APPENDIX A: TECHNICAL SPECIFICATIONS

UB25 LINEAR DC RESISTANCE WELDING CONTROL

A-2 990-665

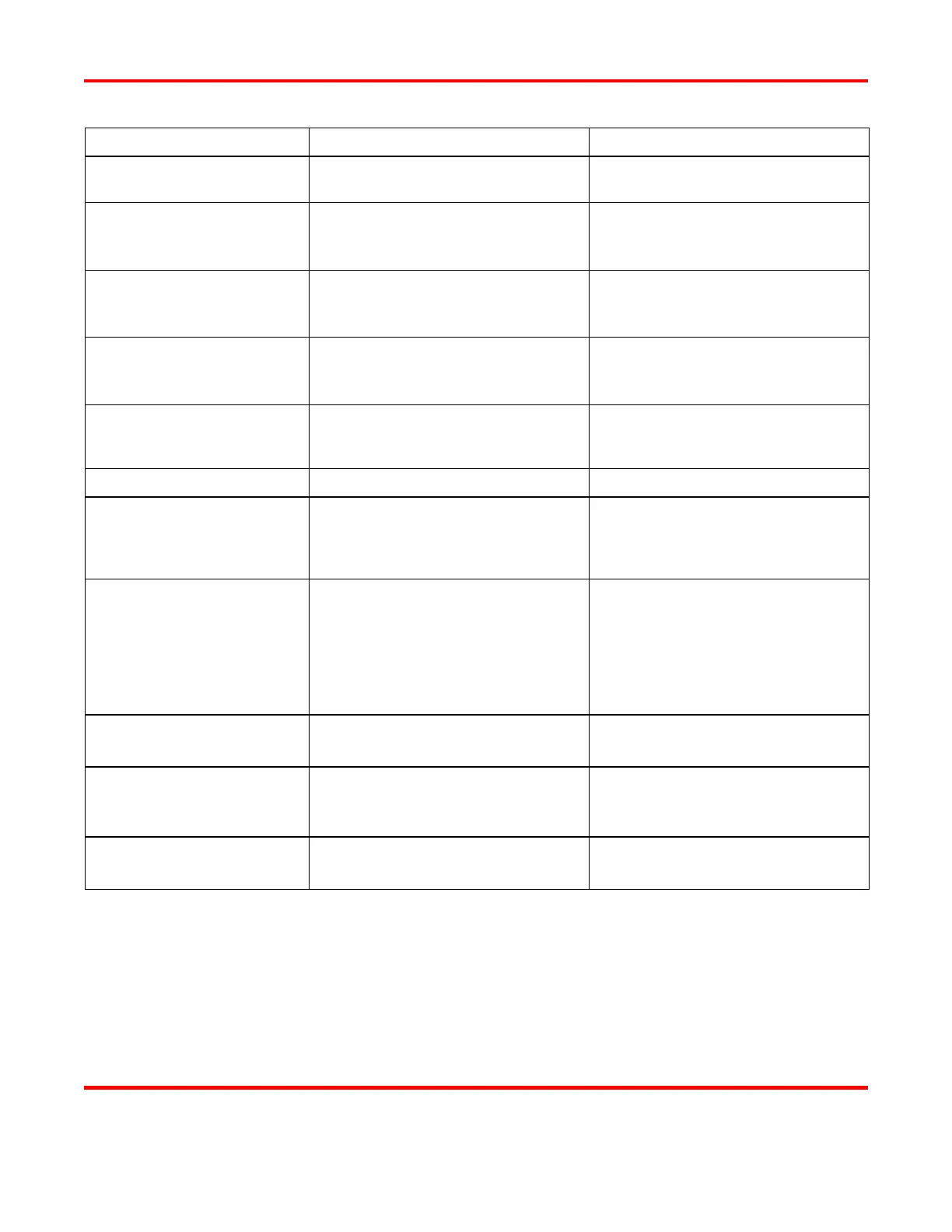

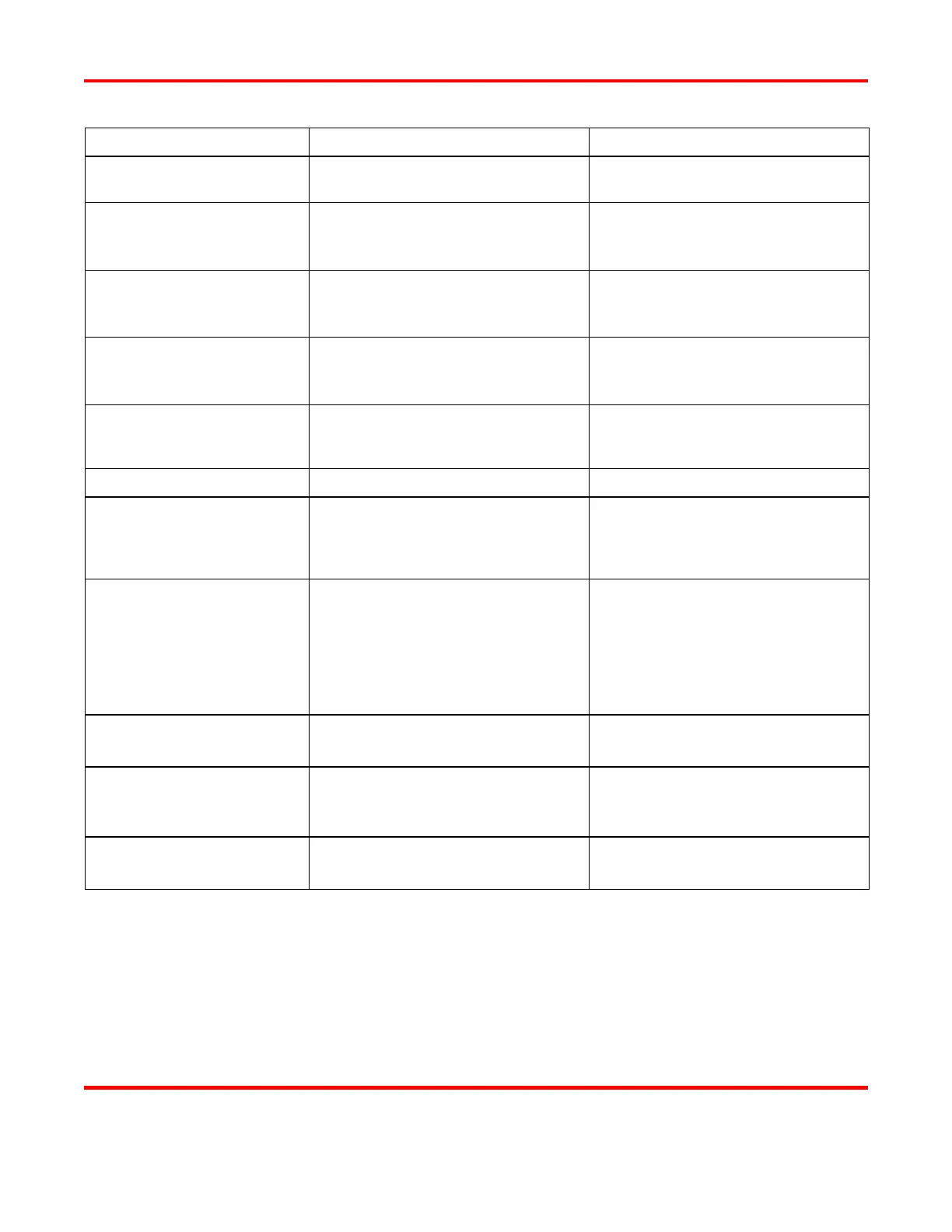

DESCRIPTION VALUE NOTES

Steady State Regulation

During Line Fluctuations

Output: +/- 2% of reading

Line voltage within + 15% / -10%

tolerance.

Regulation During Load

Resistance Fluctuation

Current:

Voltage:

Power:

± 2% of setting ± 2 A

± 2% of setting ± 0.05 V

± 5% of setting ± 20 W

Load variation from 0.5 to 10 milliohms,

exclusive of ripple. After weld time of 2

ms.

Steady State Control

Accuracy

Current:

Voltage:

Power:

± 2% of setting ± 2 A

± 2% of setting ± 0.05 V

± 5% of setting ± 20 W

After weld time of 2ms.

Initial Control Accuracy

(Maximum transients)

Current:

Voltage:

Power:

± 5% of setting ± 2 A

± 5% of setting ± 0.05 V

± 10% of setting ± 20 W

During first 2 ms with load resistance

greater than 2 milliohms.

Current, Voltage, Power

Repeatability:

All modes: ± 2%

Weld to weld repeatability with fixed

load resistance and input line voltage,

steady state.

Rise Time:

Limited by external secondary circuit

Data Communications

Remote capability to upload / download

weld schedule; monitor welds; set up

parameters; select schedule; and read

weld results buffer

Weld Monitor:

Range:

Current from 0 to 1.2 kiloamps

Voltage from 0 to 6.5 volts

Power from 0 to 8.0 kilowatts

User selectable limits on peak values of

one of three parameters: current, voltage,

or power. When a parameter goes outside

of limits, the unit can be set to report the

error, terminate the weld, or inhibit a

second pulse. APC functionality also

included.

Current Monitoring

Accuracy

The sum of ± 2% of setting and ± 2 A

Reference is actual current delivered.

Average value after settling time.

Voltage Monitoring Accuracy

The sum of ± 2% of setting and ± 0.05 V

at values greater than 0.1 V

Reference is actual voltage delivered.

Average value after settling time.

Voltage monitoring is not guaranteed

below 0.1 V.

Power Monitoring Accuracy

The sum of ± 5% of setting and ± 20 W

Reference is actual power delivered

Average value after settling time.

Loading...

Loading...