Chapter One

1 - 10

Introducing Froment Load Banks

1 - 11

Movable Load Banks

Many Froment load banks are supplied for applications where they will be permanently

installed at a particular site location. However, in some applications the load bank is as a

temporary measure that is only required whilst generator tests are carried out.

This is quite common, for instance, with a new generator installation where the load bank

is used during commissioning and acceptance testing.

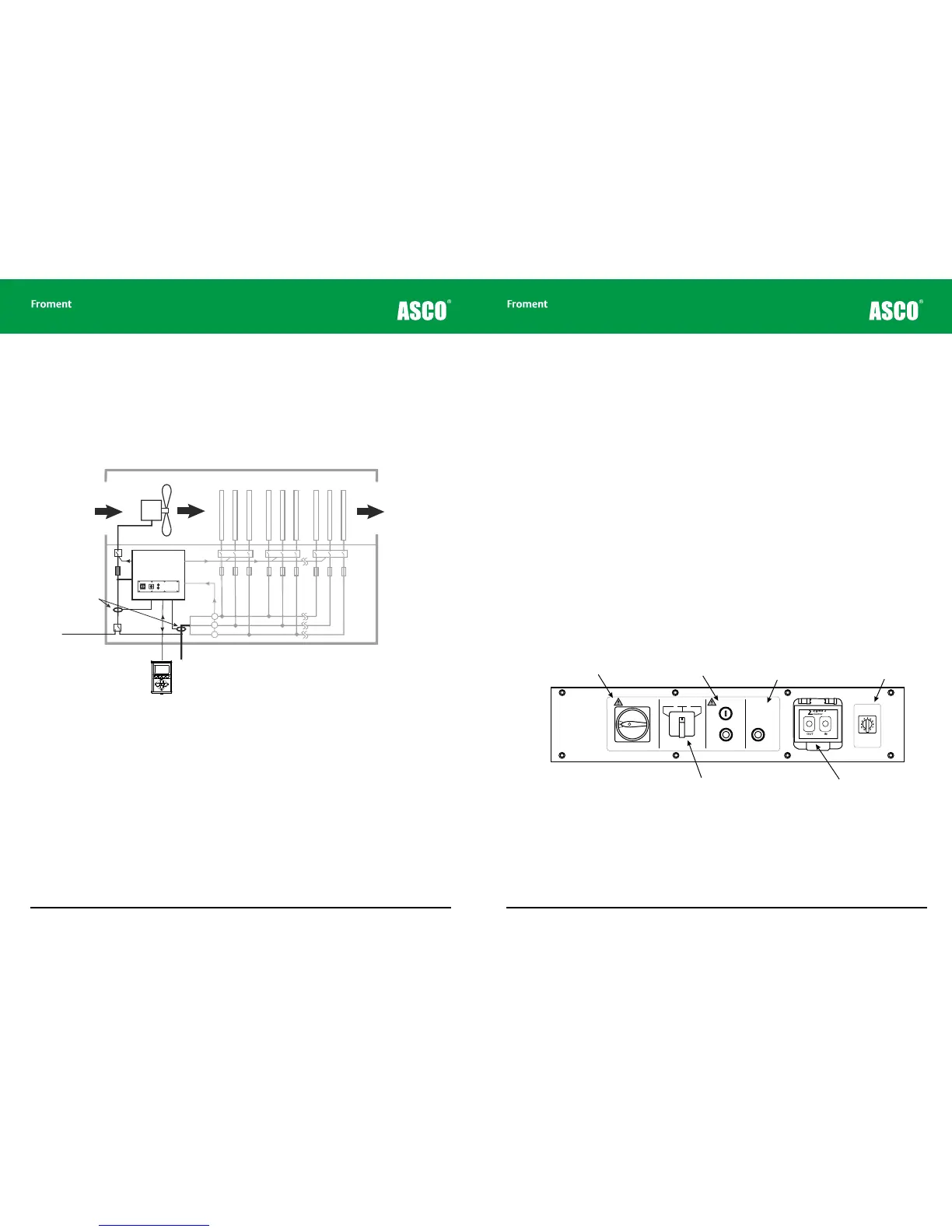

Figure 1-8 Additional components required for a movable load bank

Because of the temporary nature of the installation there are some specific design

dierences between a load bank intended for permanent installation and one intended to

be “movable”.

These include:

External power supply inlet. The load bank’s fans and control electronics can be powered

by the generator under test or (as recommended by Froment) a completely separate,

external power source. To make providing external power simple on a movable load bank,

a suitably rated IEC60309 connector is mounted on the unit either externally or behind a

lockable door with cable access.

Hot air

outlet

Cold air

inlet

Fan

motor

Air duct

Sigma II

Load bank

controller

Front panel controls

Load elements

Load

contactors

Fan

contactor

Current/Voltage

Transformers

Supply-on-test

External supply for

fan and controls

Remote control

Power supply selector switch. The load bank switch panel is fitted with a selector switch,

allowing easy selection between O, Internal supply (generator under test) or external

(Auxiliary) supply. The switch is not fitted where the load system is designed for a supply

that is incompatible with the fan supply, for example, on low voltage AC, DC, or 400Hz load

banks.

Phase rotation sensor and reversing contactors. These ensure that the fans on load

banks with three phase fans automatically rotate in the correct direction, irrespective of

how the phases are connected.

