3 - 8

Operating the optional air circuit breakers (ACBs)

The circuit breaker spring motor must be fully charged before its contacts can be closed:

1. Pull on the charging handle and operate it through the full range of its stroke nine

times.

2. The lever will slacken after the ninth stroke, indicating that the spring is fully charged.

3. Lift the clear plastic safety cover and press the green I button to close the circuit

breaker contacts.

4. Lift the clear plastic safety cover and press the red O button to open the circuit breaker

contacts.

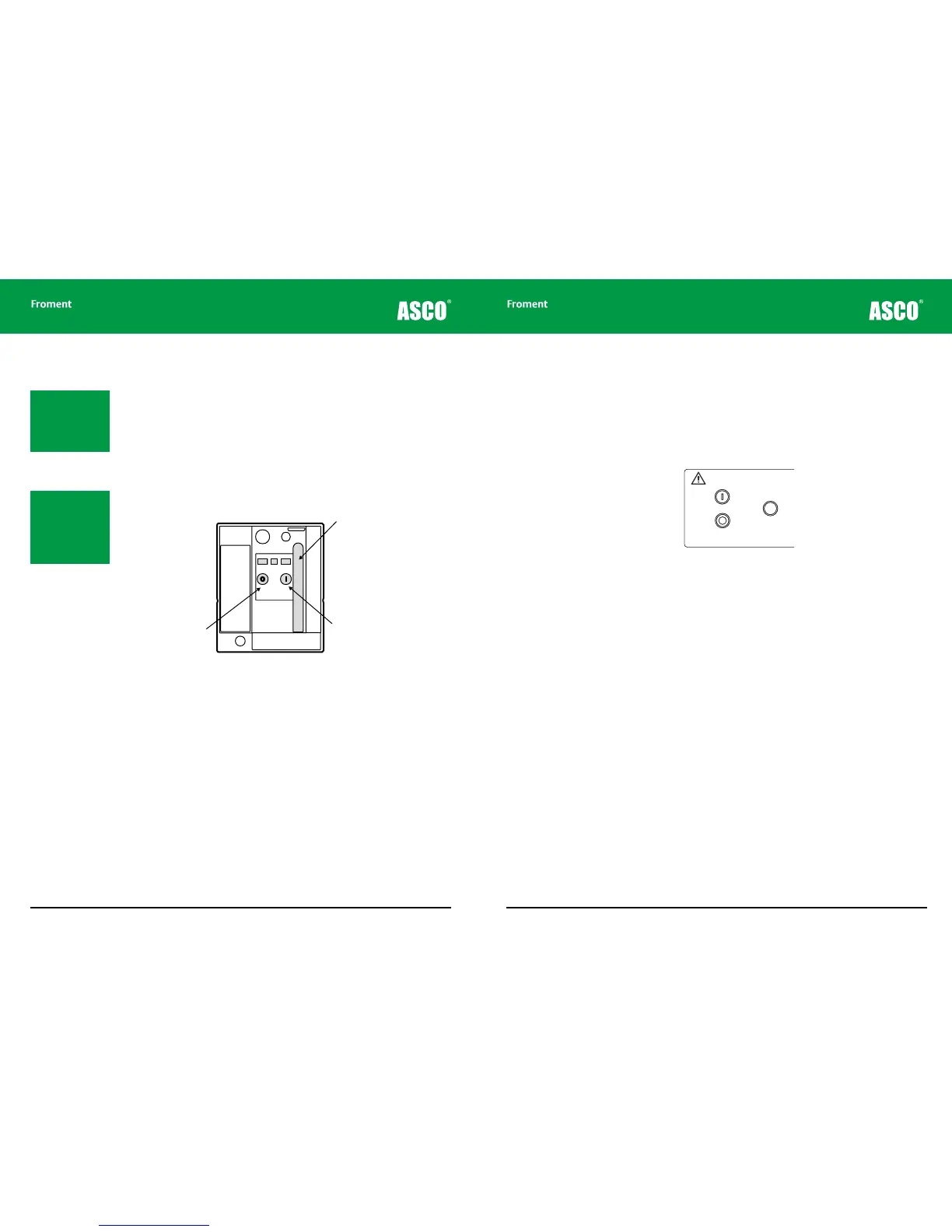

Figure 3-4 ACB operating controls

Chapter Three

Spring motor

charging handle

Close contacts

button

3 - 9

Status indicator lamp operation

The control panel contains a number of status indicator lamps. These include a lamp (two

lamps in the case of the 8400) which indicates the status of the Air Circuit Breakers (ACBs).

