WRONG AXIS ERROR

This condition occurs when evenness of rolls is wrong and when plates with irregular

thickness are used; alignments and evenness shall be checked in this condition. There is no

solution as this is caused by the material itself.

Loading...

Loading...