CHAPTER 5: SETUP SOFTWARE

UB25 LINEAR DC RESISTANCE WELDING CONTROL

5-8 990-665

Weld Fire Lockout Charge % Setting

1 From the WAVEFORM CHECK menu,

press the 5 key to access the WELD

FIRE LOCKOUT screen.

2 Use the numeric keypad to enter the

required amount of energy in the

capacitor bank before the next weld is

allowed.

3 Press MENU

WAVEFORM CHECK menu. The

WELD FIRE LOCKOUT CHRG%

line will display your programmed

setting along with the actual %

CHARGE from the most recent weld.

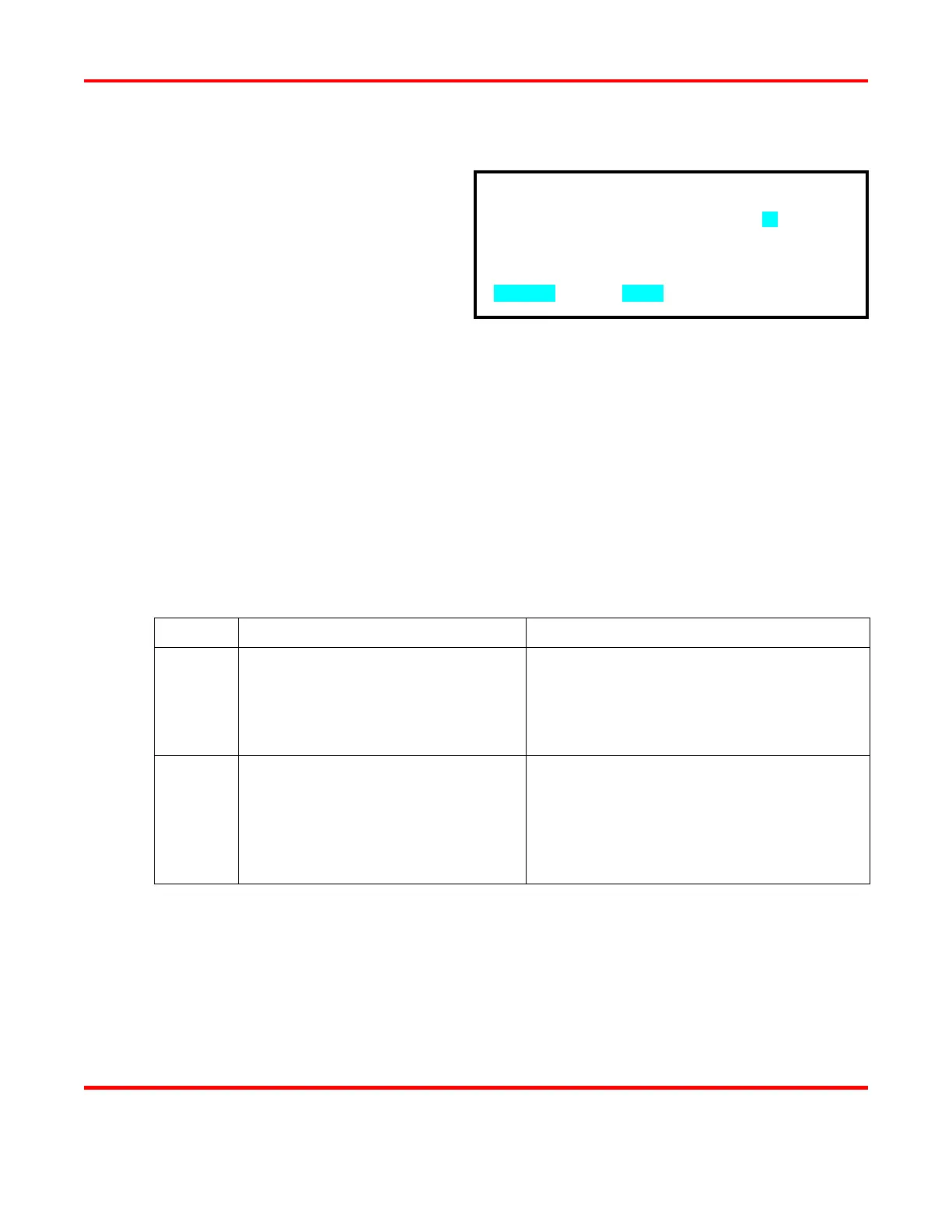

Footswitch Weld Abort

1 Go to the SETUP 1 screen.

2 Press the 1 key to toggle between FOOTSWITCH WELD ABORT ON and FOOTSWITCH

WELD ABORT OFF.

STATE PREFERRED APPLICATION FUNCTION

ON

Human operated welding stations

where the operator holds parts.

Allows you to abort the weld process by

releasing the foot switch used with an air-

actuated weld head. Will also terminate the

welding sequence if the footswitch is opened

before the firing switch is initiated.

OFF

Computer or PLC controlled

welding stations. Also, for human

operated stations where tooling holds

the parts, and where the welding

sequence can be initiated with a single

momentary start pulse.

Once the footswitch (second level of a two

level footswitch) and firing switches have both

been closed

, the welding sequence will

continue to its conclusion regardless of

footswitch or firing switch position.

3 Keep pressing the MENU key on the front panel to return to the MAIN MENU.

WELD FIRE LOCKOUT CHRG%: 90

NUMBER Change, MENU Previous menu

Loading...

Loading...