Rockwell Automation Publication 1756-RM003N-EN-P - October 2011 667

Function Block Attributes Appendix B

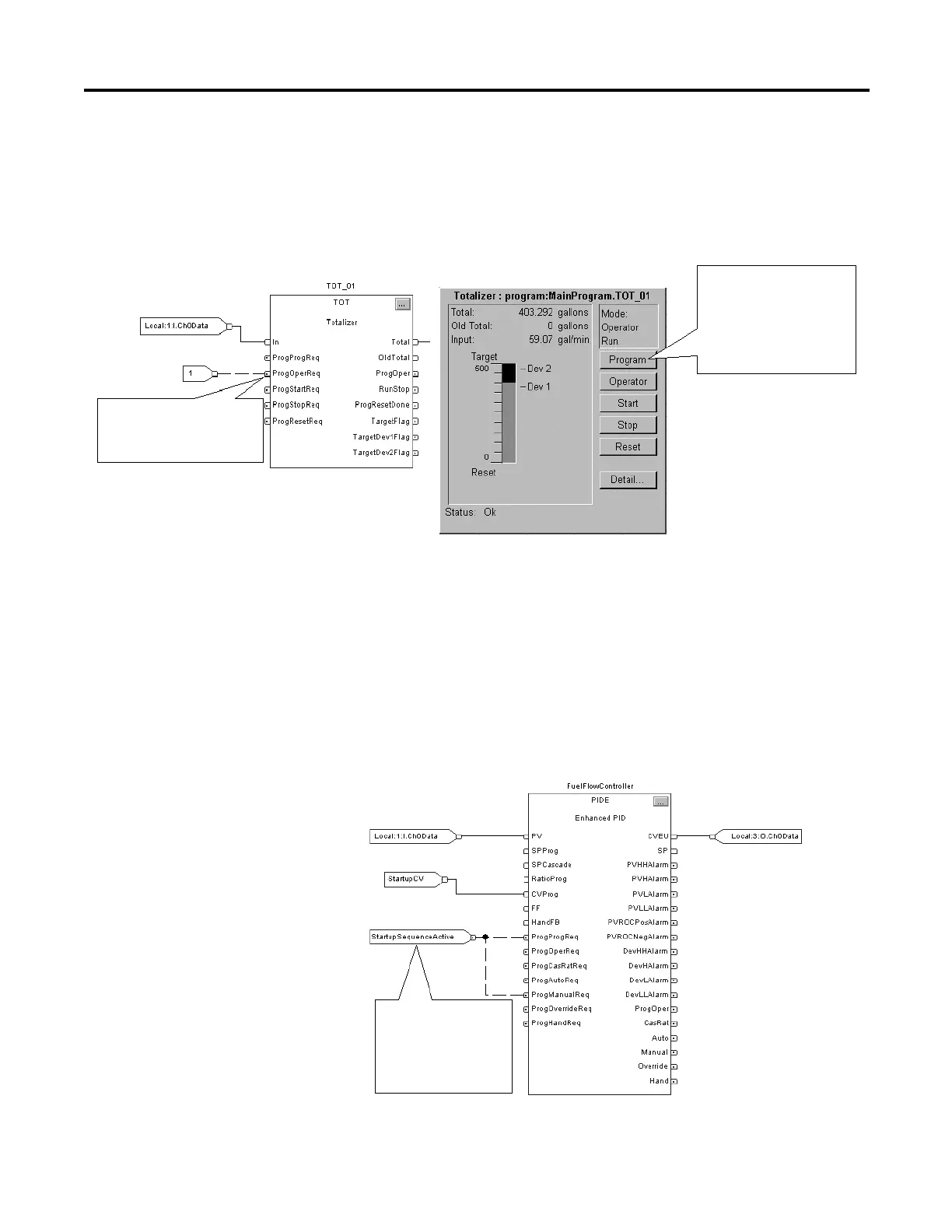

For example, let’s assume that a Totalizer instruction will always be used in

Operator control, and your user program will never control the running or

stopping of the Totalizer. In this case, you could wire a literal value of 1 into the

ProgOperReq. This would prevent the operator from ever putting the Totalizer

into Program control by setting the OperProgReq from an operator interface

device.

