2 - 14

Chapter Two

2 - 15

Load Bank Installation and Setup

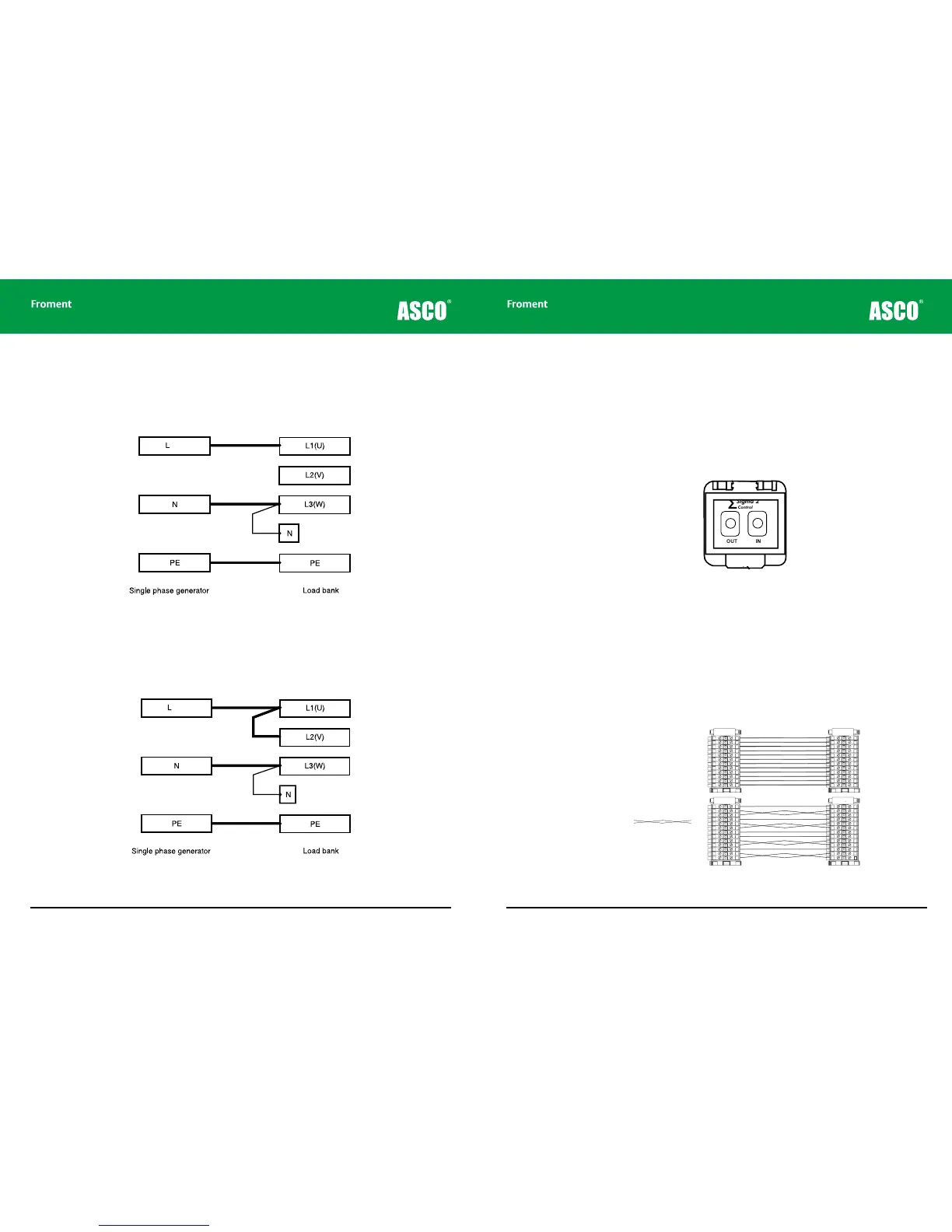

Basic Connection

The basic connection shown in Figure 2-6 will give approximately 50% loading capacity

when the nominal load bank supply voltage is connected or 17% loading capacity when a

230V single-phase supply is used.

