Rockwell Automation Publication 1756-RM003N-EN-P - October 2011 73

FactoryTalk Alarms and Events Logix-based Instructions (ALMD, ALMA) Chapter 1

You can edit all aspects of the alarm configuration offline and online. Online

edits of new and existing alarms are immediately sent to FactoryTalk subscribers

(legacy HMI terminals that are just polling the tags do not automatically update).

FactoryTalk subscribers do not have to re-subscribe to receive updated

information. Online changes automatically propagate from the controller alarm

structure to the rest of the architecture.

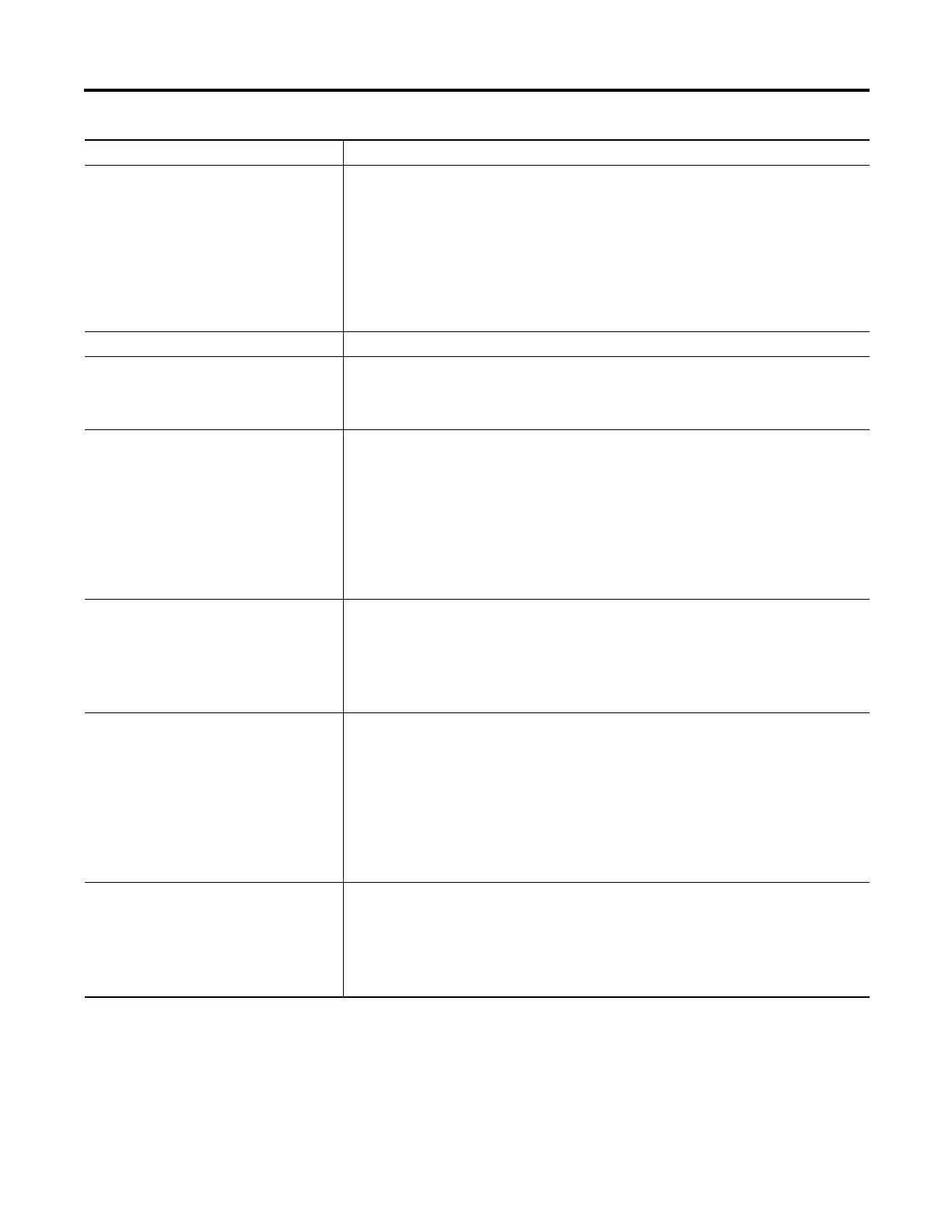

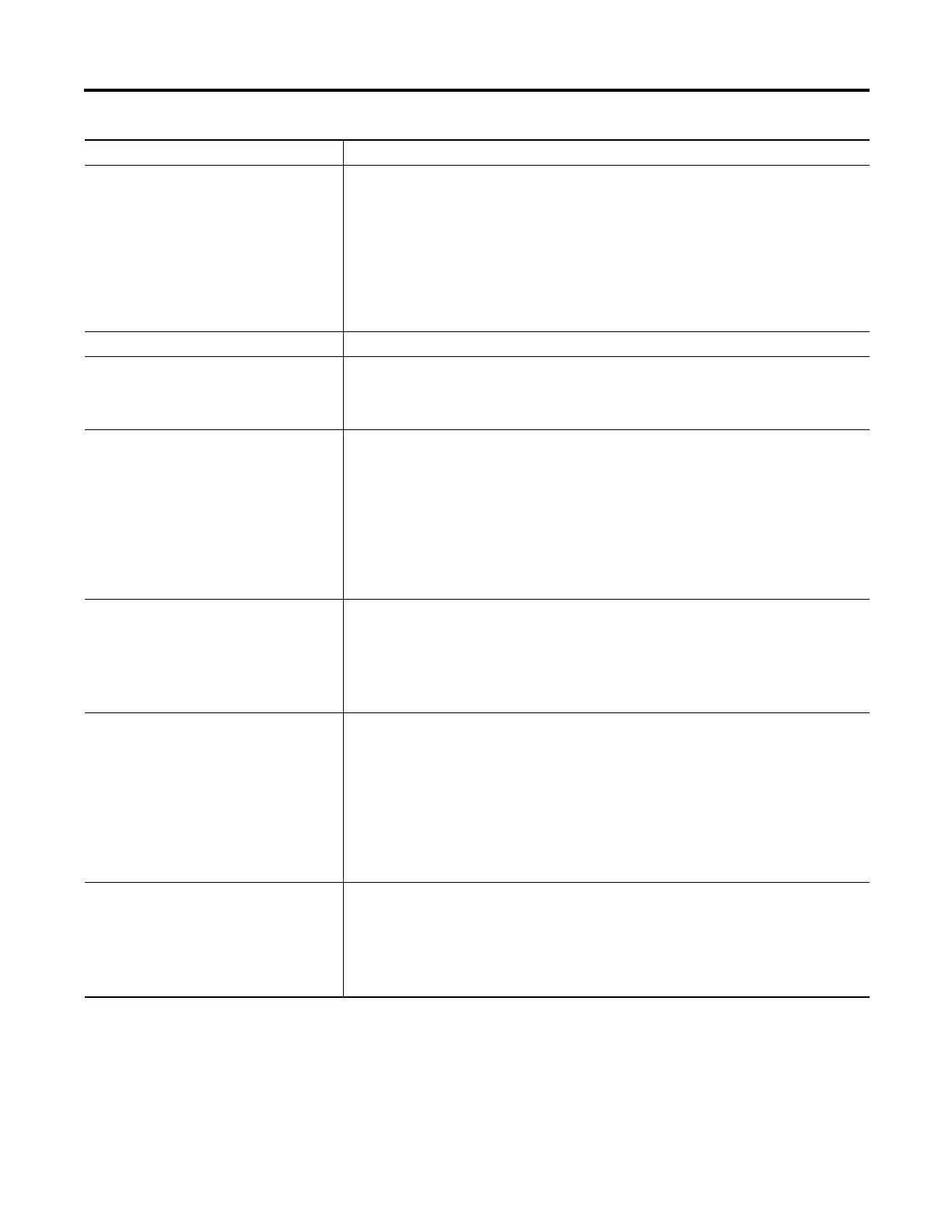

Severity Select a severity range from 1…1000 to rank the importance of an alarm condition. A severity of 1 is

for low priority alarms; a severity of 1000 is for an emergency condition.

By default, in the FactoryTalk Alarms and Events system, severity ranges are mapped to priorities as

follows:

· 1…250 are low priority.

· 251…500 are medium priority.

· 501…750 are high priority.

· 751…1000 are urgent priority.

You can configure the severity-to-priority mapping in the FactoryTalk Alarms and Events system. See

the FactoryTalk help for details.

Minimum Duration Enter the amount of time in ms an alarm condition must be active before reporting the alarm.

Latched - ALMD instruction Select Latched if you want the alarm to stay active (InAlarm) after the alarm condition returns to

inactive (normal). Latched alarms require a reset command to transition to normal. The reset command

must be received after the condition returns to normal.

Acknowledge commands will not reset a latched alarm.

Deadband - ALMA instruction Specify a Deadband value to reduce alarm condition chattering caused by small fluctuations in the In

value.

The deadband value does not affect the alarm limit for the transition into the active state, and is also

not used during the Minimum Duration interval.

Once a level condition becomes active (InAlarm), it will remain active until the In value crosses back

over the limit by the specified deadband. For example, if the High limit is 80, the Low limit is 20, and

