526 Rockwell Automation Publication 1756-RM003N-EN-P - October 2011

Chapter 13 Special Instructions (FBC, DDT, DTR, PID)

Instructions for setting a bumpless restart.

Derivative Smoothing

The derivative calculation is enhanced by a derivative smoothing filter. This

first order, low pass, digital filter helps to minimize large derivative term spikes

caused by noise in the PV. This smoothing becomes more aggressive with

larger values of derivative gain. You can disable derivative smoothing if your

process requires very large values of derivative gain (K

d

> 10, for example). To

disable derivative smoothing, select the “No derivative smoothing” option on

the Configuration tab or set the .NDF bit in the PID structure.

Set the Deadband

The adjustable deadband lets you select an error range above and below the

setpoint where output does not change as long as the error remains within this

range. This deadband lets you control how closely the process variable matches

the setpoint without changing the output. The deadband also helps to

minimize wear and tear on your final control device.

Do this Details

Configure the 1756 analog output module’s channel that

receives the control variable from the PID instruction

Select the “hold for initialization” checkbox on the properties page for the specific channel of

the module.

This tells the analog output module that when the controller returns to Run mode or re-

establishes communications with the module, the module should hold the analog output at its

current value until the value sent from the controller matches (within 0.1% of span) the

current value used by the output channel. The controller’s output will ramp to the currently

held output value by making use of the .BIAS term. This ramping is similar to auto

bumpless transfer.

Enter the Inhold bit tag and Inhold Value tag in the

PID instruction

The 1756 analog output module returns two values for each channel in its input data

structure. The InHold status bit (.Ch2InHold, for example), when true, indicates that the

analog output channel is holding its value. The Data readback value (.Ch2Data, for example)

shows the current output value in engineering units.

Enter the tag of the InHold status bit as the InHold bit parameter of the PID instruction. Enter

the tag of the Data readback value as the Inhold Value parameter.

When he Inhold bit goes true, the PID instruction moves the Inhold Value into the Control

variable output and re-initializes to support a bumpless restart at that value. When the analog

output module receives this value back from the controller, it turns off the InHold status bit,

which allows the PID instruction to start controlling normally.

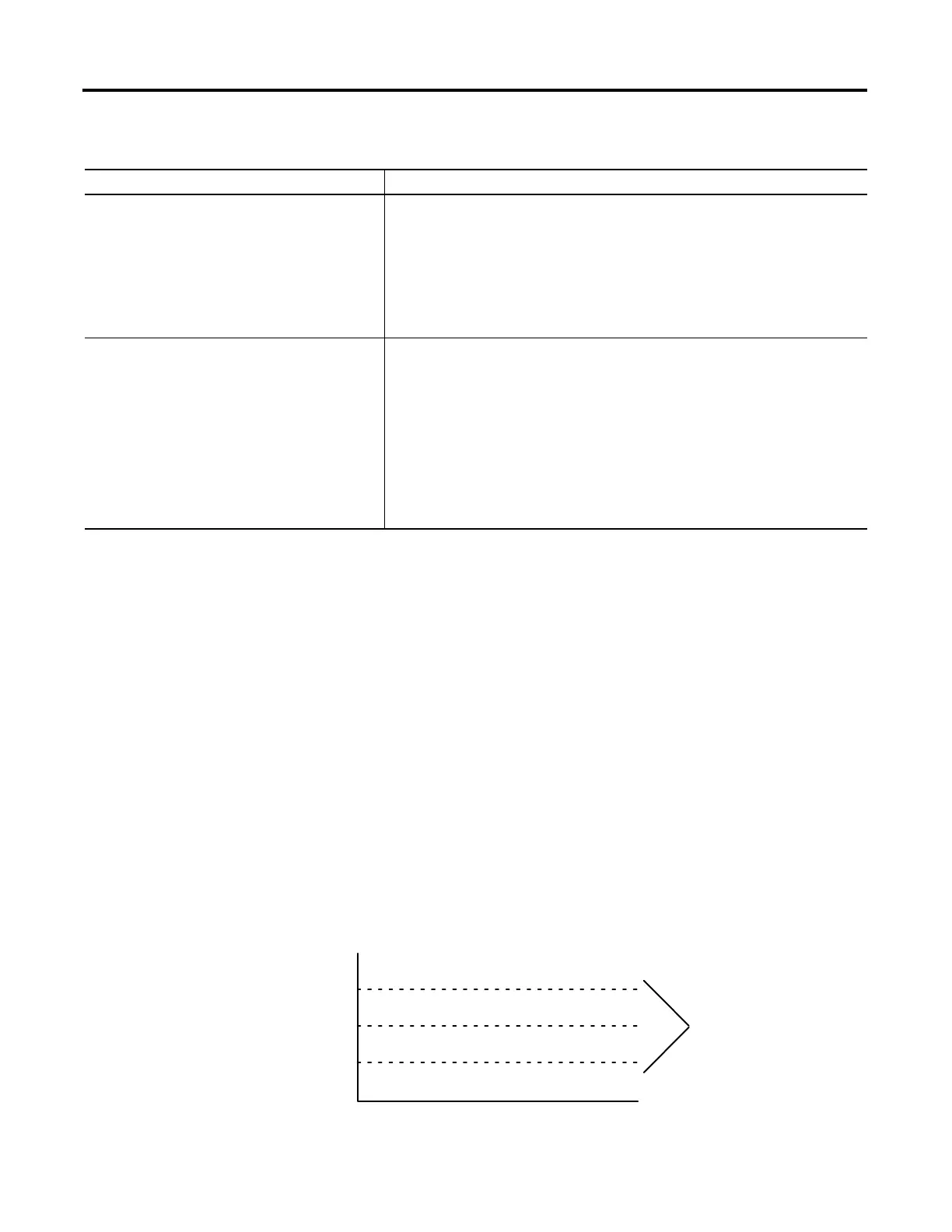

Error Within Deadband Range

+ Deadband

Setpoint

- Deadband

Time

41026

Loading...

Loading...