Rockwell Automation Publication 1756-RM003N-EN-P - October 2011 511

Special Instructions (FBC, DDT, DTR, PID) Chapter 13

Proportional Integral

Derivative (PID)

The PID instruction controls a process variable such as flow, pressure,

temperature, or level.

Operands:

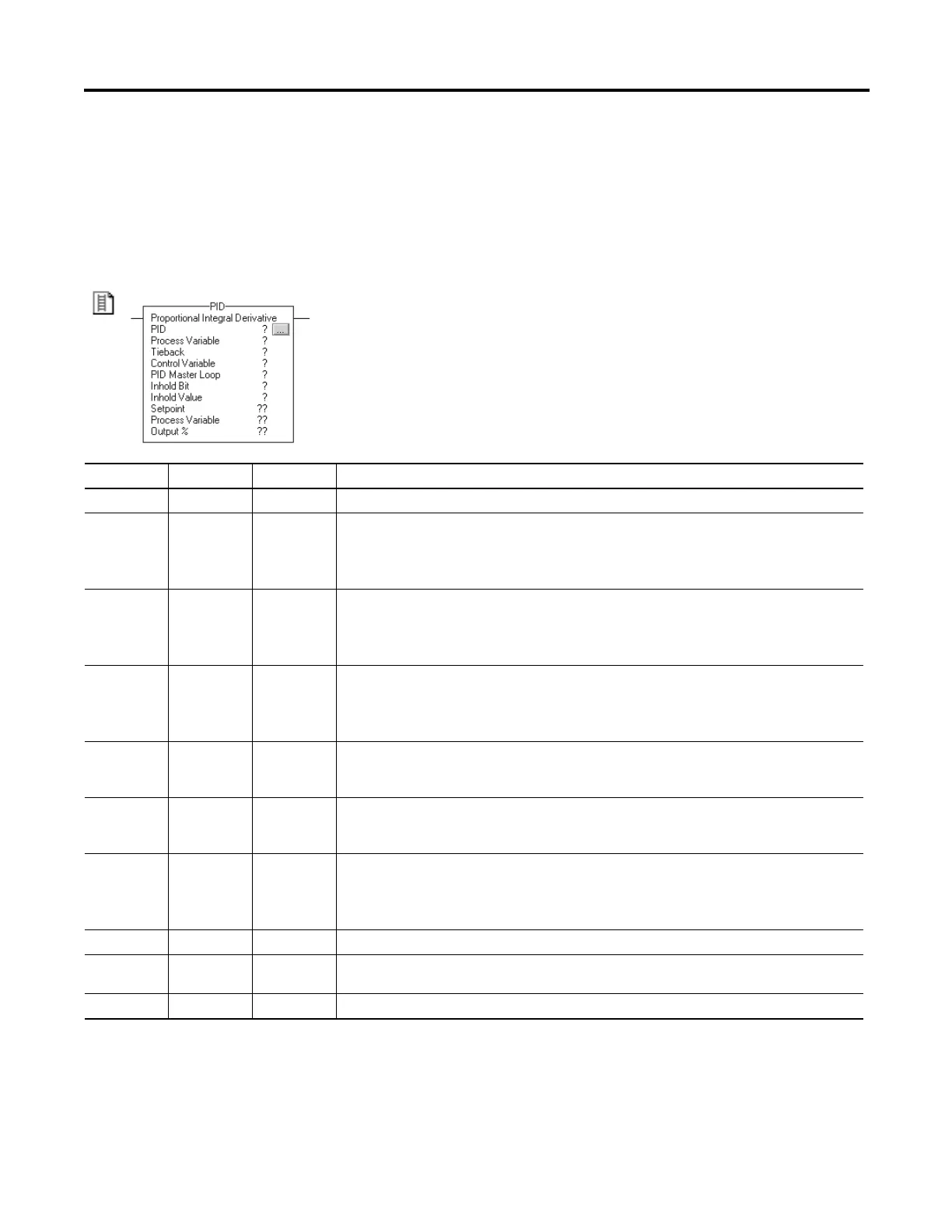

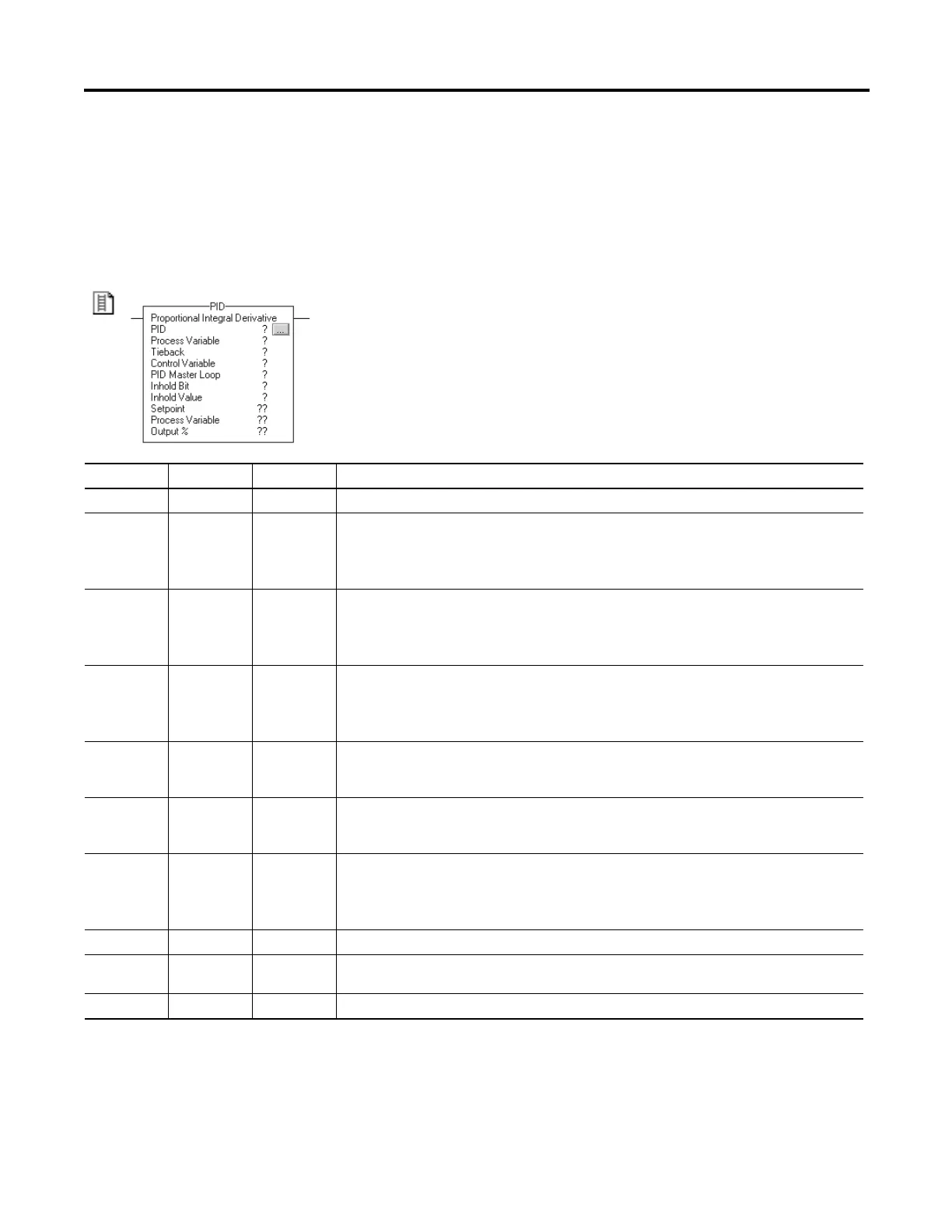

Relay Ladder

Operand Type Format Description

PID PID Structure PID structure

Process

variable

SINT

INT

DINT

REAL

Tag Value you want to control

Tieback SINT

INT

DINT

REAL

Immediate

Tag

(Optional) Output of a hardware hand/auto station that is bypassing the output of the controller

Enter 0 if you don’t want to use this parameter.

Control

variable

SINT

INT

DINT

REAL

Tag Value that goes to the final control device (valve, damper, and so forth)

If you are using the deadband, the Control variable must be REAL or it will be forced to 0 when the

error is within the deadband.

PID master

loop

PID Structure (Optional) PID tag for the master PID

If you are performing cascade control and this PID is a slave loop, enter the name of the master PID.

Enter 0 if you don’t want to use this parameter.

Inhold bit BOOL Tag (Optional) Current status of the inhold bit from a 1756 analog output channel to support bumpless

restart

Enter 0 if you don’t want to use this parameter.

Inhold value SINT

INT

DINT

REAL

Tag (Optional) Data readback value from a 1756 analog output channel to support bumpless restart

Enter 0 if you don’t want to use this parameter.

Setpoint Displays current value of the setpoint

Process

variable

Displays current value of the scaled Process Variable

Output % Displays current output percentage value

Loading...

Loading...