Figure 2-6 Basic connection for a delta configured single phase supply

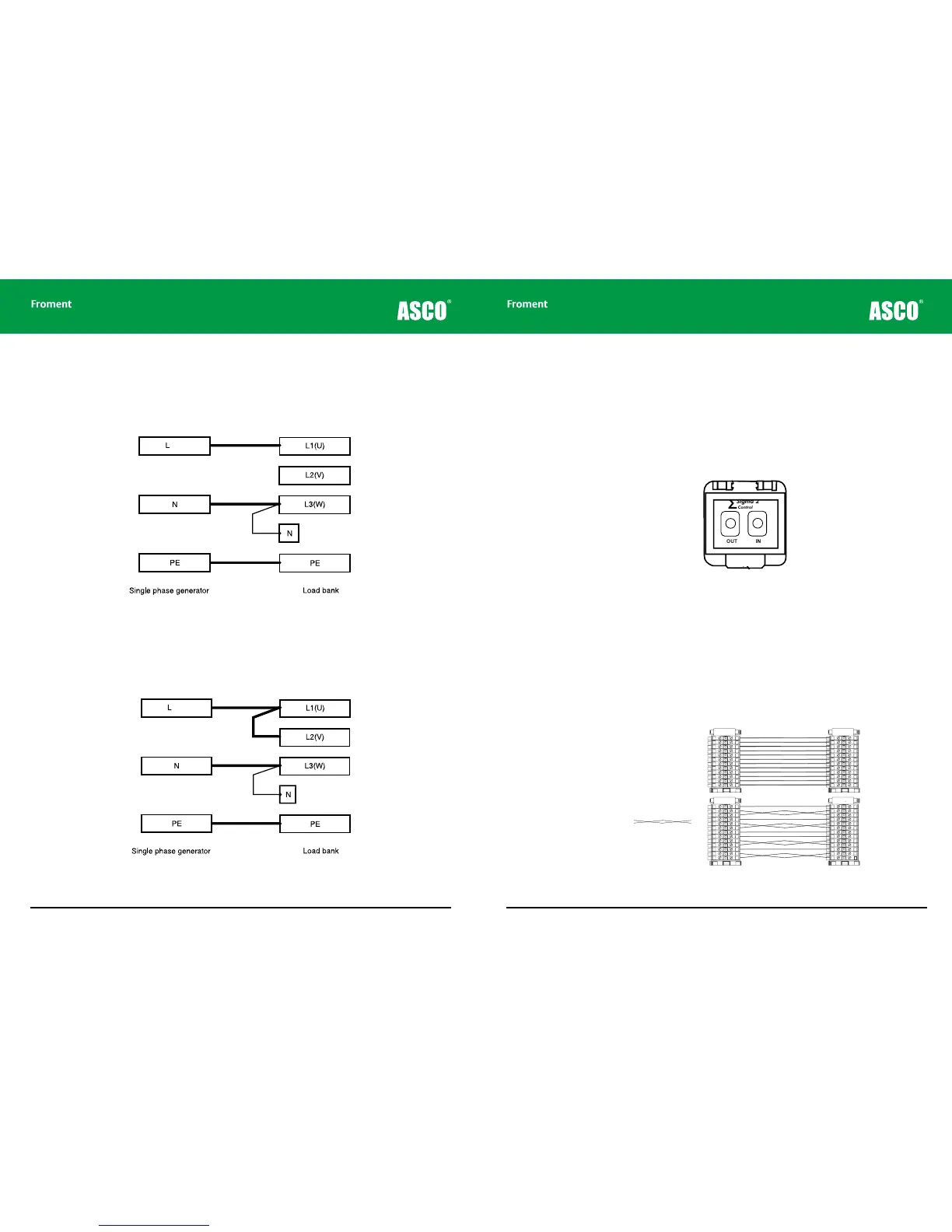

Alternative connection

The loading capacity can be increased by linking together L1 (U) and L2 (V) as shown in

Figure 2-7.

Figure 2-7 Alternative Delta configured connection for maximum loading

Instrumentation

neutral

Instrumentation

neutral

In this case the connection will provide approximately 67% loading capacity when a 400V

single-phase supply is connected or 22% loading capacity when a 230V single-phase

supply is used.

Control System Connections

Load banks are usually operated using a Sigma control device connected to the Sigma

Control cable socket on the control panel. To connect the Sigma device simply plug the

control system control cable in to the front panel socket.

Figure 2-8 The Sigma control cable connector.

Remote panels for static load banks

Some load bank installations include a remote control station This duplicates some of

the controls on the main control panel and provides sockets for connecting the Sigma 2

control cable.

Remote station control panels are connected to the load bank using a set of terminals which

are located in either the main power termination compartment or the control compartment

(refer to the supplied drawings for details of the specific location and wiring).

Figure 2-9 Typical wiring for a remote station control panel.

OUT IN

Sigma 2

Control

∑

Fan and controls

supply isolator (Emergency Stop)

Fan and controls

supply source

selector

Manual stop/start

buttons

Sigma control

interface cable

sockets (in/out)

Load bank

number selector

Supply on test

status indicator

LB00060

LOAD BANK NUMBER

When controlling more

than one load bank, each

must have a different

number set on this switch.

Sigma 2

Control

∑

All doors must be shut

and guards fitted before

running this equipment.

Remove load and allow

elements to cool before

stopping the fan.

START

STOP/

RESET

Warning!

Isolator for fan

and controls supply only.

Other supplies may enter this load

bank. Isolate all before working on

this equipment.

Select “Internal” only when the

Fan & Controls Supply Selector

supply-on-test equals the control circuit

rated voltage and frequency.

OFF ExternalInternal

Supply-on-Test

Status

Off: No Voltage

On: Normal

Operation

Flashing: Out of

Limits

Loading...

Loading...