the Deadband is 5, the High condition will be active at ≥ 80 and return to normal at ≤ 75; the Low

condition will be active at ≤ 20 and return to normal

at ≥ ≤ 25.

The Deadband has no effect on Rate of Change alarm conditions.

Acknowledgement Required Alarms are configured to require acknowledgement by default. Acknowledgement indicates that an

operator is aware of the alarm condition, whether or not conditions have returned to normal.

Clear the Acknowledgement Required setting when you want the alarm to appear and disappear from

the Alarm Summary on the HMI with no operator interaction.

Alarms that do not require acknowledgement always have the Acked status set.

If a digital alarm is configured as latched, the reset command also acknowledges the alarm.

Alarm class Use the alarm class to group related alarms. Specify the alarm class exactly the same for each alarm

you want in the same class. The alarm class is case sensitive.

For example, specify class Tank Farm A to group all the tank alarms for a specific area. Or specify class

Control Loop to group all alarms for PID loops.

You can then display and filter alarms at the HMI based on the class. For example, an operator can

display all tank alarms or all PID loop alarms.

The alarm class does not limit the alarms that an Alarm Summary object subscribes to. Use the alarm

class to filter the alarms that display to an operator once they have been received by the Alarm

Summary object. FactoryTalk View software can filter the alarm class substituting wild cards for

characters.

View command Execute a command on the operator station when requested by an operator for a specific alarm. This

lets an operator execute any standard FactoryTalk View command, such as call specific faceplates and

displays, execute macros, access help files, and launch external applications. When the alarm

condition occurs and is displayed to the operator, a button on the summary and banner displays lets

the operator run an associated view command.

Be careful to enter the correct command syntax and test the command at runtime as there is no error

checking performed when the command is entered.

Option Description

Loading...

Loading...