Control cable socket. The switchplate is fitted with a socket which allows Sigma 2 control

cables to be quickly attached and removed.

Multiple power cable entry options. Froment load banks designed for permanent

installations are provided with a non-ferrous gland plate that allows a fully compliant IP54

installation. The movable load banks are provided with a choice of cable entry options:

• Through a pre-punched, non-metallic plate fitted with protecting shutters or grommets.

• Through a protected slot.

• Through a nonferrous gland plate.

• Via optional externally mounted multipole (IEC60309) or single pole plug and socket

connectors.

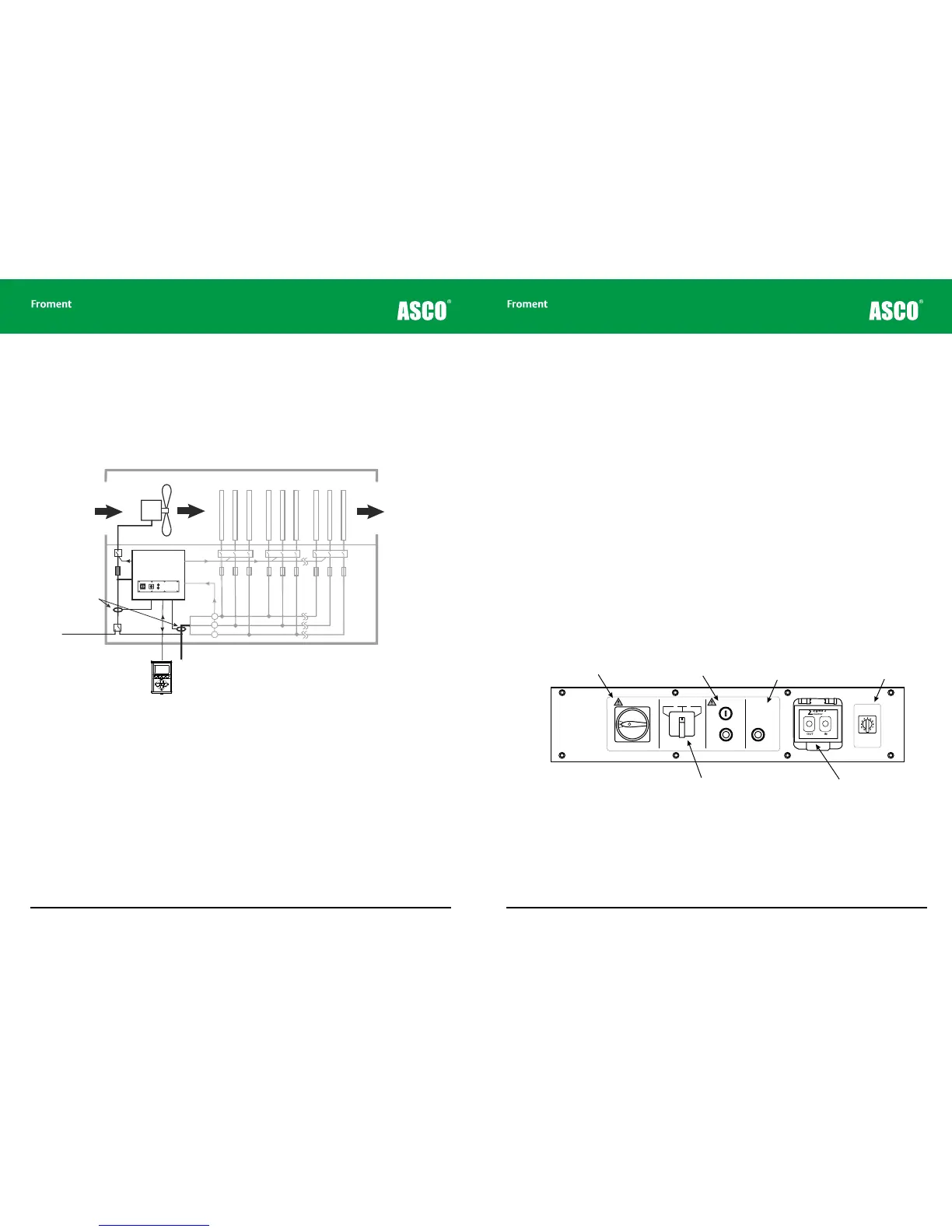

Figure 1-9 Typical movable load bank control panel.

OUT IN

Sigma 2

Control

∑

Fan and controls

supply isolator (Emergency Stop)

Fan and controls

supply source

selector

Manual stop/start

buttons

Sigma control

interface cable

sockets (in/out)

Load bank

number selector

Supply on test

status indicator

LB00060

LOAD BANK NUMBER

When controlling more

than one load bank, each

must have a different

number set on this switch.

Sigma 2

Control

∑

All doors must be shut

and guards fitted before

running this equipment.

Remove load and allow

elements to cool before

stopping the fan.

START

STOP/

RESET

Warning! Isolator for fan

and controls supply only.

Other supplies may enter this load

bank. Isolate all before working on

this equipment.

Select “Internal” only when the

Fan & Controls Supply Selector

supply-on-test equals the control circuit

rated voltage and frequency.

OFF ExternalInternal

Supply-on-Test

Status

Off: No Voltage

On: Normal

Operation

Flashing: Out of

Limits

© NJ Froment & Co. Ltd. This document may not be copied

or disclosed in whole or part without prior written authority.

Loading...

Loading...