Chapter One

1 - 8

Introducing Froment Load Banks

1 - 9

Non-unity Power Factor Testing

It is unusual for a generator to be presented with a purely resistive load. In real-world

applications it is much more likely that the load is made up of a combination of resistive,

inductive and capacitive elements (electric motors, lamp ballasts, etc.) which may be

continuously changing as various items of equipment are switched on and o.

The inductive and capacitive (reactive) parts of the load tend to store and then return

energy, and some proportion of the power supplied to the circuit is returned to the

generator. Consequently, more current has to flow to provide the required amount of

power to the circuit and the circuit is said to have a low (or non-unity) power factor. For

instance, to get 1kW of real power, a load with a power factor of 0.8 will require 1.25 kVA

apparent power to be supplied.

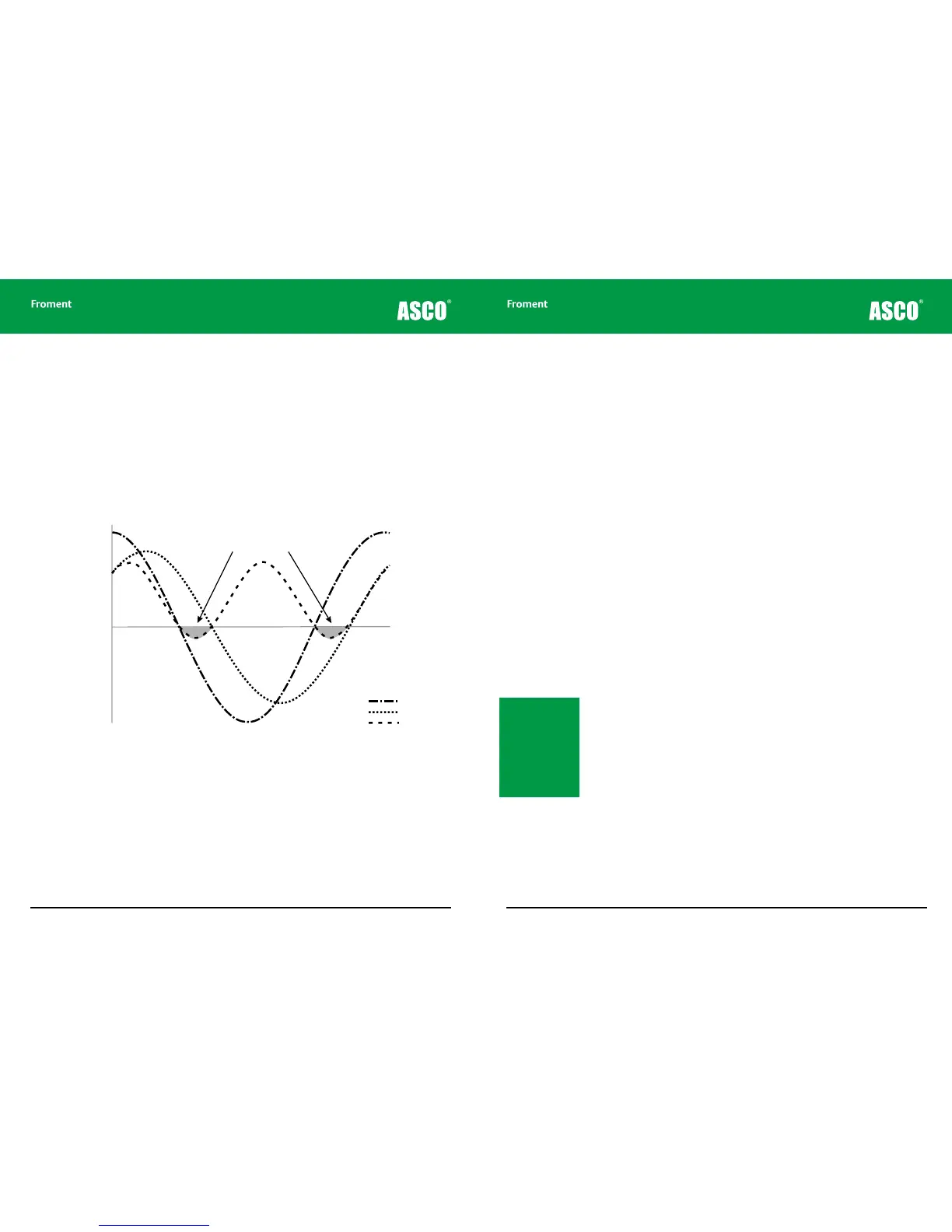

Figure 1-7 Typical power curve for power factor of 0.8

A low power factor puts additional stresses on alternators, voltage regulators, and switch

gear without necessarily putting additional load on the engine. Many generating sets are

designed to reach their maximum output when connected to a non-unity power factor

load.

To provide a realistic test, it is necessary for the load bank to simulate this situation. To

achieve this, the load bank elements need to consist of a mixture of resistive heating

elements and inductors. In some applications, capacitors are also used.

Voltage

Current

Power

0

Proportion of power

returned to the source

When is non unity power factor testing required?

This depends on the type of test that is required.

Sometimes, for smaller generators where a standardised alternator design is in use, the

electrical performance of the alternator and control gear can be assumed to be adequate.

In this case the only requirement during testing is to prove that the motive source of

the generating set is capable of operating at full power without overheating and a purely

resistive load is all that is required. This is sometimes referred to as active load (power

factor 1.0) or unity power factor.

However, in many situations the electrical performance of a generating set is of critical

importance. In these cases it is necessary to put the motive source, alternator and its

associated control gear all under stress during testing. To do this a combined load made

up of resistive and reactive elements is required.

Combined loads are also required to set up systems where multiple generating sets are

running in parallel or where it is necessary to simulate the start up of a large motor.

Multiple generator testing

Multiple generating sets running in parallel can present a problem for installers when it

comes to setting up load sharing and voltage regulation on a new system. A purely resistive

load will not provide the required load characteristics and a combined load is required for

initial calibration and testing.

What equipment is required?

Combined load testing can be accomplished by using a combined load bank (a load bank

consisting of a mixture of resistive and reactive load elements) or by running two or more

dierent type load banks in parallel.

The exact combination of equipment required will depend on the specific application.

Typically power factors from 1.0 to 0.7 are used but motor start simulation may require

a power factor as low as 0.4. See the appendices of this manual for more details of the

calculations involved.

Note: Froment com-

bined, inductive and

capacitive load banks

are in the 6000 SERIES

range. Froment purely

resistive load banks

are in the 3000 SERIES

range and Froment con-

tainerised units are in

the 8000 SERIES range.

Loading...

Loading...