Chapter One

1 - 4

Introducing Froment Load Banks

1 - 5

Introducing Froment Load Banks

Froment load banks are purpose designed to provide all of the facilities needed to quickly,

safely and reliably test generating equipment with outputs up to several megawatts.

Figure 1-2 Froment load bank core components

There are many variations between dierent Froment load bank models, but Figure 1-2

shows a simplified schematic of the core components to be found in most units.

The diagram contains:

• An array of load elements grouped in small steps that are individually activated by

switchgear to allow the load applied to the generator to be precisely controlled.

• A fan and duct forced air system which ensures that the heat generated during testing

is vented safely to atmosphere.

• Fuses and safety interlocks that ensure that the test can be shut down in a controlled

fashion if any problems occur.

• A microprocessor based control and three phase instrumentation system connected to

a number of highly accurate voltage and current transformers. This provides automatic

precision control of the test and allow the results to be displayed with better than 0.5%

accuracy.

Cold air

inlet

Fan

motor

Air duct

Fan

contactor

Step 1Step 1Step n

Load Elements

Hot air

outlet

Supply-on-test

Remote control

unit

External supply for

fan and controls

Sigma II

load bank

controller

Front panel controls

Load

contactors

Fuses

Phase

rotation

sensor

Current/Voltage

Transformers

Froment Load Bank Control Options

Reliable testing requires precise control of the load applied to the generator and accurate

real-time measurement of the generator’s output.

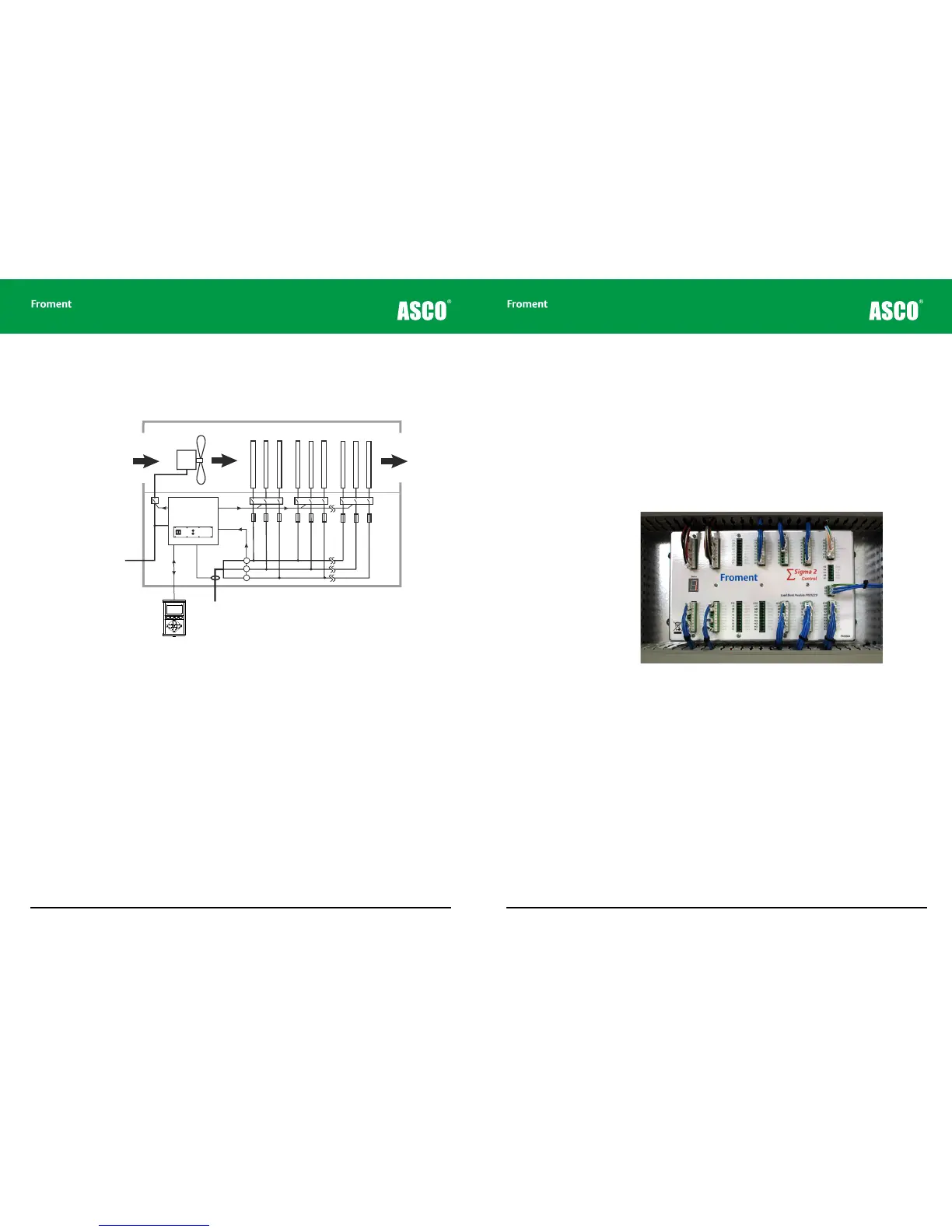

To achieve this, most Froment load banks are fitted with a Sigma 2 load control system.

Sigma 2 is a microprocessor-based control and instrumentation system specifically

developed for load bank applications.

Sigma 2 provides precise control over the operation of each load element during the test

whilst simultaneously measuring the results. The unit also provides safety monitoring and

interlocks which shut down the load bank safely should a problem occur.

Figure 1-3 Sigma 2 load bank control unit.

User control interfaces

The wide variety of dierent applications for load banks require a wide variety of user

control interfaces. These range from a very basic switch controlled system through to

sophisticated computerised control, instrumentation and data logging systems.

All Froment load banks are supplied with a built-in switch plate which contains a Fan and

Controls Supply Isolator, Start and Stop switches and (for Sigma2 controller equipped

units) Sigma control cable connectors.

The switch plate may contain other controls, depending on the specific load bank variant.

Depending on the application, the Sigma controller unit can be operated by a number of

dierent control interfaces. These include:

Loading...

Loading...