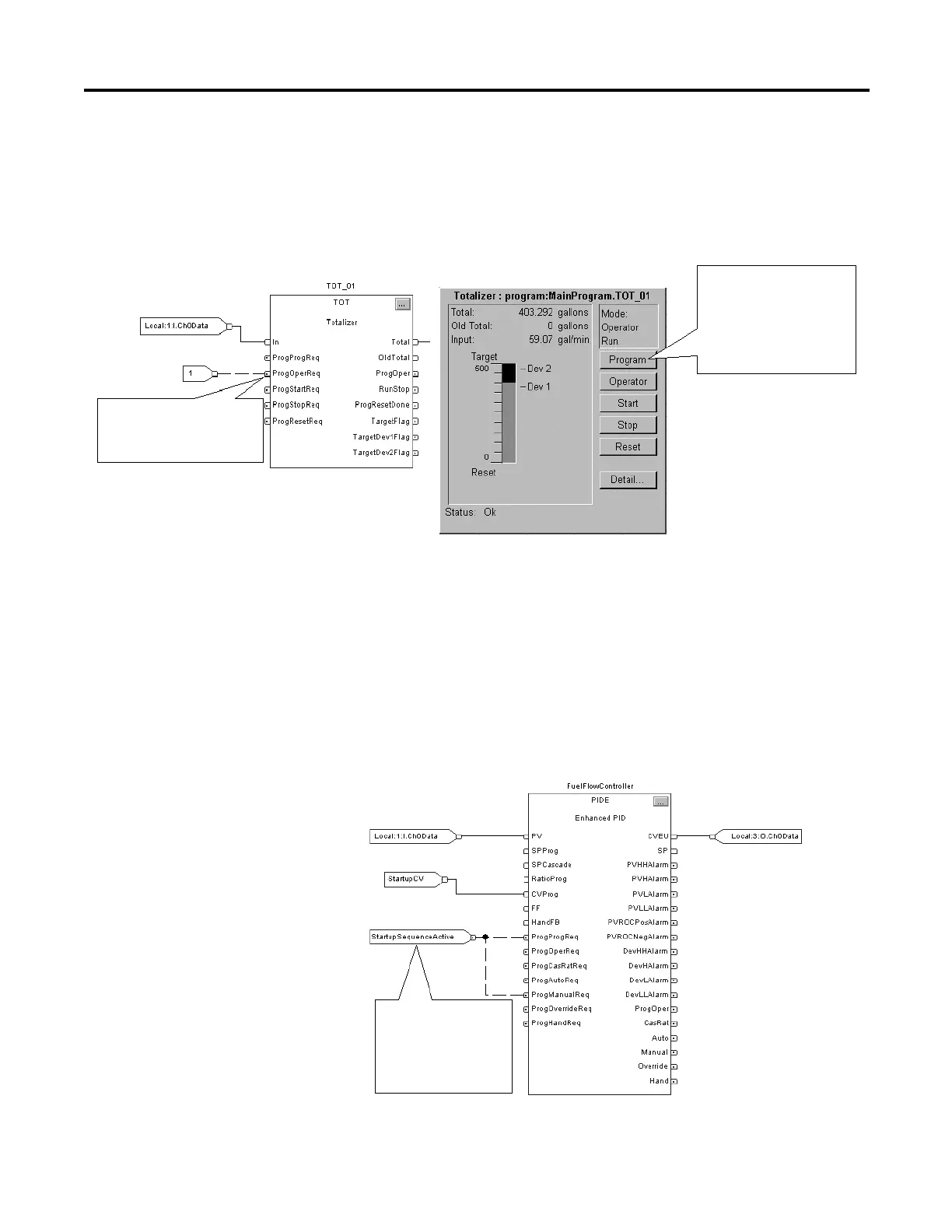

Likewise, constantly setting the ProgProgReq can ‘lock’ the instruction into

Program control. This is useful for automatic startup sequences when you want

the program to control the action of the instruction without worrying about an

operator inadvertently taking control of the instruction.

In this example, you have the program set the ProgProgReq input during the

startup, and then clear the ProgProgReq input once the startup was complete.

Once the ProgProgReq input is cleared, the instruction remains in Program

control until it receives a request to change. For example, the operator could set

the OperOperReq input from a faceplate to take over control of that instruction.

The following example shows how to lock an instruction into Program control.

Because the ProgOperReq input is

always set, pressing the “Program”

button on the faceplate (which sets

the OperProgReg input) has no effect.

Normally, setting OperProgReq puts

the TOT in Program control.

Wiring a ‘1’ into ProgOperReq means

the user program always wants the

TOT to be in Operator control

When StartupSequenceActive

is set, the PIDE instruction is

placed in Program control and

Manual mode. The StartupCV

value is used as the loop output.

Loading...

Loading...