There is also a lamp which indicates the status of the Supply-on-Test. The Start and Stop

indicator lamps, located in the Start and Stop/Reset push buttons, and the Supply-on-Test

status lamp work together to provide a visual indication of the load bank’s operational

status.

Figure 3-5 The Start and Stop indicator lamps located in the control panel push buttons.

When the load bank controls are first powered up all indicators will illuminate. This provides

a lamp test and indicates that the Sigma 2 processor’s self test sequence is running. When

the self-test sequence has completed successfully the Start lamp is extinguished and Stop

lamp will be illuminated steadily.

If the Air Circuit Breakers are closed the corresponding status lamps will light. If the

Supply-on-Test has been connected correctly the Supply-on-Test status lamp will also

glow steadily.

If no other lamps are lit the load bank is now operational and waiting for the Start button to

be pressed. Pressing the Start button activates the control system and will illuminate the

Start indicator. The Stop lamp will extinguish.

Fault Indicators

The indicators flash to provide a visual indication of faults detected by the Sigma controller.

Faults are classified as either a warning or as an error.

Errors. These are serious fault conditions which result in the load bank performing a

controlled shut down when they occur.

If an error occurs the Start indicator lamp will be extinguished and the Stop indicator

lamp will begin to flash. An error code will be displayed on Sigma controller LED (see See

“Sigma 2 Load Bank Status Display” on page 5-6 for more details). If an Hand-held unit or

PC system is connected to the load bank the error message will be displayed on the screen

(See “Sigma 2 Load Bank Status Display” on page 5-6 for more on this).

Load Bank Operation

Note: The spring motor

generates a loud noise

when opening and

closing the contacts.

This is normal operation

and does not indicate

a fault.

Note: When the ter-

minal link plates are

in use the contacts on

both ACBs should be

closed before any load

is applied.

PA10251

Warning!

High Leakage Current

The Frame of this equipment must be bonded to the

protective earth terminal of the supply on test.

A conductor of no less than half the total cross-sectional

area of the supply conductors should be used.

LOAD BANK NUMBER

When controlling more

than one load bank, each

must have a different

number set on this switch.

Sigma 2

Control

∑

All doors must be shut

and guards fitted before

running this equipment.

Remove load and allow

elements to cool before

stopping the fan.

START

STOP/

RESET

Supply-on-Test

Status

Circuit Breaker

#1

CLOSED

Circuit Breaker

#2

CLOSED

Voltage

Metering

Source

INT EXT

Off: No Voltage

On: Normal Operation

Flashing: Out of Limits

1

2

3

4

5

9

7

8

10

11

0

PA10251

Warning!

High Leakage Current

The Frame of this equipment must be bonded to the

protective earth terminal of the supply on test.

A conductor of no less than half the total cross-sectional

area of the supply conductors should be used.

LOAD BANK NUMBER

When controlling more

than one load bank, each

must have a different

number set on this switch.

Sigma 2

Control

∑

All doors must be shut

and guards fitted before

running this equipment.

Remove load and allow

elements to cool before

stopping the fan.

START

STOP/

RESET

Supply-on-Test

Status

Circuit Breaker

#1

CLOSED

Circuit Breaker

#2

CLOSED

Voltage

Metering

Source

INT EXT

Off: No Voltage

On: Normal Operation

Flashing: Out of Limits

1

2

3

4

5

9

7

8

10

11

0

Loading...

Loading...